Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

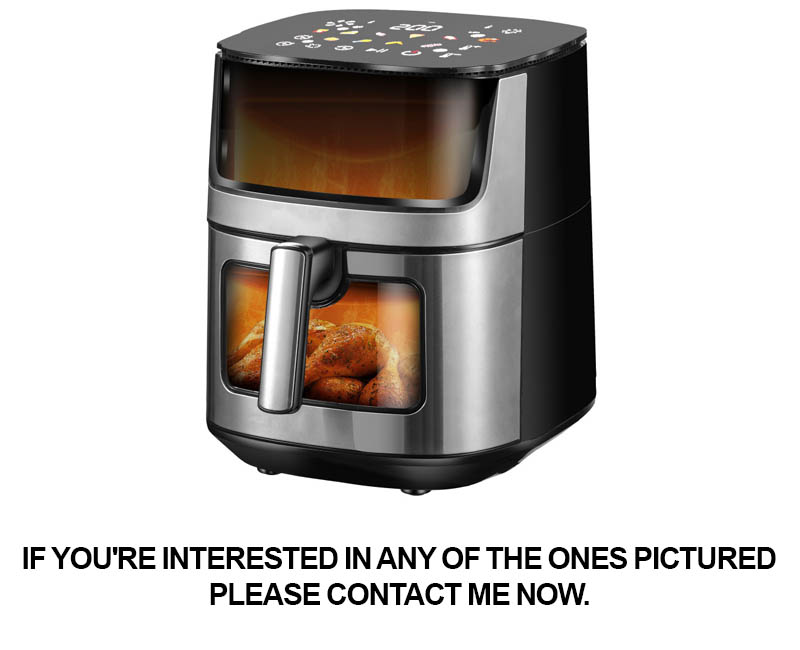

In the ever-evolving landscape of home appliances, the rise of smart kitchen technology has revolutionized the way we cook and live. Among these innovations, air fryers have surged in popularity, offering a healthier alternative to traditional frying methods. This surge has created a thriving market for OEM solutions, particularly those that adhere to stringent safety standards, such as UL certification. As we delve into the world of turnkey UL certified air fryer OEM solutions, it’s clear that embracing technology and understanding consumer preferences is key to success.

The Future of Cooking: Turnkey UL Certification Air Fryer OEM Solutions

In the ever-evolving landscape of kitchen appliances, the air fryer has emerged as a game-changer, promising healthier cooking options without compromising on taste. As we delve into the future of cooking, the concept of turnkey UL certification air fryer OEM solutions is not just a trend; it’s a revolution. This article explores how these solutions are shaping the industry and why they are becoming the cornerstone of modern kitchen innovation.

The rise of smart kitchen appliances has been meteoric, and air fryers are at the forefront of this culinary revolution. These devices use hot air to circulate around food, creating a crispy outer layer while reducing the need for oil. The convenience and health benefits have made them a staple in many households.

Turnkey solutions, in the context of air fryers, refer to a complete package that includes design, manufacturing, quality control, and certification. This means that a company can provide a fully operational air fryer, ready to be sold under their brand, without the need for extensive in-house resources or expertise.

The Importance of UL Certification

UL (Underwriters Laboratories) certification is a mark of safety and quality that consumers trust. For OEMs (Original Equipment Manufacturers) in the air fryer market, achieving UL certification is crucial. It not only ensures that the product meets stringent safety standards but also builds consumer confidence.

When an air fryer carries the UL certification, it means that it has been tested for electrical, thermal, and fire safety, among other factors. This certification is not just a legal requirement in many markets but also a testament to the manufacturer’s commitment to excellence.

