The Arctic Grade Waffle Maker has emerged as a groundbreaking equipment for excessive bloodless environments, supplying sturdiness and advanced baking capabilities in frigid temperatures. Engineered with cold-resistant materials and modern heating technology, this waffle maker guarantees even warmness distribution and maintains overall performance in sub-0 situations, making it an crucial for households and adventurers alike in cold climates. Its design prioritizes user-friendliness and protection, while its robust production ensures lengthy-lasting use, solidifying its position as a must-have in the baking market for polar cities.

within the dynamic kitchen equipment marketplace, OEM producers are dealing with unheard of possibilities and challenges. As purchaser needs evolve toward customization and intelligence, these manufacturers are striving to innovate and differentiate themselves. they may be integrating clever era, offering personalised product lines, and specializing in consumer enjoy to satisfy the developing call for for smart kitchen home equipment. marketplace traits show a shift in the direction of specialization and move-enterprise integration, with manufacturers investing in R&D and intellectual belongings safety to keep their competitive side. This power for differentiation is shaping a extra intelligent and user-centric kitchen appliance enterprise.

under the wave of globalization, the economic waffle maker enterprise is undergoing a notable transformation. producers in towns like positive aren’t best tasked with catering to numerous culinary needs however also are using technological innovation and production improvements. those factories are at the forefront, ensuring product quality, fitness safety, and environmental sustainability. With a focus on technology, producers are integrating smart capabilities, automation, and IoT into their manufacturing procedures, presenting a range of waffle makers from manual to automatic. The industry is poised for growth, pushed by using market demands for multifunctional, fitness-aware, and custom-designed waffle makers, all while embracing the ultra-modern technological advancements.

Ningbo’s kitchen appliance dealer is a leading participant within the enterprise, attaining a monthly manufacturing capacity of 10,000 units. With a eager market belief and modern design, this Ningbo small equipment provider has carved out a gap by optimizing production methods, ensuring inexperienced and green production. The company invests in superior generation, from computerized manufacturing traces to smart manage systems, and gives customizable products to cater to diverse purchaser desires. Their dedication to satisfactory, product innovation, and market trends has propelled them to huge success in both home and worldwide markets, solidifying their position as a key player within the kitchen appliance area.

The East China OEM production facility is rising as a sizable participant within the ecu and American kitchen equipment market, imparting unique customization with a bendy MOQ of 500 devices. Its strategic location in China, comprehensive industrial chain, and technological innovation permit it to produce , value-powerful appliances that cater to the precise options of eu and American clients. by specializing in marketplace adaptability, strict excellent manipulate, and innovative carrier offerings, the East China OEM factory is driving the market’s increase and innovation in kitchen home equipment.

The CE-certified air fryer OEM marketplace is experiencing full-size growth because of the surge in fitness-conscious dwelling. Air fryers, with their low-fat cooking functions, have gained tremendous recognition. CE-certified air fryers, adhering to stringent safety requirements, are main the fashion. those home equipment now not most effective provide health benefits however additionally include clever technology, like contact interfaces and multifunctional cooking modes. The market is expanding with numerous product strains, concentrated on various patron needs, and leveraging worldwide market possibilities. no matter challenges like growing raw fabric costs and environmental regulations, the enterprise’s boom potential stays robust, pushed via technological innovation and consumer demand for more healthy cooking alternatives.

The EAC-compliant sandwich maker manufacturing facility holds enormous advantages within the market. Its certification guarantees adherence to rigorous Russian requirements, vital for getting into the Russian market and ensuring product excellent and safety. This compliance boosts the manufacturing facility’s competitiveness, as EAC certification signifies reliability and excellent, enhancing its logo picture. through smart manufacturing enhancements, environmental design, consumer customization, sturdy brand building, and non-stop R&D, the manufacturing unit leverages these advantages to face out in the sandwich maker industry. Strict high-quality manage maintains product safety, reinforcing its aggressive area and securing its position as a key player inside the marketplace.

