Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

within the ecu and American kitchen appliance marketplace, as purchasers pursue both customized products and fee-effectiveness, customized touch-type oven OEM solutions have emerged as a relatively appeared progressive approach. this article will delve into how this trend is accomplishing cost reductions of up to 30% via technological innovation and strategic implementation.

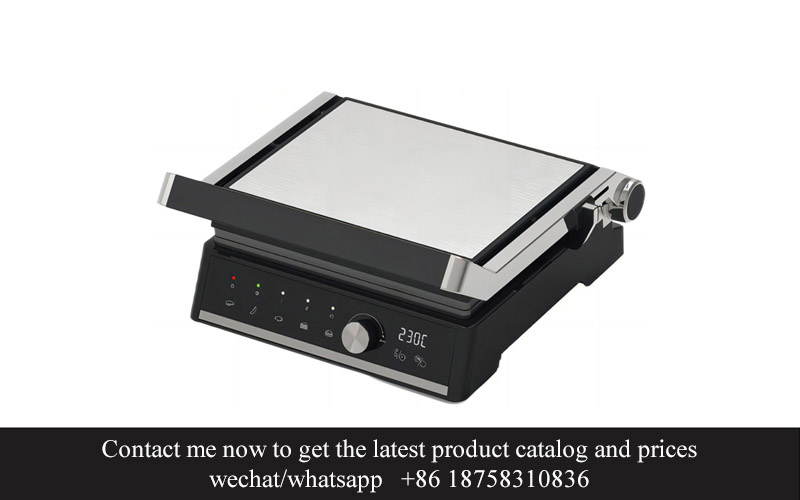

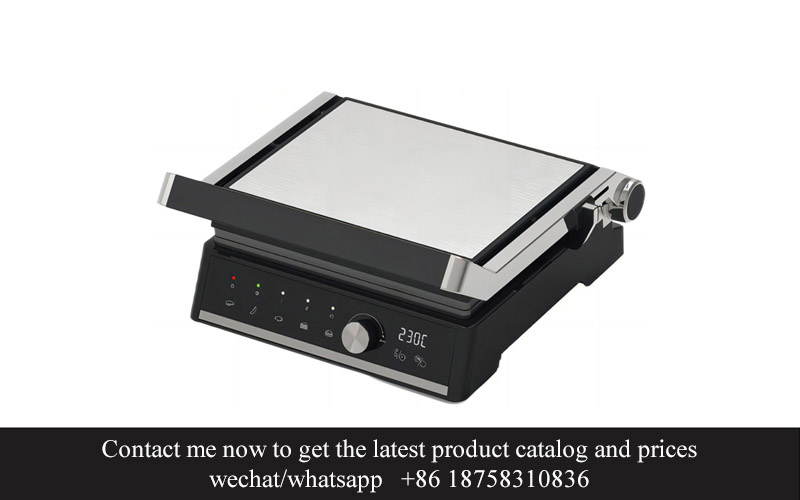

inside the current kitchen appliance market, OEM (unique system manufacturer) services for custom designed contact grills have emerged as a brand new and especially sought-after path. This provider no longer handiest satisfies consumers’ pursuit of customization and diverse functionalities, however also brings considerable price advantages to the companies.

custom designed contact grill OEM offerings allow producers to layout and produce merchandise based at the specific desires in their customers. This bendy manufacturing model method that organisations can speedy regulate product configurations in reaction to market comments and patron choices, thereby meeting ever-changing market needs. In phrases of costs, OEM offerings can assist companies gain powerful cost reductions at the same time as making sure product excellent thru optimized supply chain management and manufacturing strategies.

custom designed manufacturing reduces unnecessary inventory accumulation. conventional grill manufacturing often requires big amounts of stock to deal with market demand uncertainty, whilst OEM offerings can produce based totally on the quantity of orders, hence lowering inventory costs. moreover, custom designed design enhances cloth utilization. conventional grills may additionally waste materials because of standardized designs, whereas OEM services can precisely control material usage primarily based on product specifications, thereby lowering uncooked fabric prices. in the end, OEM providers frequently experience economies of scale, which allows them to lower the manufacturing cost per unit through bulk procurement.

Technological innovation is a key component in price reduction. With the application of sensible and automatic technologies, the production efficiency of o.e.m grills has notably stepped forward. for instance, the adoption of advanced slicing strategies and automatic assembly strains now not most effective increases manufacturing velocity however also reduces greater expenses due to human mistakes. on the same time, wise gadget can display the production method in actual-time, making sure product first-class at the same time as lowering waste as a result of faulty products.

it’s also noteworthy that custom designed contact grill OEM services decorate product competitiveness even as decreasing costs. by using providing grills that higher align with purchasers’ personalized desires, firms can gain a positive role in excessive market opposition. as an instance, some businesses have added designs with distinctive temperature manage zones through OEM services, assembly purchasers’ particular temperature manipulate requirements throughout cooking.

