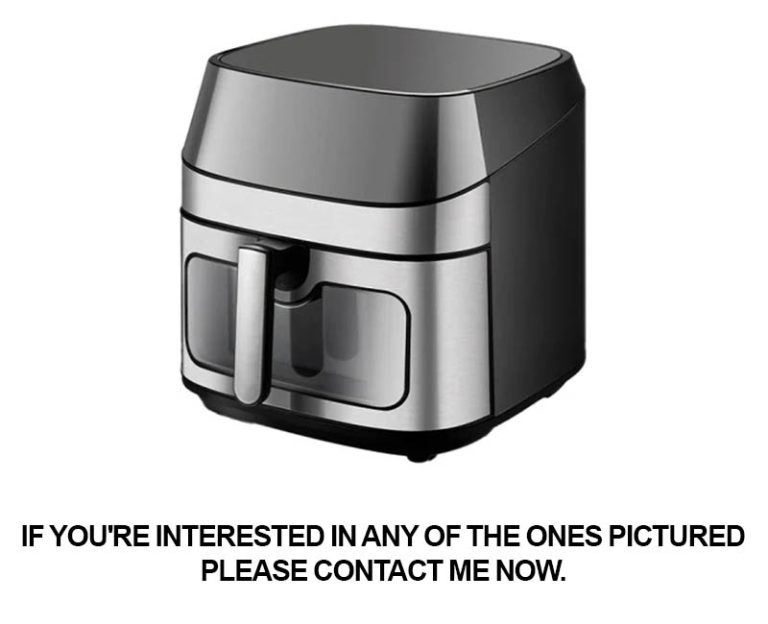

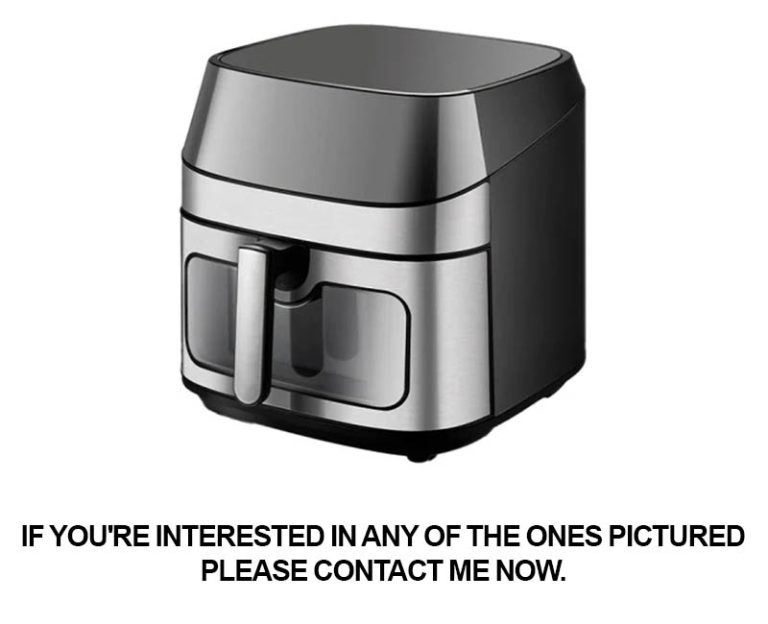

The NSF Certified 1800W Air Fryer has revolutionized cooking with its health-forward approach. This versatile appliance reduces oil usage by up to 80%, offering a guilt-free alternative to traditional frying. Its high power rating ensures even cooking, while the digital controls and non-stick interior enhance convenience and ease. The air fryer’s ability to bake, roast, and even dehydrate extends its utility, making it a staple for health-conscious cooks seeking efficient and delicious meals. With its NSF certification, users can trust its safety and performance, making it an essential kitchen appliance for those aiming to improve their diet and cooking habits.

