Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Navigating the complexities of sourcing from a reliable air fryer factory can be daunting, but with a strategic approach, it becomes a journey filled with opportunities for growth and success. Whether you’re a small startup or a well-established brand, the key to a successful partnership lies in meticulous planning and thorough evaluation. In this segment, we delve into the intricacies of finalizing the agreement with your chosen supplier, ensuring that all aspects are covered and that the partnership is set to thrive.

Navigating the ever-evolving landscape of the air fryer market requires a keen understanding of the dynamics at play. To begin with, it’s essential to grasp the current trends that are shaping consumer preferences and influencing the industry. Here’s a closer look at the key aspects you need to consider:

Consumer Behavior Shifts: Today’s consumers are more health-conscious than ever before, leading to a surge in demand for kitchen appliances that offer healthier cooking options. Air fryers, with their ability to provide crispy, fried food with less oil, have become a popular choice. Understanding this shift in consumer behavior will help you identify the right market opportunities.

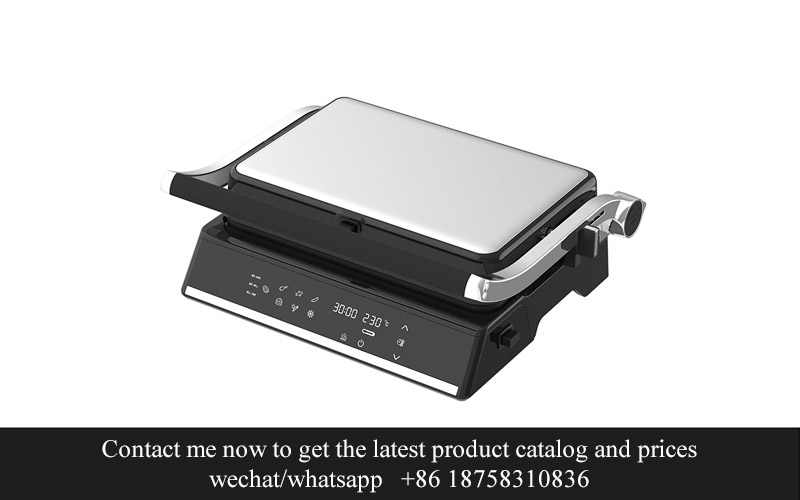

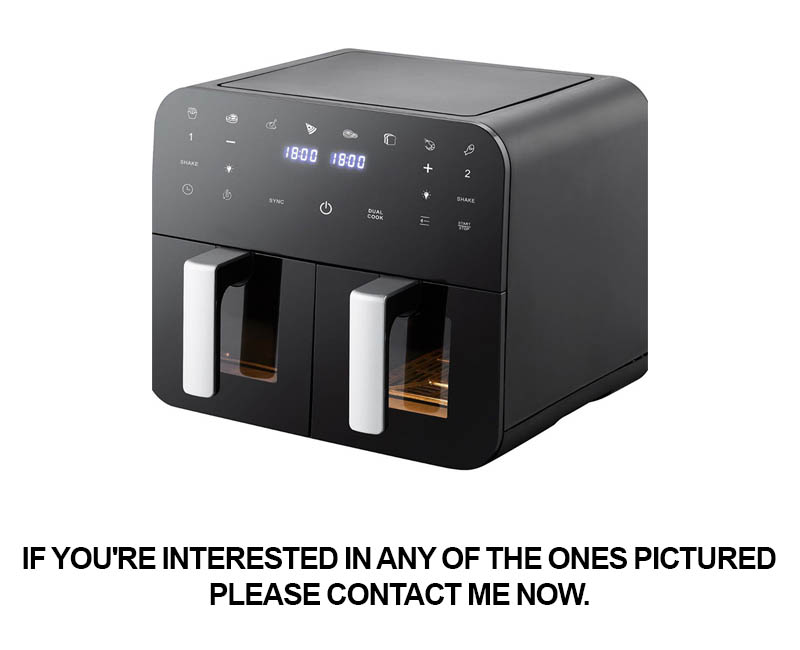

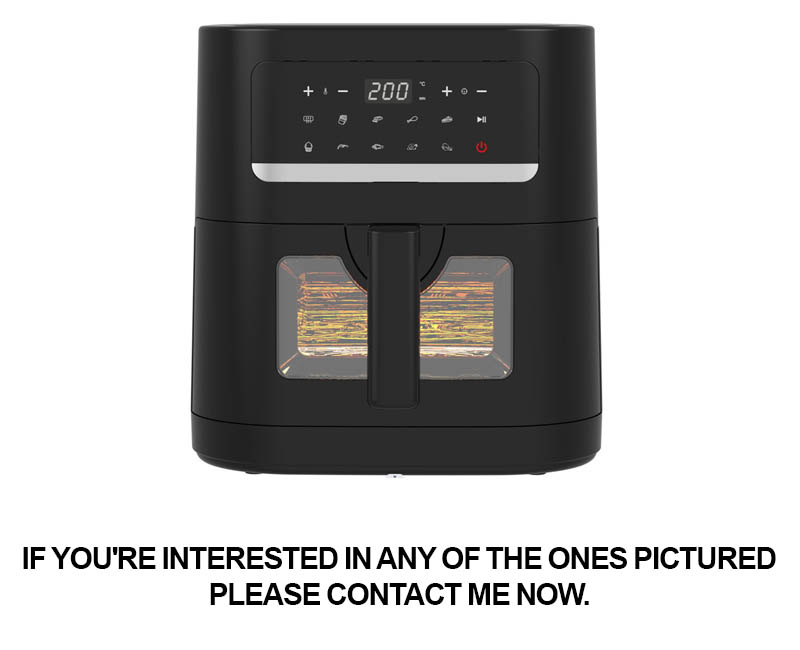

Technological Advancements: The air fryer industry is continually innovating, with new technologies emerging to enhance user experience and efficiency. From adjustable temperature controls to smart connectivity, staying abreast of these advancements is crucial. This knowledge will enable you to select a factory that can provide cutting-edge products.

Market Trends: Analyze the latest market trends to anticipate future demands. For instance, the trend towards eco-friendly and sustainable products is gaining traction. A factory that prioritizes sustainable practices and materials could be a better fit for your business.