In precis, custom designed touch grill OEM offerings provide organisations with a brand new direction to reduce charges. via flexible customized production, technological innovation, and economies of scale, organisations can hold product satisfactory while improving market competitiveness, achieving sustainable development.

With the fluctuations of the global economy and adjustments in patron shopping power, the kitchen home equipment market is undergoing profound shifts in market traits. purchasers’ growing pursuit of price for money immediately affects the design and production of kitchen appliance products. here is an in depth analysis of this trend:

fee manipulate as a Key aggressive aspect: within the kitchen equipment industry, mainly for products like contact-kind grills, price control has grow to be a critical element for keeping competitiveness. With fluctuations in uncooked material costs and growing exertions fees, businesses are forced to seek new avenues for price discount.

purchaser awareness on value for money: whilst purchasing kitchen appliances, consumers not entirely cognizance on brand and capability; rather, they area extra emphasis on the product’s cost for money. This trend is forcing manufacturers to searching for greater price-powerful production methods at the same time as making sure product high-quality.

three. Technological Innovation Drives fee Optimization: to fulfill consumers’ fee-sensitive needs, kitchen appliance producers are making an investment in technological innovation. by using enhancing production tactics, optimizing product designs, and the use of more efficient materials, manufacturers can lessen charges with out compromising performance.

five. supply Chain Integration Reduces fees: thru supply chain integration, kitchen equipment producers can reduce intermediary links, slicing logistics and stock fees. moreover, organising long-term partnerships with providers can assist cozy greater favorable procurement prices.

power performance and Environmental safety as New standards: In a value-sensitive marketplace environment, power efficiency and environmental protection have turn out to be new requirements for kitchen appliance merchandise. by using growing energy-saving technology, manufacturers can’t handiest lessen the operational fees of products but also beautify their market competitiveness.

data analysis Assists selection-Making: To greater as it should be draw close market dynamics and patron desires, kitchen equipment manufacturers are an increasing number of relying on facts analysis. by means of studying marketplace trends and consumer conduct, organizations can greater successfully formulate fee control strategies.

In summary, the fee sensitivity inside the kitchen home equipment marketplace is using non-stop innovation via corporations. thru efforts in technological innovation, custom designed offerings, deliver chain integration, strength performance and environmental safety, and statistics evaluation, kitchen appliance producers are striving to keep product great at the same time as accomplishing sizeable fee discounts.

The kitchen equipment enterprise has constantly targeted on fee manage. In latest years, with the growing demand for personalization from customers, custom designed contact grill OEMs have turn out to be a brand new favourite in the marketplace. the following is a case have a look at on how to attain a 30% cost reduction thru technological innovation and strategies underneath this trend.

Modular layout Optimizes production processModular design performs a vital position in the manufacturing of custom designed grills. by means of decomposing the grill into numerous interchangeable modules, organizations can fast modify production to satisfy consumer wishes, decreasing stock buildup. This layout simplifies production complexity, improves efficiency, and for that reason reduces production prices.

smart production enhances efficiency and Lowers power consumptionThe advent of sensible production systems, along with automatic welding, reducing, and assembly system, not best increases production velocity but additionally reduces labor prices. moreover, thru clever tracking systems, the power consumption of the production line is actual-time monitored and optimized, similarly reducing running fees.

three. supply Chain Integration Lowers Procurement chargesthrough integrating the deliver chain, groups can establish lengthy-time period and stable relationships with providers, securing more favorable uncooked fabric procurement charges. on the equal time, the centralized procurement method reduces logistics charges and improves procurement efficiency. within the case take a look at, the uncooked fabric cost of the grill became decreased by way of about 15% via optimized deliver chain control.

five. exceptional control Improves Operational efficiencyIn phrases of operational management, the organization has carried out a exceptional control method. with the aid of undertaking targeted analysis of every aspect of the production process, waste is recognized and eliminated, accomplishing most beneficial aid allocation. for instance, through optimizing manufacturing plans, the waiting time within the production system is decreased, improving typical manufacturing performance.

through the implementation of the aforementioned technological innovations and techniques, the agency successfully completed a 30% value discount within the customized touch grill OEM product. This no longer handiest superior the organisation’s marketplace competitiveness however additionally set an instance of value manipulate for the industry.