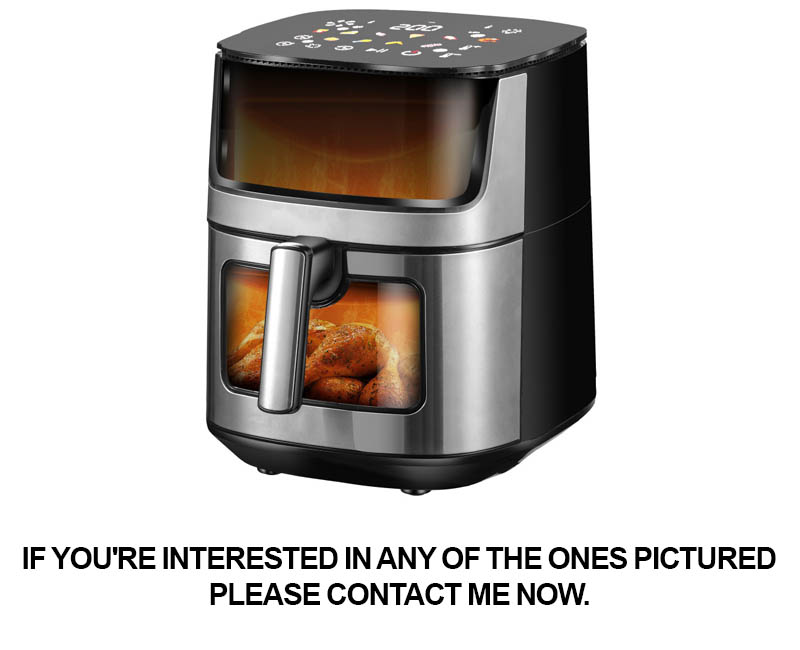

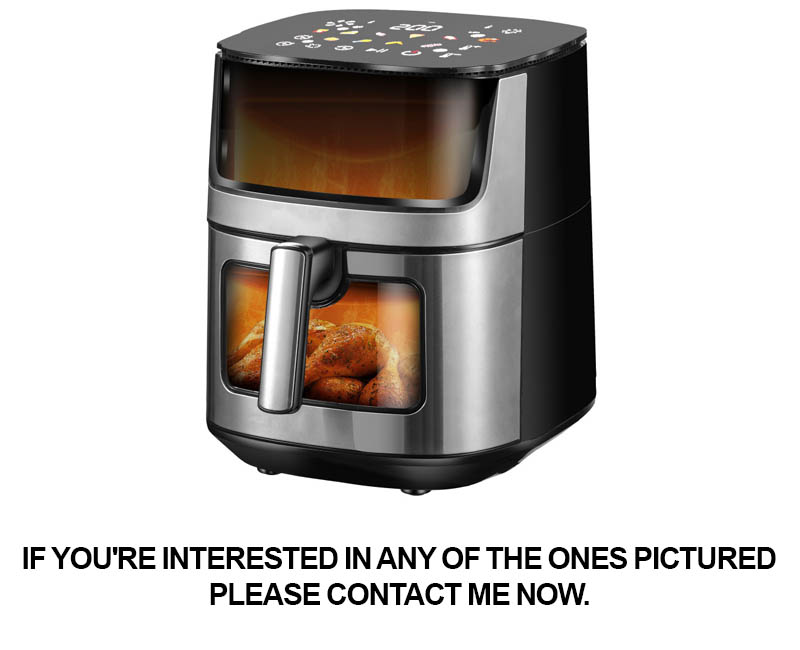

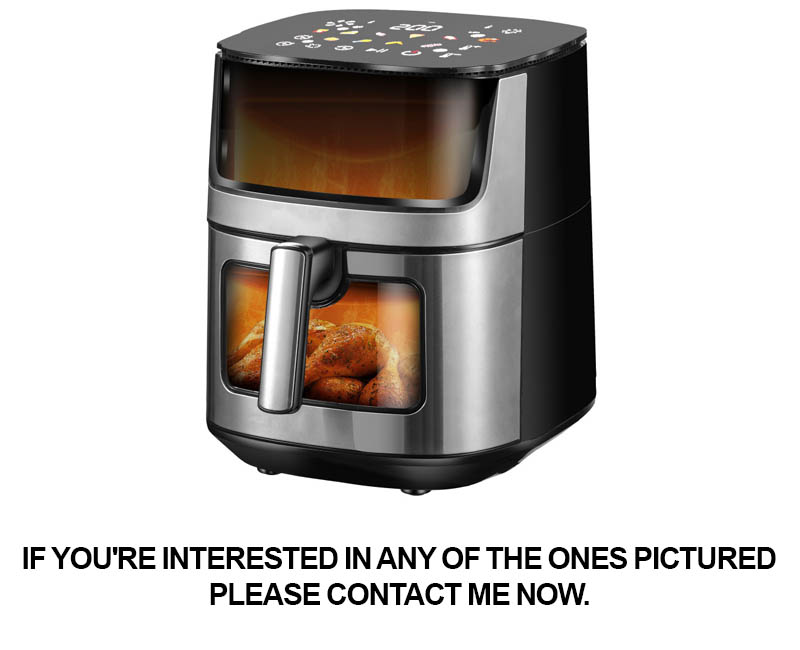

Innovative Air Fryer Designs

The air fryer market is no longer just about replicating traditional fryers. OEMs are now pushing the boundaries with innovative designs that cater to diverse consumer needs. From compact models for small kitchens to multi-functional units that can bake, roast, and grill, the variety is vast.

One of the latest trends in air fryer design is the integration of smart technology. This includes features like programmable settings, digital displays, and connectivity to smartphones for remote monitoring and control. These innovations not only enhance the user experience but also open up new opportunities for customization and convenience.

OEM Opportunities in the Air Fryer Market

The air fryer market is ripe with opportunities for OEMs. With the increasing demand for healthier cooking options, there’s a constant need for new and improved models. OEMs can capitalize on this trend by offering custom solutions that cater to specific market segments.

Collaborating with brands that are looking to expand their product lines is another avenue for growth. By providing turnkey solutions, OEMs can help these brands enter the air fryer market quickly and efficiently, leveraging their expertise in design and manufacturing.

Market Trends and Consumer Preferences

Understanding market trends and consumer preferences is key to the success of any OEM in the air fryer market. Currently, there’s a growing preference for energy-efficient appliances that are easy to clean and maintain. Consumers are also looking for appliances that offer versatility and can be used for a variety of cooking methods.

Additionally, the trend towards eco-friendly and sustainable products is influencing the design and materials used in air fryers. OEMs that can integrate these considerations into their products will have a competitive edge.