Competitive Landscape: It’s important to know who your competitors are and how they are positioning their products. This includes understanding their pricing strategies, marketing tactics, and product features. This information will help you differentiate your offerings and identify gaps in the market that a reliable air fryer factory can fill.

Regulatory Environment: The air fryer market is subject to various regulations, including safety standards and environmental regulations. Being aware of these regulations is crucial to ensure that the factory you choose adheres to the necessary compliance measures.

Distribution Channels: Explore the different distribution channels available for air fryers, from online marketplaces to brick-and-mortar retailers. Understanding the most effective channels for reaching your target audience will inform your choice of factory partner.

Global Trends: Air fryers have become a global phenomenon, with varying levels of adoption in different regions. Study the international market to see how air fryers are being embraced in other countries, which can offer insights into potential growth opportunities.

Consumer Demographics: Analyze the demographics of air fryer buyers to tailor your product offerings. Consider age, income level, and lifestyle preferences to ensure that the factory you choose can cater to these diverse needs.

Branding and Marketing: The branding and marketing strategies employed by leading air fryer manufacturers can provide valuable insights. Look at how they position their products and what kind of messaging resonates with consumers.

Long-Term Growth Potential: Lastly, consider the long-term growth potential of the air fryer market. While the market is currently hot, it’s essential to partner with a factory that can scale its operations and adapt to future market shifts.

By thoroughly understanding these aspects of the market landscape, you’ll be better equipped to find a reliable air fryer factory that not only meets your current needs but also positions you for success in the dynamic and ever-growing air fryer industry.