The low MOQ air fryer market is thriving, driven by means of a surge in demand for healthy cooking solutions. producers are capitalizing on this fashion by means of presenting flexible manufacturing and progressive designs, integrating smart generation and

materials. as the air fryer marketplace expands, possibilities for low MOQ manufacturers consist of quick market response, deliver chain agility, and logo differentiation. searching ahead, technological innovation, fitness and environmental attention, and pass-industry collaboration might be key to destiny boom and achievement within the aggressive air fryer marketplace.

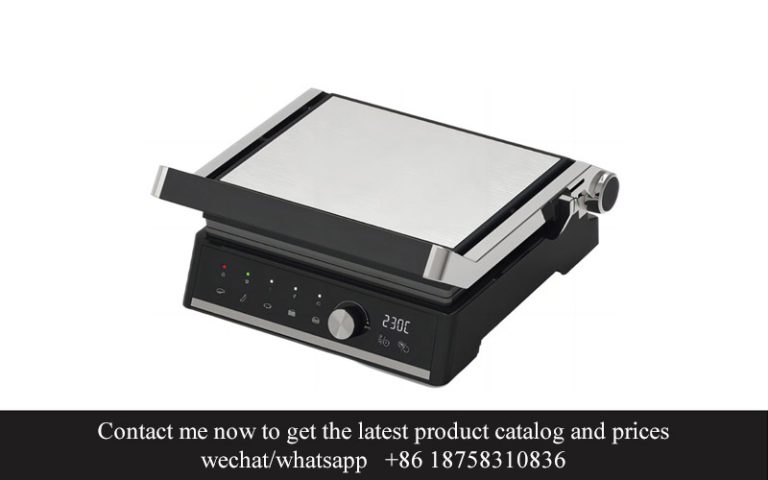

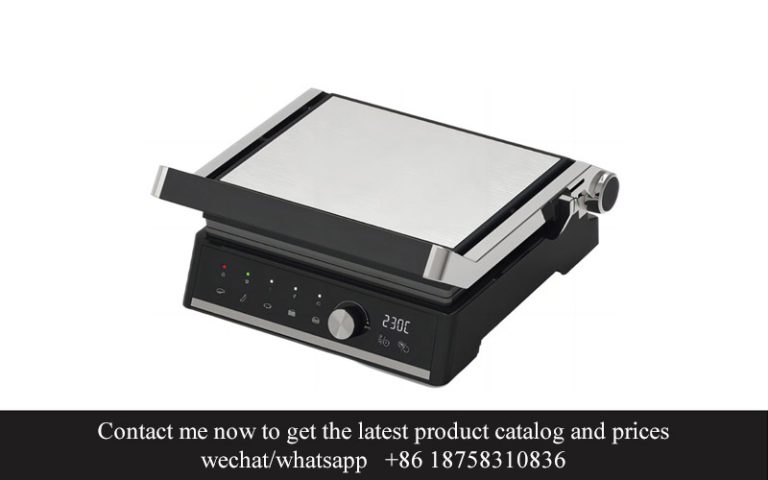

inside the equipment marketplace, customizable touch grill OEM answers have emerged as a key approach for producers searching for up to a 30% value reduction. by using leveraging modular layout, smart manufacturing structures, and deliver chain integration, corporations optimize manufacturing strategies, decorate efficiency, and reduce procurement costs. moreover, R&D investments in center technology and a focus on fine control further streamline operations, enabling manufacturers to deliver

grills at a aggressive charge, thereby strengthening their marketplace function.

inside the kitchen appliance industry, high-quantity juicer production traces are essential for efficiency and marketplace responsiveness. these traces, with their superior automation and modular layout, enhance production velocity and flexibility, ensuring speedy reaction to customer desires. enforcing a forty eight-hour brief quoting device similarly boosts patron revel in with the aid of expediting decision cycles and presenting particular, personalised provider. records-pushed innovation is shaping the destiny of kitchen home equipment, with a focus on intelligent interaction, health-conscious features, and personalised cooking solutions, all even as emphasizing environmental sustainability. This approach allows kitchen appliance organizations in towns to cater to the evolving needs of customers and preserve a aggressive area within the cooking market.