Case Study: Successful Turnkey Air Fryer Projects

Several companies have successfully implemented turnkey air fryer projects, showcasing the potential of this business model. One such example is a partnership between an OEM and a well-known kitchen appliance brand. The collaboration resulted in a range of air fryers that were not only UL certified but also featured innovative designs that resonated with consumers.

The success of these projects can be attributed to a combination of factors, including thorough market research, advanced manufacturing capabilities, and a focus on quality control. By streamlining the production process, OEMs can deliver products that meet the highest standards of safety and performance.

The Role of Technology in Air Fryer Development

Technology plays a pivotal role in the development of air fryers. From the materials used in the construction to the software that controls the cooking process, technological advancements are driving innovation in the industry.

For example, advancements in heating elements have allowed for more precise temperature control, which is essential for achieving the perfect crispness without overcooking. Similarly, the integration of IoT (Internet of Things) technology has made air fryers smarter and more connected, enhancing the user experience.

Conclusion: Seizing the Market with Turnkey UL Certified Air Fryers

As the demand for healthier cooking solutions continues to grow, turnkey UL certification air fryer OEM solutions are poised to play a significant role in shaping the future of the kitchen. By offering a complete package that includes design, manufacturing, and certification, OEMs can provide brands with a competitive edge in the market.

For consumers, this means access to high-quality, safe, and innovative air fryers that make cooking healthier and more enjoyable. As the industry evolves, those who embrace turnkey solutions and continue to push the boundaries of technology will be at the forefront of the culinary revolution.

In the ever-evolving landscape of home appliances, the kitchen has become a hub of innovation and convenience. Smart kitchen appliances are not just a trend; they are revolutionizing the way we cook and live. From simple toasters to complex robotic ovens, these devices are designed to enhance our daily routines and make cooking more enjoyable and efficient.

The integration of technology into kitchen appliances has brought about a new era of culinary experiences. Smart ovens, for instance, can now be controlled remotely via smartphones, allowing users to start or finish cooking tasks while on the go. The rise of these smart kitchen appliances is driven by several factors, including increased consumer demand for convenience, health consciousness, and the desire for personalized experiences.

Health-conscious consumers are gravitating towards appliances that can help them prepare healthier meals. Air fryers, in particular, have gained popularity for their ability to cook food with less oil, making them a favorite among those looking to reduce their fat intake. These appliances use hot air to circulate around the food, creating a crispy outer layer while keeping the inside tender and juicy.

The kitchen has also become a space for social interaction, and smart appliances are designed to facilitate this. Multi-functional cookers, for example, can handle a variety of cooking methods, from grilling to steaming, making them perfect for entertaining guests. These devices often come with intuitive interfaces and interactive features that can guide users through complex recipes with ease.

Moreover, the advent of voice-activated technology has made kitchen appliances even more accessible. Devices like the Amazon Echo and Google Home can be connected to kitchen appliances, allowing users to control them with simple voice commands. This not only adds a touch of futuristic flair to the kitchen but also caters to those with physical limitations or busy hands.

Manufacturers are responding to these changes by investing heavily in research and development. They are creating appliances that not only save time but also provide valuable insights into how we use them. Smart kitchen appliances can track cooking times, energy consumption, and even suggest recipes based on the ingredients you have on hand. This level of personalization is changing the way we approach meal preparation.

The rise of smart kitchen appliances is also influenced by the growing trend of urbanization. As more people move to cities, they often find themselves living in smaller spaces where traditional appliances might not fit. Compact, efficient, and smart appliances are becoming the norm, offering a practical solution for city dwellers who still want to enjoy the benefits of a well-equipped kitchen.

In the realm of smart kitchen appliances, the competition is fierce, but it’s also driving innovation. Companies are constantly pushing the boundaries of what’s possible, from energy-efficient designs to sustainable materials. The result is a market that is both diverse and dynamic, with new products and features being introduced regularly.

As we look to the future, it’s clear that the smart kitchen appliance sector is poised for continued growth. The next wave of innovation may include appliances that can predict meal preferences, integrate with other smart home systems, and even adapt to changes in household dynamics. The possibilities are virtually limitless, and the kitchen is at the forefront of this technological revolution.

In conclusion, the rise of smart kitchen appliances is a testament to the power of technology to improve our daily lives. As these devices become more sophisticated and integrated into our homes, they will continue to shape the way we cook, interact, and live. The future of cooking is not just about convenience; it’s about creating a more connected and efficient kitchen that caters to the evolving needs of consumers.

In the ever-evolving landscape of the kitchen appliance industry, the concept of turnkey solutions has emerged as a game-changer for manufacturers and consumers alike. A turnkey solution, in essence, is a comprehensive package that includes everything needed to launch a product or service, from design and engineering to manufacturing and certification. This approach simplifies the process, reduces costs, and ensures a high-quality end product. Let’s delve into what makes a turnkey solution so compelling.

The cornerstone of a turnkey solution lies in its all-encompassing nature. It encompasses not just the physical product, but also the entire lifecycle of the product, from conception to delivery. This means that when a company opts for a turnkey solution, they are essentially outsourcing the entire process to a single provider. This provider is responsible for every detail, from sourcing raw materials to final assembly, ensuring that the product meets all necessary standards and regulations.