To navigate the competitive landscape of the air fryer market, it’s crucial to have a clear understanding of your specific needs and expectations. This involves not just the technical specifications, but also the quality standards, design preferences, and scalability you’re aiming for. Here’s how to define your requirements for a reliable air fryer factory:

Identify Key Features and TechnologiesConsider the core functionalities that your air fryer must have. Are you looking for a model with a digital display, preset cooking modes, or a particular capacity? Determine if you need smart connectivity, such as Wi-Fi integration for remote control or monitoring. The technology inside the fryer, like the heating element and fan, also plays a significant role in the cooking performance and energy efficiency.

Consider Design and BrandingThe aesthetic appeal of the air fryer is important, especially if it will be sold under a specific brand. Think about the desired color, material, and overall design aesthetic. If your product is intended for a niche market or a particular demographic, the design should resonate with their preferences. Don’t forget to consider the branding elements that will be integrated into the design, such as logos or unique selling propositions.

Set Quality StandardsQuality is paramount in the kitchen appliances industry. Establish the quality benchmarks you expect from the air fryer, including the materials used, durability, and safety features. Consider certifications like CE, UL, or ETL that ensure the product meets international safety standards. You may also want to specify the expected lifespan of the product and the warranty terms that come with it.

Determine Capacity and SizeThe capacity of the air fryer will depend on your target market and intended use. Are you producing for a large-scale commercial kitchen or for home consumers? The size of the fryer will also impact its placement in the kitchen and the number of servings it can accommodate at one time. Be precise about the dimensions you need to ensure the product fits the intended space.

Energy Efficiency and Environmental ImpactIn an era of increasing environmental consciousness, the energy efficiency of the air fryer is a significant consideration. Specify the energy consumption levels and any eco-friendly features you want to include, such as automatic shut-off, energy-saving modes, or recyclable materials.

Customization OptionsIf you’re looking to differentiate your product, consider what level of customization you require. This could include specific colors, additional features, or even unique cooking capabilities. Discuss with the factory the extent to which they can tailor the product to your specifications without compromising quality or cost.

Production Volume and ScalabilityAssess your initial production volume and plan for scalability. If you anticipate rapid growth, ensure that the factory can handle increased orders without sacrificing quality. Discuss the production timeline, lead times, and the factory’s ability to scale up or down based on your needs.

Cost ConsiderationsBudget is a key factor in any business decision. Define your cost constraints and what you’re willing to pay for quality and customization. Be transparent about your budget to ensure that the factory can provide a solution that aligns with your financial goals.

Compliance with RegulationsEnsure that your air fryer meets all relevant regulatory requirements for your target market. This includes safety standards, labeling, and any other legal requirements. The factory should be able to provide documentation that their products comply with these regulations.

Long-Term Support and ServiceFinally, consider the long-term support and service you’ll need from the factory. This includes after-sales support, maintenance, and the availability of replacement parts. Establish clear expectations for ongoing communication and technical assistance to ensure a smooth partnership.

Navigating through the vast sea of suppliers can be daunting, but with a strategic approach, you can pinpoint the right partners for your air fryer manufacturing needs. Here’s how to embark on this crucial research phase:

By meticulously researching potential suppliers, you’ll be well-equipped to make an informed decision that aligns with your business goals and ensures a reliable supply chain for your air fryer products.

When delving into the world of air fryer manufacturers, it’s crucial to assess their factory capabilities to ensure they meet your quality standards and production needs. Here’s what you should look for:

Quality Control Systems– Inspect the factory’s quality control protocols to understand how they ensure each product meets industry standards.- Look for certifications like ISO 9001, which guarantees a systematic approach to quality management.- Ask about their inspection processes, from raw materials to finished goods, and how they handle defects.

Production Capacity– Determine the factory’s current production volume and their ability to scale up to meet your demands.- Inquire about their machinery and technology, as advanced equipment can significantly impact efficiency and output.- Consider their lead times and how quickly they can respond to increased orders.

Technology and Innovation– Evaluate the factory’s commitment to innovation by looking at their R&D capabilities.- Ask about any patents or proprietary technologies they use to differentiate their products.- Check if they invest in new technologies that could improve the efficiency or safety of their air fryers.

Workforce Expertise– The skill level of the workforce is key to the quality of the final product.- Look for training programs and certifications that the factory offers to its employees.- Consider the average tenure of the staff, as long-term employees often have more experience and knowledge.