In the dynamic world of kitchen appliances, the rise of ETL listed commercial units marks a significant shift towards safety, efficiency, and innovation. These appliances, certified by the Electrical Testing Laboratories, are not just tools for cooking but integral companions in modern kitchens. Their precision, consistency, and health-conscious features, like sous-vide cooking and high-pressure pasteurization, cater to today’s culinary trends. The integration of smart technology allows for remote control and monitoring, enhancing operational efficiency. With a focus on sustainability, these units are eco-friendly, featuring energy-saving modes and recyclable materials. The evolution of kitchen appliances reflects a commitment to quality, safety, and the ever-growing demand for diverse and versatile cooking solutions.

In the heart of China’s Zhejiang province, Ningbo has emerged as a leading FOB Ningbo air fryer supplier, revolutionizing cooking with its innovative and health-conscious appliances. These air fryers, known for their minimal oil usage and versatile cooking capabilities, have soared in popularity in Europe and the US. Ningbo’s manufacturers, leveraging the city’s strategic location and robust manufacturing ecosystem, produce air fryers that blend efficiency, style, and cutting-edge technology. From compact countertop models to large commercial units, Ningbo’s air fryers cater to diverse needs, solidifying its status as a top supplier in the global kitchen appliance market.

In the realm of kitchen appliances, the CE-EMC compliant 2200W category is leading the charge in cooking innovation. These powerful yet energy-efficient devices are reshaping culinary experiences with their seamless integration of smart technology, safety standards, and multi-functional capabilities. As the heart of modern kitchens, these 2200W appliances are not just tools for cooking—they are companions that enhance efficiency, safety, and the overall joy of preparing meals. The rise of these appliances reflects a market shift towards high-performance, smart kitchen solutions that cater to both the efficiency-conscious and the tech-savvy consumer.

The Moscow air fryer manufacturer has become a leader in the culinary appliance industry with its innovative air fryers. These advanced cooking devices have surged in popularity due to their health-conscious cooking capabilities, using minimal oil to achieve crispiness. The manufacturer’s commitment to sustainability, smart technology integration, and user-friendly design has positioned it at the forefront of the market. By focusing on energy efficiency and health benefits, this company is redefining the way consumers approach cooking with their air fryer appliances.

In the realm of commercial air fryer technology, our factory stands out as a beacon of innovation. Specializing in the production of high-quality air fryers, we are at the forefront of this health-conscious cooking revolution. Our air fryers offer a healthier, more efficient alternative to traditional frying methods, reducing oil usage and cutting down on cooking time. With a focus on cutting-edge technology and user-friendly designs, our air fryers are versatile enough to cater to a wide range of cooking needs. As a leading commercial air fryer factory, we continuously push the boundaries of what air fryers can achieve, ensuring that our products not only meet but exceed industry standards and customer expectations.

The rise of the restaurant-grade air fryer factory signifies a culinary revolution, transforming the home kitchen with a game-changing appliance. These advanced air fryers bridge the gap between professional cooking and domestic convenience, offering a healthier, versatile alternative to traditional frying. As a staple in modern cooking, air fryers are redefining the way we prepare and enjoy our meals, making cooking more efficient and enjoyable.