One of the most significant advantages of turnkey solutions is the efficiency they bring to the table. By centralizing the production process, companies can streamline operations and reduce overhead. This streamlined approach also minimizes the risk of delays, as all aspects of production are managed by a single entity. For manufacturers looking to enter new markets or expand their product lines, turnkey solutions offer a fast and reliable path to market.

Customization is another key aspect of turnkey solutions. While the basic concept is to provide a complete package, these solutions often allow for a degree of customization to suit the specific needs of the client. This can include modifications to the design, the inclusion of additional features, or even branding changes. The ability to tailor the product to the client’s requirements ensures that the end result is not only functional but also appealing to the target market.

In the realm of kitchen appliances, the turnkey approach is particularly valuable. It allows manufacturers to focus on their core competencies, such as innovation and brand development, while leaving the intricate details of manufacturing and compliance to experts in the field. This division of labor can lead to a more cohesive and cohesive product, as each aspect is handled by professionals who specialize in that area.

The term “turnkey” also implies a high level of service and support. Turnkey providers are typically responsible for not just the production but also the after-sales service, including warranty and customer support. This comprehensive support network is crucial for ensuring customer satisfaction and maintaining the reputation of the brand.

When it comes to certification, turnkey solutions play a pivotal role. In many industries, including kitchen appliances, compliance with certain standards is mandatory. For example, the Underwriters Laboratories (UL) certification is a mark of quality and safety that is highly regarded in the United States and internationally. A turnkey provider that offers UL certification as part of their solution ensures that the product meets these stringent safety and performance criteria.

The process of obtaining UL certification can be complex and time-consuming. It involves rigorous testing and evaluation to ensure that the product is safe for use and complies with all relevant regulations. By including this certification as part of their turnkey package, providers take the burden off the manufacturer, allowing them to focus on other aspects of their business.

Moreover, turnkey solutions often come with a wealth of experience and knowledge. Providers who specialize in turnkey services have a deep understanding of the industry’s best practices, regulatory requirements, and market trends. This expertise can be invaluable in guiding manufacturers through the certification process and ensuring that their product stands out in a crowded market.

In addition to UL certification, turnkey solutions may also include other certifications, such as Energy Star, which is a symbol of energy efficiency. These certifications not only enhance the product’s credibility but also open up new markets and consumer segments.

The financial aspect of turnkey solutions is also worth considering. By handling the manufacturing, compliance, and certification processes, turnkey providers can often offer more competitive pricing. This can be a significant cost-saving for manufacturers, especially those who are new to the market or dealing with high-volume production.

In conclusion, turnkey solutions in the kitchen appliance industry offer a multitude of benefits. They provide a streamlined, efficient, and customizable approach to product development and manufacturing, while also ensuring compliance with safety and quality standards. With the expertise and support of a turnkey provider, manufacturers can focus on what they do best, leaving the complexities of production and certification to the experts. As the demand for smart kitchen appliances continues to grow, turnkey solutions are poised to play a crucial role in shaping the future of cooking.

In today’s fast-paced world, where convenience and safety are paramount, the importance of UL certification for kitchen appliances, such as air fryers, cannot be overstated. This certification serves as a mark of excellence, ensuring that these devices meet rigorous safety standards. Let’s delve into why UL certification is crucial for the air fryer OEM market.

The UL (Underwriters Laboratories) is a global independent safety science company that has been around since 1894. Their certifications are recognized worldwide, providing consumers with a sense of security when purchasing electrical products. When an air fryer carries the UL mark, it signifies that it has been tested and complies with a comprehensive set of safety regulations.

One of the key reasons for the importance of UL certification is the assurance it provides against electrical hazards. Air fryers, being electrical appliances, can pose risks if they are not designed and manufactured with safety in mind. UL certification ensures that the appliance has passed stringent testing for electrical shock protection, grounding, and insulation to prevent any potential accidents.

Another critical aspect of UL certification is its focus on fire safety. Air fryers operate at high temperatures and involve the use of flammable oils, making fire risk a significant concern. The certification process includes tests for material flammability, heat release, and burn prevention. This ensures that the air fryer is less likely to catch fire or contribute to a fire if it does occur.

Moreover, the certification process examines the structural integrity of the appliance. Air fryers often have moving parts and are subjected to various stresses during operation. UL certification ensures that the product can withstand these stresses without compromising its safety or performance.

Consumer confidence is also a major factor influenced by UL certification. With the plethora of air fryer models available on the market, consumers are often uncertain about which product is the safest and most reliable. The presence of the UL mark serves as a trust signal, indicating that the appliance has been vetted by a reputable third-party organization.

From a regulatory standpoint, UL certification is essential for compliance with various local and international standards. This is particularly important for OEMs (Original Equipment Manufacturers) that export their products globally. By obtaining UL certification, OEMs can ensure that their air fryers meet the safety requirements of different markets, reducing the risk of recalls and legal issues.

For OEMs looking to differentiate their products in a crowded market, UL certification can be a significant selling point. It not only highlights the safety features of the air fryer but also positions the brand as a leader in innovation and quality. This can lead to increased customer loyalty and market share.