Material Sourcing– Understand where the factory sources its materials and components.- Investigate their relationships with suppliers to ensure a reliable and consistent supply chain.- Look for evidence of sustainable sourcing practices, which can be a significant factor for many customers.

Environmental Compliance– Assess the factory’s environmental policies and practices.- Look for certifications like ISO 14001, which demonstrates a commitment to environmental management.- Consider the factory’s energy efficiency and waste management processes.

Safety Standards– Ensure the factory adheres to stringent safety standards for both the production process and the end product.- Check for certifications like OHSAS 18001, which focuses on health and safety management systems.- Ask about their emergency response procedures and how they handle accidents or incidents.

Customization and Flexibility– Determine if the factory can accommodate custom orders or modifications to their standard products.- Look for examples of past custom projects they have completed to gauge their ability to meet unique requirements.- Consider how adaptable they are to changes in design, materials, or production methods.

Financial Stability– Research the factory’s financial health to ensure they are a reliable partner.- Look for signs of stability, such as long-standing relationships with suppliers and a history of successful operations.- Consider their financial reports or ask for references from other clients.

Support and Service– Evaluate the level of customer support and service the factory provides.- Look for after-sales services, such as maintenance, repairs, and technical assistance.- Consider how they handle customer feedback and whether they have a dedicated customer service team.

By thoroughly examining these aspects of a factory’s capabilities, you can make an informed decision about whether they are the right partner for your air fryer manufacturing needs. Remember, a factory’s strengths in these areas will directly impact the quality, reliability, and success of your products in the market.

Understanding the specifications and materials used in the air fryer’s construction is crucial. Look for high-quality components like stainless steel for the fry basket and body, and non-stick coatings that are free from harmful chemicals. The durability and safety of these materials can significantly impact the longevity and performance of the product.

Inspect the design of the air fryer. Check for a user-friendly interface with clear controls and a simple-to-read display. The fryer should have a wide temperature range and a timer that allows for precise cooking. The presence of features like an auto shut-off or an adjustable fan speed can enhance the convenience and safety of the appliance.

Handle the product yourself to gauge its weight and balance. A well-designed air fryer should feel sturdy without being overly heavy or awkward to carry. The weight distribution can affect how easy it is to use the fryer, especially when transferring hot food or cleaning it after use.

Test the air fryer’s performance by cooking a sample dish. This step is essential to ensure that the fryer can achieve the desired results. Look for even cooking across all sections of the basket, with no cold spots or overcooked areas. The texture and flavor of the food should reflect the fryer’s ability to mimic traditional frying while using less oil.

Check the noise level of the air fryer during operation. While some noise is expected, a machine that is excessively loud can be and indicate poor insulation or design. A quieter unit can make cooking a more pleasant experience.

Examine the build quality of the air fryer. Look for signs of craftsmanship such as clean welds, tight seams, and a seamless finish. The quality of the plastics used should be high, with no visible cracks or poor fitting parts. A solid build not only ensures the longevity of the product but also gives you confidence in its safety.

Evaluate the ease of cleaning the air fryer. The fryer should have removable parts that are dishwasher safe, and the non-stick coating should make it easy to scrape off any residue. Check for a draining system or a catch tray to prevent oil spills and make cleanup even simpler.

Review the warranty and customer service policies. A reliable factory will offer a comprehensive warranty that covers both parts and labor. Additionally, their customer service should be responsive and ready to assist with any issues that may arise after the purchase.

Consider the after-sales support. A factory that stands behind its products will likely offer continued support, including technical assistance and maintenance tips. This can be a valuable resource for both you and your customers.

Finally, don’t hesitate to ask for additional information or demonstrations. A reputable supplier will be more than willing to provide further evidence of their product’s quality, such as test results or comparisons with competitors. This can give you a clearer picture of the air fryer’s capabilities and ensure that it meets your standards.