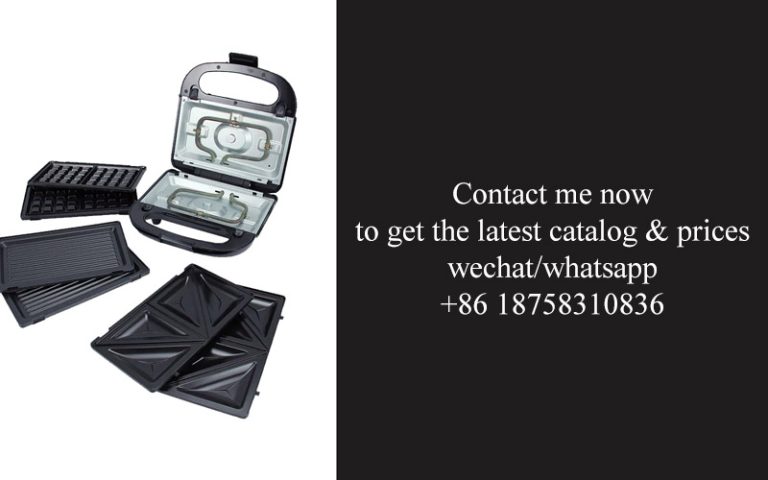

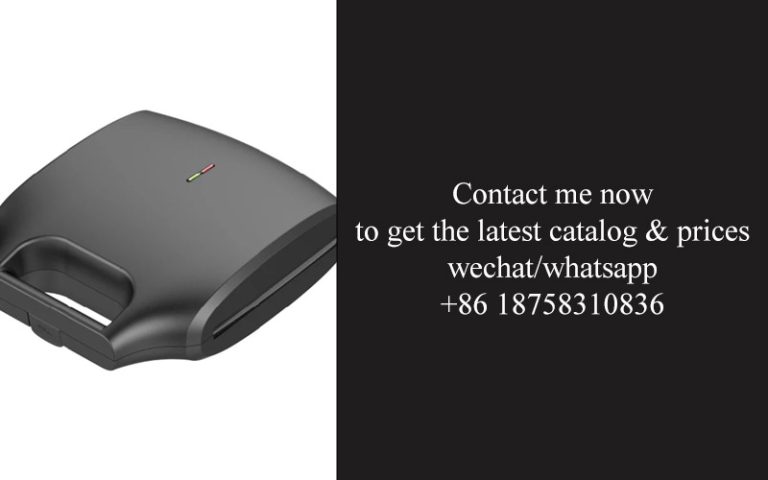

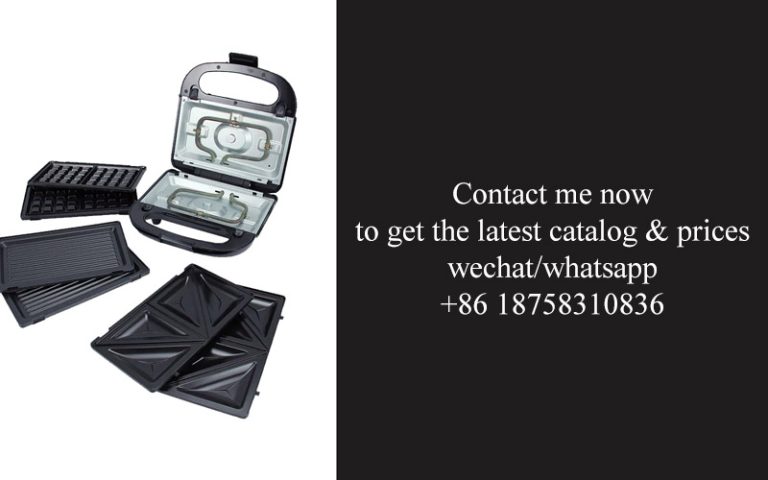

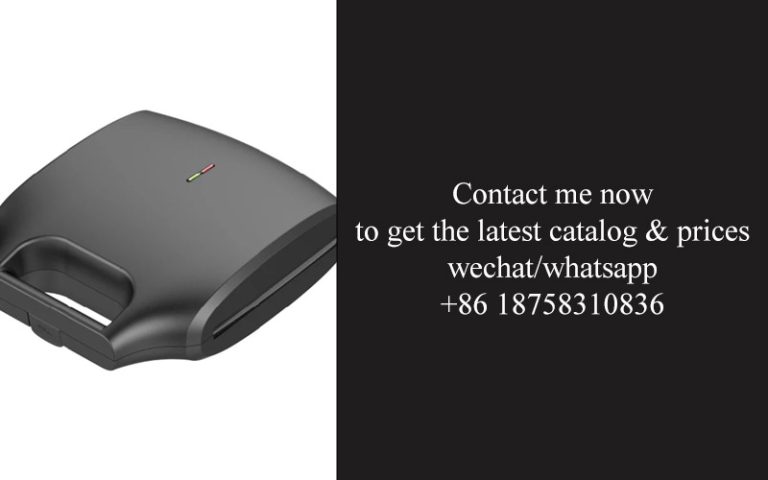

The rise of the heavy duty sandwich press has transformed the kitchen appliance market, with innovative features driving its popularity. These robust presses, produced by dedicated heavy duty sandwich press factories, offer a blend of convenience and cooking versatility. With features like adjustable heat settings, non-stick surfaces, and durable construction, they ensure perfect, golden-brown sandwiches every time. Their sleek designs and user-friendly controls make them a must-have for modern kitchens, where quick, healthy meals are in demand. These factories prioritize quality and innovation, crafting appliances that cater to the evolving tastes and needs of consumers, making the heavy duty sandwich press an indispensable tool for any culinary enthusiast.