Additionally, UL certification can extend the lifecycle of an air fryer. By ensuring that the appliance is free from potential safety hazards, consumers are more likely to trust the brand and continue purchasing their products over time. This long-term customer relationship is invaluable for OEMs looking to establish a strong presence in the market.

In terms of the certification process itself, it is a comprehensive and meticulous affair. It involves extensive testing, including electrical, thermal, mechanical, and fire safety evaluations. This process not only ensures compliance with safety standards but also encourages OEMs to continually improve their products.

Lastly, the UL certification process can lead to valuable insights for OEMs. As part of the certification, manufacturers receive feedback on their product’s performance and potential areas for improvement. This information can be used to enhance the design, materials, and manufacturing processes, ultimately leading to a safer and more efficient air fryer.

In conclusion, the importance of UL certification for air fryers cannot be overstated. It not only ensures compliance with safety standards but also builds consumer trust, facilitates global market access, differentiates products in a competitive market, and provides valuable feedback for continuous improvement. For OEMs looking to thrive in the air fryer industry, investing in UL certification is a strategic move that can yield significant returns.

Air fryers have evolved far beyond their initial concept of a healthier alternative to deep-frying. Today, they represent a cornerstone of modern kitchen technology, and their designs have become a testament to innovation and convenience. Here’s a closer look at the innovative aspects of air fryer designs:

The sleek, modern aesthetics of air fryers are a significant departure from the traditional kitchen gadgets of yesteryears. Many models now boast a streamlined look with rounded edges and a variety of colors that can complement any kitchen decor. The design not only enhances the visual appeal but also contributes to a more user-friendly experience.

One of the most innovative features in air fryer designs is the ease of use. Modern air fryers often come with intuitive interfaces, featuring digital displays or simple dials that allow users to select cooking modes and times with a touch or a twist. This user-friendly approach makes it accessible for everyone, from tech-savvy individuals to those who are less comfortable with kitchen appliances.

The interior of an air fryer has also seen remarkable advancements. Many models now feature non-stick coatings that are not only easy to clean but also durable. This not only simplifies the cleaning process but also extends the life of the appliance. Some air fryers even have removable baskets, making it easier to transfer food directly from the fryer to a serving dish without the need for utensils.

Air fryers have become more versatile with innovative designs that allow for multi-functional cooking. Some models come with additional features like a rotisserie function, which can roast and crisp meats, or a dehydrator setting for making healthy snacks. These multi-functional capabilities mean that users can replace several kitchen appliances with a single air fryer, saving space and reducing clutter.

The size and shape of air fryers have also been reimagined for better efficiency. Compact models are perfect for small kitchens or for those who want to save counter space. On the other hand, larger air fryers can accommodate larger batches of food, making them ideal for families or for entertaining. The design of the cooking chamber has been optimized to ensure that hot air circulates evenly, resulting in perfectly cooked food every time.

Safety has been a key focus in the design of modern air fryers. Many models include features like automatic shut-off and overheat protection to prevent accidents. The design of the fryer’s exterior is often heat-resistant, reducing the risk of burns when handling the appliance. Additionally, some air fryers come with safety locks to prevent accidental operation, which is especially important for households with children.

Innovation in air fryer design has also led to more energy-efficient models. These appliances use a fraction of the electricity compared to traditional deep-frying methods, which not only saves money on energy bills but also contributes to a greener, more sustainable lifestyle.

The design of air fryers has also embraced the principles of ergonomics. Handles are designed to provide a comfortable grip, and the weight of the appliance is often balanced to prevent slippage. The placement of buttons and controls is thoughtfully arranged to minimize the risk of accidental presses and to make adjustments during cooking as seamless as possible.

Lastly, the integration of smart technology in air fryer designs has opened up a new world of possibilities. With WiFi connectivity and companion apps, users can control their air fryers remotely, receive cooking notifications, and even access a library of recipes. The design of these smart air fryers has made it possible to enjoy the benefits of technology in the comfort of one’s kitchen.

In summary, the innovative designs of air fryers have transformed the way we cook, offering a healthier, more convenient, and efficient option for the modern kitchen. From their sleek appearance to their smart functionalities, air fryers continue to push the boundaries of what we expect from kitchen appliances.

In the ever-evolving landscape of kitchen appliances, the air fryer market has seen a surge in demand, presenting a wealth of opportunities for Original Equipment Manufacturers (OEMs). Here’s a closer look at the various avenues and strategies that OEMs can explore to capitalize on this burgeoning sector.

The air fryer’s popularity is not just a fleeting trend; it’s a testament to the public’s quest for healthier cooking alternatives. Consumers are increasingly looking for appliances that can deliver crispy, delicious fried foods with minimal oil, making air fryers a compelling choice. For OEMs, this means there’s a significant market to tap into, with a variety of opportunities for customization and innovation.

One key opportunity lies in the customization of air fryer models to cater to specific market segments. For instance, there’s a growing trend towards eco-friendly and sustainable products, which OEMs can address by using recyclable materials and energy-efficient designs. By aligning with these values, OEMs can attract environmentally conscious consumers and gain a competitive edge.

Another avenue is the integration of smart technology. Smart air fryers that can be controlled via smartphone apps or voice assistants are becoming more popular. These devices not only offer convenience but also provide users with the ability to monitor and adjust cooking times and temperatures remotely. For OEMs, this means developing partnerships with tech companies to embed smart features into their air fryers, thus appealing to tech-savvy consumers.