Understanding the comments and reviews from customers can be incredibly insightful when looking for a reliable air fryer factory. It’s like getting a glimpse into the experiences of those who have already worked with these manufacturers. Here’s how to sift through the feedback:

The Authenticity of Reviews

Quality of Products

Customer Service Experiences

Longevity and Repeat Business

Feedback from Various Channels

Comparative Analysis

The Tone of the Reviews

Engagement with the Community

The Overall Reputation

By thoroughly reviewing customer feedback and testimonials, you can gain valuable insights into the capabilities and reliability of an air fryer factory. This due diligence can help you make a more informed decision and avoid potential pitfalls in your supply chain.

Understanding the nuances of negotiation can be the difference between a successful partnership and a deal gone awry. When it comes to negotiating terms and conditions with a potential air fryer factory, here’s what you need to keep in mind:

Cost Analysis: Dive into the cost breakdown provided by the factory. Look beyond the initial quote to understand the components that contribute to the final price. Consider not just the unit cost but also any hidden fees or additional expenses that may arise during the production process.

Payment Structure: Negotiate the payment structure to align with your financial capabilities. This could involve discussing a payment plan, installment payments, or even exploring the possibility of a bulk purchase discount. Be clear about your preferred payment methods and the timelines for each payment stage.

Lead Times and Delivery: Clarify the lead times and delivery schedules. Factor in the production time, transportation, and any customs or import duties that might affect the delivery date. It’s crucial to ensure that the factory’s production capacity can meet your deadlines.

Quality Control: Insist on quality control measures and negotiate the specifics of how these will be implemented. This includes defining the standards for product inspection, any certifications required, and the process for handling defective items or returns.

Warranties and After-Sales Service: Negotiate the terms of warranties and after-sales service. Determine what is covered under the warranty, the duration of the warranty, and how claims will be processed. It’s also wise to discuss the availability and responsiveness of customer support.

Intellectual Property Rights: Protect your interests by negotiating intellectual property rights. This includes discussing who owns the designs, how they will be protected, and the rights the factory has to use your brand or product name.

Minimum Order Quantities (MOQs): Be aware of the factory’s MOQs and negotiate if possible. High MOQs can tie up capital and inventory space, so finding a balance that works for both parties is key.

Volume Discounts: If you plan to purchase in large quantities, negotiate for volume discounts. This can significantly reduce the overall cost per unit and improve your profit margins.

Changes and Modifications: Establish clear terms for any potential changes or modifications to the product after the initial agreement. This could include changes in design, materials, or specifications. Understand the costs and timeframes associated with these changes.

Dispute Resolution: Include a clause for dispute resolution in the contract. This could involve arbitration, mediation, or litigation. Make sure you are comfortable with the process and that it offers a fair and reasonable way to resolve any disagreements.

Termination Clauses: Negotiate the conditions under which the contract can be terminated. This includes situations like bankruptcy, breach of contract, or if the relationship is no longer beneficial to either party.

Language and Legal Considerations: Ensure that the contract is written in a language you understand and is legally binding. Consider consulting with a legal expert to review the contract before signing.

Flexibility and Open Communication: Maintain a flexible attitude and be open to negotiation. Clear and honest communication can help both parties find a mutually beneficial agreement.

Remember, negotiation is not just about getting the best deal; it’s about building a long-term relationship that is based on trust and mutual respect. By carefully considering each term and condition, you can lay the foundation for a successful partnership with your air fryer factory supplier.

Navigating the factory floor, you can almost feel the heartbeat of the operation. The machinery hums in a rhythmic dance, each piece meticulously crafted to produce the very air fryers you’re interested in. The factory’s layout speaks volumes about its efficiency and attention to detail. Vast aisles of raw materials stretch out, neatly organized, while a sea of workers scurry about, each with a purpose and a task to complete.

You observe the assembly line, where the raw components transform into functional appliances. Workers deftly handle the parts, ensuring every connection is secure and every piece fits perfectly. You notice the quality control stations, where technicians meticulously inspect each unit for any defects or inconsistencies. The care and precision are evident in the high volume of products being processed.

As you wander through the factory, you come across areas dedicated to research and development. Engineers and designers brainstorm and prototype new features, aiming to push the boundaries of what an air fryer can do. It’s a testament to the factory’s commitment to innovation and staying ahead of market trends.