The continuous operation sandwich grill plant has emerged as a revolutionary force in the food service industry, offering unparalleled efficiency and speed in cooking. These innovative facilities leverage cutting-edge technology to ensure precise and consistent sandwich production, often with capabilities to cook hundreds of sandwiches per hour. The integration of automated systems and advanced cooking technology not only guarantees high-quality output but also significantly reduces wait times for customers. This shift marks a significant advancement in the culinary landscape, promising a future where food preparation is optimized for both speed and quality.

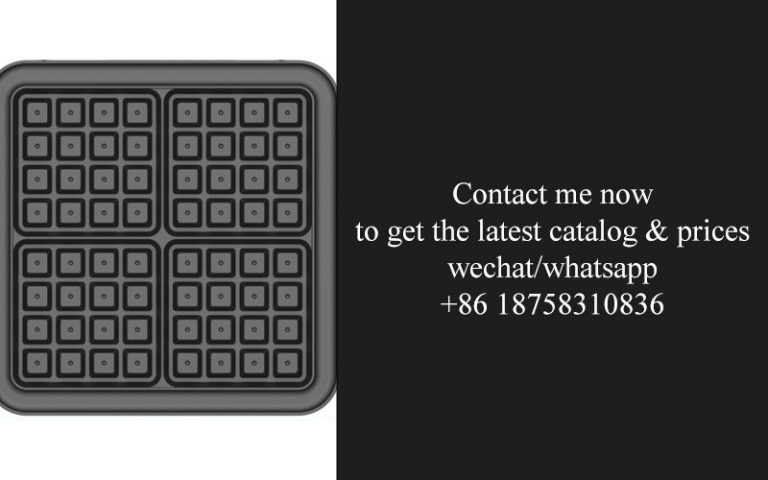

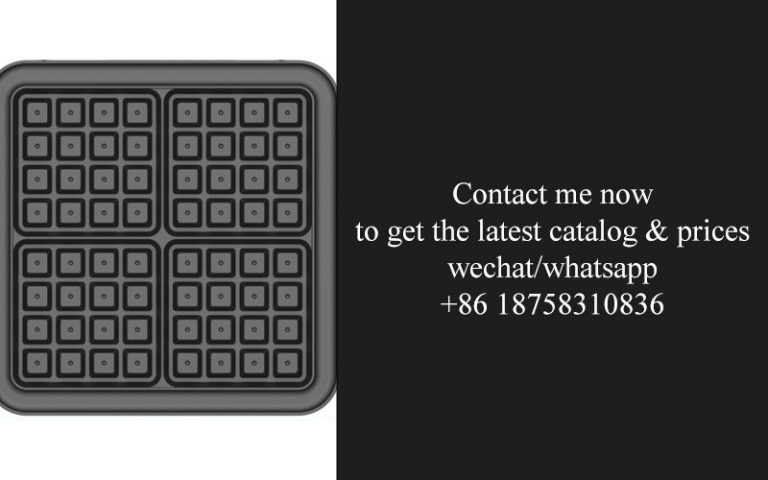

In the realm of kitchen appliances, integrated metal stamping has revolutionized the design and functionality of sandwich plates. This advanced manufacturing technique, known for its precision and efficiency, has enabled the creation of durable, heat-resistant, and aesthetically pleasing sandwich plates. These innovative cooking tools not only enhance the cooking experience with their versatility but also seamlessly integrate into modern kitchen aesthetics. As the demand for efficient and high-quality kitchenware grows, integrated metal stamping continues to play a pivotal role in shaping the future of cooking appliances.