Customization isn’t just about features; it’s also about design. The aesthetic appeal of an air fryer can be a significant factor in its success. OEMs can explore sleek, modern designs that fit seamlessly into contemporary kitchen settings. Additionally, compact and portable models are in demand, as they cater to consumers who have limited space or a desire for convenience. This could involve the development of foldable or collapsible fryers that are easy to store and transport.

The market also offers opportunities for innovation in functionality. For example, air fryers with built-in filters to trap grease and odors, or those that offer multi-cooking capabilities, such as roasting, baking, and grilling, are becoming more sought after. OEMs can differentiate their products by introducing unique features that address common pain points, such as easier cleaning or more intuitive controls.

In terms of branding, OEMs have the chance to establish themselves as leaders in the air fryer market. By focusing on quality, durability, and customer satisfaction, brands can build a reputation for reliability. This is crucial in a market where consumer trust is paramount, especially when it comes to appliances that involve cooking and food safety.

Collaborations with local and international retailers can also open doors for OEMs. Distributing products through well-known stores and online platforms can increase visibility and accessibility. OEMs might consider exclusive deals with certain retailers, which can lead to dedicated product lines and marketing campaigns.

Moreover, the global reach of the air fryer market is vast. OEMs can explore exporting their products to regions where air fryers are not yet mainstream, such as certain parts of Asia and Africa. This requires understanding local preferences and regulations, but it can be a lucrative strategy for expanding market share.

The air fryer market is also ripe for collaborations with foodservice providers. OEMs can develop commercial-grade air fryers tailored to the needs of restaurants and cafes. These models might include features like rapid heating and cooling, or the ability to handle high volumes of food at once.

In the realm of sustainability, OEMs can look into the lifecycle of their products. This involves considering how the air fryers are manufactured, how they are used, and how they can be responsibly disposed of or recycled at the end of their life. By offering repair services, recycling programs, or eco-friendly packaging, OEMs can appeal to consumers who are increasingly concerned about the environmental impact of their purchases.

Lastly, OEMs should stay abreast of the latest trends in the food industry. For instance, there’s a growing interest in plant-based diets, which could lead to the development of air fryers specifically designed for cooking vegetables and vegan-friendly foods. By keeping a finger on the pulse of the market, OEMs can anticipate future demand and position themselves as forward-thinking innovators.

The air fryer market presents a myriad of opportunities for OEMs, from customization and design to smart technology integration and global expansion. By focusing on these areas, OEMs can carve out a niche for themselves and contribute to the ongoing evolution of the kitchen appliance industry.

In the ever-evolving landscape of kitchen appliances, understanding market trends and consumer preferences is crucial for manufacturers looking to innovate and capture market share. Here’s a closer look at the dynamics shaping the air fryer market:

The Shift Towards Healthier Cooking MethodsConsumers are increasingly conscious of their health and are seeking cooking methods that offer healthier alternatives to traditional frying. Air fryers have gained popularity due to their ability to cook food with less oil, reducing the calorie count and potential for heart disease. This shift has opened up a new wave of opportunities for OEMs to develop air fryers that cater to these health-conscious consumers.

Smart Technology IntegrationAs technology advances, so does the expectation for smart features in kitchen appliances. Consumers are now looking for air fryers that not only cook food efficiently but also offer connectivity to smartphones and smart home systems. This integration allows users to monitor cooking times, adjust settings remotely, and even receive notifications when their meal is ready. OEMs that can offer these smart features are likely to see a significant boost in their product lines.

Design and AestheticsThe aesthetic appeal of kitchen appliances has become a critical factor in consumer purchasing decisions. Air fryers that are sleek, modern, and stylish are more likely to catch the eye of potential buyers. OEMs are exploring designs that not only look good but also offer practicality, such as removable baskets for easy cleaning and non-stick surfaces that reduce the need for additional cooking sprays.

Sustainability and Eco-Friendly MaterialsWith growing environmental concerns, consumers are more likely to support brands that prioritize sustainability. OEMs are responding by using eco-friendly materials in their air fryers, such as biodegradable packaging and energy-efficient components. This not only aligns with consumer values but also opens up new markets for those who can produce eco-conscious products.

Portability and Compact SizeAs urban living becomes more prevalent, so does the need for compact kitchen appliances. Consumers are looking for air fryers that are not only efficient but also portable, allowing them to cook meals in smaller spaces. This trend has led to the development of smaller, travel-sized air fryers that can be easily stored and transported, appealing to both young professionals and frequent travelers.

Customization and PersonalizationThe ability to customize and personalize products is becoming a key driver in consumer preferences. OEMs are now offering air fryers with a variety of cooking programs, allowing users to choose from a range of settings for different types of food. Additionally, some manufacturers are exploring modular designs where consumers can add accessories to their air fryers, creating a more versatile cooking experience.

Health and Safety FeaturesSafety is always a top priority, and the air fryer market is no exception. Consumers are looking for air fryers with safety features such as automatic shut-off, cool-touch handles, and child safety locks. OEMs that can innovate in this area are not only protecting their customers but also enhancing the perceived value of their products.