The factory’s cleanliness and organization are impressive. From the polished floors to the spotless machinery, it’s clear that hygiene and safety are top priorities. You overhear conversations about ongoing training sessions for employees, emphasizing the importance of continuous learning and upskilling.

In the warehouse, you see rows upon rows of packaged air fryers, ready to be shipped to various destinations around the world. The inventory management system is state-of-the-art, allowing for seamless tracking of stock levels and ensuring that the factory never runs out of popular models.

During your visit, you have the opportunity to meet key personnel. The factory manager is approachable and knowledgeable, eager to discuss production capabilities and the company’s vision. The sales team is adept at listening to your needs and providing solutions that align with your business goals.

You also get a glimpse into the company’s corporate social responsibility efforts. The factory has implemented energy-saving initiatives, reducing their carbon footprint and demonstrating a commitment to environmental stewardship. They also participate in local community projects, contributing to the well-being of the surrounding area.

The factory’s commitment to sustainability extends to its supply chain as well. You learn about their partnerships with suppliers who prioritize ethical practices and sustainable sourcing. This not only ensures a reliable supply of high-quality materials but also reflects the factory’s values and dedication to responsible business operations.

As the day winds down, you sit down with the factory’s legal and financial team to discuss terms. You’re presented with a detailed breakdown of costs, including the price per unit, minimum order quantities, and potential discounts for bulk purchases. You discuss payment terms, which include flexible options to suit your cash flow needs.

The logistics team walks you through their shipping processes, outlining the various transportation methods available and the associated costs. They also discuss the importance of clear communication and provide examples of their successful delivery track records.

Throughout the visit, you’ve had the chance to witness the factory’s strengths firsthand. The attention to quality, innovation, and sustainability has left a lasting impression. As you prepare to leave, you feel confident in your decision to consider this factory as a potential supplier.

The visit has been a whirlwind of information and experiences. You leave with a comprehensive understanding of the factory’s capabilities, from production to customer service. It’s a reminder that the right factory partnership can be the difference between a product that meets expectations and one that exceeds them.

Navigating the complexities of business partnerships, it’s crucial to cultivate long-term relationships with suppliers that are built on trust, mutual respect, and shared goals. Here’s how to establish such enduring connections:

Understanding the Supplier’s Vision- Look beyond the immediate transaction and consider the supplier’s long-term objectives.- Aligning with a supplier who has a vision for growth and innovation can be beneficial for your own business.- Discuss their plans for expanding their product line or entering new markets, and how this could complement your business strategy.

Communication is Key- Regular and open communication fosters a strong relationship.- Schedule regular check-ins to discuss performance, feedback, and future plans.- Use these meetings to address any concerns or issues promptly, ensuring they don’t escalate into larger problems.

Mutual Respect and Trust- Respect the supplier’s expertise and their role in the supply chain.- Trust is earned over time through consistent delivery, quality, and service.- Acknowledge the supplier’s contributions and value their input on product development and improvements.

Collaborative Problem-Solving- When challenges arise, approach them as a team rather than adversaries.- Work together to find solutions that benefit both parties.- This collaborative approach can lead to creative solutions and a deeper understanding of each other’s constraints.

Flexibility and Adaptability- Business environments are dynamic, and the ability to adapt is crucial.- Show your supplier that you’re willing to be flexible with terms or requirements when necessary.- This flexibility can lead to more creative partnerships and opportunities for mutual growth.

Investing in the Relationship- Just as you invest in your products or services, invest in your supplier relationships.- Allocate resources to support the supplier’s needs, whether it’s providing additional orders or market intelligence.- This investment can lead to loyalty and a stronger partnership.

Strategic Planning- Engage in strategic planning sessions to discuss how both businesses can support each other’s growth.- Explore opportunities for co-branding, joint marketing initiatives, or shared distribution channels.- This strategic alignment can create synergies that go beyond the immediate transactional relationship.