Price SensitivityWhile health and technology are important, price remains a significant factor in consumer purchasing decisions. OEMs must balance innovation with affordability to appeal to a broader market. This often means finding cost-effective manufacturing processes and materials without compromising on quality or safety.

Cultural Diversity and International MarketsThe air fryer market is not limited to any one region; it’s a global trend. OEMs that can adapt their products to cater to different cultural preferences and dietary restrictions are better positioned to succeed in international markets. This includes considering various cooking techniques and ingredients that are popular in different countries.

In conclusion, the air fryer market is ripe with opportunities for OEMs that can keep pace with market trends and consumer preferences. By focusing on health, technology, design, sustainability, and affordability, manufacturers can develop products that not only meet but exceed consumer expectations, ultimately driving growth and success in this dynamic sector.

In the bustling world of kitchen appliances, there are stories of innovation and success that stand out. One such tale is the journey of the Turnkey Air Fryer Projects, a series of ventures that have not only redefined the market but also set new standards for quality and efficiency. Let’s delve into the details of these successful projects.

The first project, launched in a small, yet burgeoning market, aimed to introduce air fryers as a healthier alternative to traditional deep frying. The team behind the project recognized the growing consumer interest in health and wellness, and they capitalized on this trend by offering a product that promised reduced fat content without compromising on taste. The design was sleek, the features were user-friendly, and the branding was catchy, making the air fryer an instant hit.

The second project involved a collaboration with a renowned OEM manufacturer to produce a line of air fryers that catered to both the domestic and commercial markets. The challenge was to create a product that could withstand heavy use while maintaining its compact and portable design. The result was a robust air fryer with a durable exterior and an efficient heating element that could quickly cook a variety of foods, from crispy French fries to succulent chicken wings.

A third project focused on integrating smart technology into the air fryer experience. The team developed a range of models that could be controlled via a smartphone app, allowing users to monitor cooking times and temperatures remotely. This innovation was met with enthusiasm, as consumers sought out appliances that could offer convenience alongside their health benefits. The project’s success was a testament to the power of technology in enhancing everyday cooking.

In another instance, a project targeted the eco-conscious consumer by creating an air fryer made from sustainable materials. The design was not only eco-friendly but also visually appealing, with a rustic charm that appealed to those looking for a greener kitchen solution. The project’s commitment to sustainability resonated with a niche market segment, leading to strong sales and positive feedback.

One particularly successful project involved a partnership with a local food service provider to create a commercial-grade air fryer. The appliance was designed to handle high-volume cooking, with features like a large capacity basket and a quick-cook setting. The result was a game-changer for the food service industry, offering a healthier option for patrons while reducing operational costs for businesses.

Another notable project was a collaboration with a global brand to develop a line of air fryers that combined traditional aesthetics with modern technology. The design team drew inspiration from classic kitchen appliances, creating a range that was both functional and stylish. The project’s success can be attributed to its ability to bridge the gap between nostalgia and innovation, appealing to a broad audience.

In a bid to cater to the health-conscious consumer, a project focused on creating an air fryer that could cook a variety of dishes, from vegetables to desserts, with minimal oil. The team developed a unique air circulation system that ensured even cooking without the need for excessive oil. This product was a hit with health enthusiasts and those looking to adopt a more balanced diet.

A project aimed at the budget-conscious consumer resulted in a line of affordable air fryers that offered the same benefits as their high-end counterparts. The team worked tirelessly to optimize costs without compromising on quality, ensuring that the product was accessible to a wider market. The affordability of the air fryers helped to drive sales and establish the brand as a leader in the value segment.

In one final project, the team focused on creating an air fryer that could be customized to the user’s specific needs. The appliance featured a modular design that allowed users to swap out components for different cooking functions, such as a dehydrator or a rotisserie. This level of personalization was a hit with consumers who wanted a versatile appliance that could grow with their culinary adventures.

The Turnkey Air Fryer Projects have proven that innovation and market research can lead to successful product development. Each project has brought something new to the table, from health-focused designs to smart technology and eco-friendly materials. These successes serve as a testament to the potential of the air fryer market and the opportunities that arise from a commitment to quality and customer satisfaction.

The integration of advanced technology has been pivotal in shaping the evolution of air fryers. From the initial concept of mimicking the frying process without oil to the sophisticated appliances we see today, technology has played a transformative role. Here’s a look into how tech has fueled the development of air fryers:

Smart Controls: Modern air fryers now come equipped with smart controls that allow users to customize their cooking experience. Features like adjustable temperature and time settings mean that users can achieve perfect results every time, whether they’re frying chicken, making fries, or baking desserts.

Heating Elements: The development of more efficient heating elements has significantly improved the performance of air fryers. Infrared heating and convection ovens have replaced the older models with a single heating element, providing more even cooking and faster results.

Temperature Sensors: To ensure consistent cooking, advanced air fryers incorporate precise temperature sensors. These sensors monitor the internal temperature of the air fryer and adjust the cooking settings accordingly, ensuring that food is cooked to the desired temperature without burning or undercooking.