Feedback and Continuous Improvement- Provide constructive feedback on the supplier’s performance.- Encourage them to share their feedback with you as well.- Use this feedback loop to drive continuous improvement in the relationship.

Cultural Sensitivity- Be mindful of cultural differences and communication styles.- Celebrate cultural holidays or milestones with your supplier, fostering a sense of community and camaraderie.- This cultural sensitivity can make the relationship more enjoyable and productive.

Regular Reviews and Adjustments- Set up periodic reviews to assess the health of the relationship and make any necessary adjustments.- Be prepared to pivot or make changes as your business evolves.- This proactive approach ensures that the relationship remains dynamic and responsive to both parties’ needs.

By focusing on these aspects, you can build a long-term relationship with a supplier that is robust, resilient, and capable of adapting to the changing tides of the market. Remember, the strength of such a relationship lies in the shared understanding that both parties are working towards a common goal of success.

Navigating through the fine print, it’s crucial to ensure that every detail of the agreement is meticulously examined and understood. Begin by reviewing the contract in its entirety, paying close attention to the following key areas:

Pricing Structure: Look beyond the initial quote. Understand the pricing structure, including any discounts for bulk orders, volume-based pricing, or tiered pricing models. Clarify if there are any additional costs that might arise, such as shipping, taxes, or handling fees.

Payment Terms: Examine the payment schedule closely. Determine if there are any penalties for late payments or early settlements. Confirm the modes of payment accepted and the preferred currency, especially if dealing with international suppliers.

Delivery and Logistics: Verify the delivery timelines and methods. Ensure that the agreed-upon delivery dates are realistic and that there are clear protocols in place for any delays. Discuss the logistics of shipping, including insurance and tracking options.

Warranties and Guarantees: Check the warranty terms and guarantees provided. Understand the duration and scope of the warranty, including what is covered and what is not. Clarify the process for making warranty claims and any potential costs involved.

Intellectual Property Rights: If applicable, ensure that the agreement protects your intellectual property rights. This includes design patents, trademarks, and any proprietary information shared during the collaboration.

Termination Clauses: Read through the termination clauses carefully. Understand the conditions under which the contract can be terminated by either party and the implications of such actions.

Confidentiality and Non-Compete Agreements: Pay attention to confidentiality clauses and non-compete agreements. Ensure that they are reasonable and do not overly restrict your business operations.

Dispute Resolution: Look for a clear dispute resolution process. This might include mediation, arbitration, or litigation. Ensure that the process is fair and that the costs are clearly defined.

Force Majeure: Check for force majeure clauses that protect both parties in the event of unforeseen circumstances beyond their control, such as natural disasters or political instability.

Acceptance and Sign-off: Once you are satisfied with the agreement, ensure that all terms are acceptable to both parties. Review any changes or amendments that have been made and confirm that they are correctly reflected in the final document.

Legal Review: If possible, have the agreement reviewed by a legal professional. This can provide an additional layer of assurance that all legal aspects are covered and that the agreement is enforceable.

Language and Translation: If the agreement is in a language that is not your native tongue, ensure that it has been accurately translated. Misunderstandings can lead to costly mistakes.

Counterparty’s Commitment: Assess the commitment level of the supplier or manufacturer. Are they willing to invest in quality and service, or do they seem more focused on the sale?

Post-Sale Support: Understand the level of post-sale support offered. This includes customer service, technical assistance, and the availability of spare parts.

Feedback and Improvement: Discuss the possibility of feedback loops and continuous improvement. A good supplier will be open to suggestions and willing to make adjustments to improve the product or service.

Long-Term Vision: Consider the long-term implications of the agreement. How does this partnership align with your business goals and growth strategy?

Finalizing the Document: Once all parties are in agreement, finalize the document. Ensure that all signatures are in place and that the agreement is ready for execution.

Documentation and Record Keeping: Keep a copy of the agreement and all related documents in a secure location. This will be crucial for future reference and for any legal purposes that may arise.

By taking the time to thoroughly review and understand each aspect of the agreement, you can enter into a partnership with confidence, knowing that your interests are well-protected and that the terms are mutually beneficial.