User Interface: The user interface of air fryers has evolved from simple dials to sleek touchscreens. These interfaces not only enhance the aesthetic appeal but also offer a more intuitive and user-friendly experience. Users can now access a variety of pre-programmed settings and recipes at the touch of a button.

Material Improvements: The materials used in air fryer construction have also seen advancements. Non-stick coatings are now more durable and heat-resistant, reducing the risk of food sticking and the need for additional oil. Additionally, stainless steel and other premium materials have been introduced for exterior construction, enhancing the appliance’s lifespan and aesthetics.

Safety Features: With technology comes an increased focus on safety. Air fryers now feature safety locks to prevent accidental operation, automatic shut-off mechanisms to prevent overheating, and cool-touch surfaces to prevent burns. These features not only protect users but also contribute to the longevity of the appliance.

Energy Efficiency: Technology has also led to greater energy efficiency in air fryers. Newer models consume less electricity while still providing the same cooking performance, making them more eco-friendly and cost-effective.

Portability: Innovations in technology have made air fryers more portable than ever. Compact and lightweight designs allow users to take their air fryers on the go, perfect for camping trips, picnics, or those who prefer cooking in smaller spaces.

Healthy Cooking: One of the most significant contributions of technology to air fryer development is the promotion of healthier cooking. With the ability to cook food with minimal oil, air fryers have become a favorite among health-conscious consumers. The technology has made it easier for people to adopt healthier lifestyles without sacrificing taste.

Connectivity: Some of the latest air fryers now offer connectivity options, allowing users to control their appliances through smartphones or other devices. This connectivity isn’t just for convenience; it also opens up new possibilities for remote monitoring and control, making air fryers even more versatile.

Customization and Personalization: With technology, air fryers can be customized to suit individual preferences. From adjustable cooking times and temperatures to specific functions like pizza or popcorn modes, users can tailor their cooking experience to their liking.

Sustainability: Technology has also pushed the air fryer industry towards sustainability. As manufacturers seek to reduce their environmental footprint, they are exploring materials and manufacturing processes that are more eco-friendly.

In summary, the role of technology in air fryer development is multifaceted, ranging from enhancing performance and user experience to promoting health and sustainability. These technological advancements have turned the humble air fryer into a versatile, efficient, and healthy kitchen staple.

In the ever-evolving landscape of kitchen appliances, the air fryer has emerged as a game-changer, offering a healthier alternative to traditional frying methods. As the market continues to grow, the importance of turnkey UL certified air fryer OEM solutions cannot be overstated. These solutions not only ensure compliance with safety standards but also open up a world of opportunities for manufacturers and consumers alike. Here’s a look at how embracing these turnkey solutions can lead to a more robust, innovative, and consumer-centric market for air fryers.

The integration of smart technology has transformed the air fryer from a simple kitchen gadget to a multifunctional appliance that caters to modern lifestyles. From temperature control to automatic shut-off features, these advancements have made air fryers more user-friendly and efficient. As technology continues to advance, we can expect to see even more sophisticated features that enhance the cooking experience and make air fryers an indispensable part of any kitchen.

In the realm of OEM (Original Equipment Manufacturer) opportunities, the air fryer market presents a fertile ground for innovation. Companies that specialize in OEM solutions can tailor their products to meet the specific needs of various markets, from high-end consumers looking for premium features to budget-conscious shoppers seeking affordable options. The ability to customize designs, functionalities, and branding allows OEMs to carve out a niche in a highly competitive industry.

Market trends indicate a shift towards healthier eating habits, and air fryers are perfectly positioned to capitalize on this trend. Consumers are increasingly seeking out cooking methods that reduce fat and calories without compromising flavor. As such, the demand for air fryers has surged, and this upward trajectory is expected to continue. OEMs that can offer turnkey solutions that align with these preferences are in a prime position to capture a significant share of the market.

One compelling aspect of the air fryer market is its adaptability to various cultural tastes. For instance, while Western consumers might appreciate the ease of using an air fryer to prepare crispy French fries, Asian markets may gravitate towards air fryers that can cook dumplings or other traditional dishes. OEMs that can cater to these diverse culinary preferences are not only meeting consumer needs but also fostering brand loyalty.

A case study that exemplifies the success of turnkey air fryer projects is the partnership between a leading OEM and a global retailer. The OEM provided a comprehensive solution, from design to manufacturing, ensuring that the air fryers met stringent safety standards and were ready for market launch. The result was a highly successful product line that quickly became a top seller, thanks to its innovative features and competitive pricing.

The role of technology in air fryer development is undeniable. From the initial design phase to the final product, technology has been a driving force behind the evolution of air fryers. Advanced materials and manufacturing techniques have allowed for more energy-efficient units, while smart technology has made them more intuitive and versatile. For example, the introduction of wireless connectivity means users can monitor and control their air fryers remotely, adding a layer of convenience that is highly appealing to tech-savvy consumers.

In conclusion, the market for turnkey UL certified air fryer OEM solutions is ripe with potential. By focusing on innovation, customization, and safety, manufacturers can create products that resonate with consumers and stand out in a crowded marketplace. As the demand for healthier cooking options continues to rise, the air fryer market is poised for significant growth, and those who can offer turnkey solutions that meet these demands will be well-positioned to seize the market and lead the charge into the future of cooking.