Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

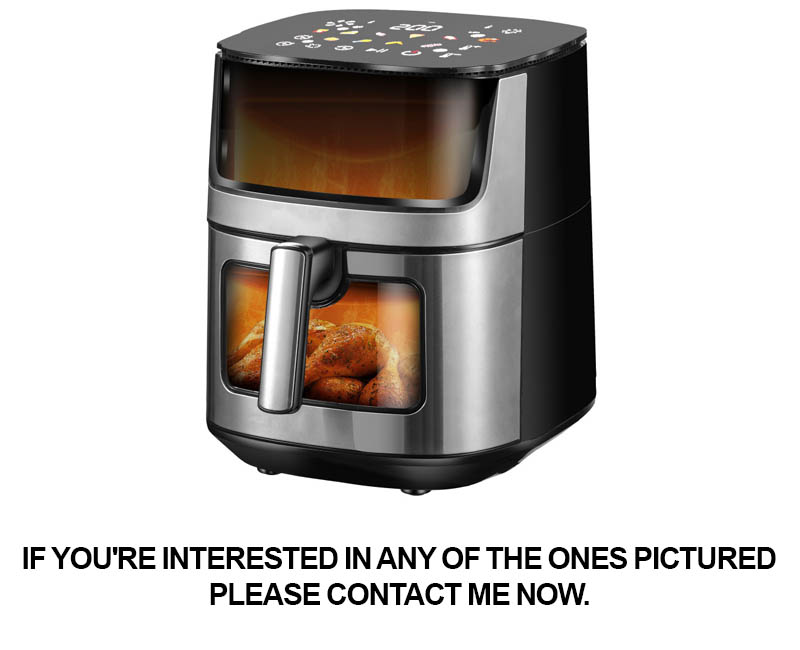

As the culinary landscape continues to evolve, the air fryer has emerged as a beacon of innovation in the kitchen appliances sector. Its ability to offer a healthier cooking alternative without sacrificing flavor has captured the imagination of consumers worldwide. Today, we delve into the transformative journey of the air fryer, exploring its impact, the advancements in its assembly line process, and the promising future it holds for the industry.

The landscape of kitchen appliances has undergone a remarkable transformation with the rise of automated technology. From the early days of mechanical mixers to the sleek, smart ovens of today, the integration of automation has redefined the way we interact with our kitchen tools. This evolution has been driven by a combination of consumer expectations, technological advancements, and the quest for efficiency.

In the past, kitchen appliances were often large, bulky, and required a considerable amount of manual labor to operate. However, the advent of microprocessors and robotics has allowed for the creation of appliances that are not only more intuitive but also capable of performing complex tasks with precision. The rise of automated technology in kitchen appliances can be attributed to several key factors.

Firstly, the demand for convenience has surged as modern lifestyles become increasingly fast-paced. Consumers no longer have the luxury of spending hours preparing meals. Instead, they seek appliances that can simplify cooking processes, from pre-programmed settings to hands-free operation. Automated technology has made it possible for appliances to cater to these needs, ensuring that even the busiest individuals can enjoy home-cooked meals with minimal effort.

Secondly, the emphasis on health and wellness has prompted the development of innovative cooking methods. Air fryers, for instance, have gained popularity due to their ability to mimic deep-frying with less oil, thus reducing the calorie content of foods. The automation of these appliances ensures that the cooking process is consistent and efficient, making healthy eating more accessible to a wider audience.

Moreover, the integration of the Internet of Things (IoT) has opened up new possibilities for kitchen appliances. Smart appliances can now be connected to smartphones or home assistants, allowing users to control them remotely. This connectivity not only enhances the user experience but also enables data collection and analysis, which can lead to more personalized and efficient appliance design.

The manufacturing process of kitchen appliances has also been revolutionized by automation. Assembly lines are now equipped with robotic arms and automated systems that can perform tasks such as soldering, welding, and even painting with unparalleled accuracy. This shift has not only increased production speed but has also reduced the likelihood of errors, leading to higher quality products.

Another significant aspect of the rise of automated technology in kitchen appliances is the reduction in waste. Automated systems can optimize material usage, minimize scrap, and even predict maintenance needs, thereby extending the lifespan of appliances and reducing environmental impact.

The benefits of automated technology are not limited to manufacturers and consumers. Retailers have also seen advantages, as automated systems can streamline inventory management and improve supply chain efficiency. This has led to better product availability and more informed purchasing decisions.

In the realm of innovation, the rise of automated technology has spurred the creation of entirely new categories of kitchen appliances. For example, 3D printing has enabled the production of customized cookware and kitchen utensils, catering to the unique needs and preferences of individual users.

Despite the numerous benefits, the adoption of automated technology in kitchen appliances has not been without its challenges. The initial cost of implementing such systems can be substantial, and there is often a learning curve for employees who must adapt to new machinery. Additionally, there are concerns about job displacement as automation takes over tasks that were once performed by humans.

In conclusion, the rise of automated technology in kitchen appliances is a testament to human ingenuity and the relentless pursuit of efficiency. It has transformed the way we cook, eat, and interact with our kitchen tools, promising a future where convenience, health, and sustainability go hand in hand. As technology continues to advance, it’s clear that the kitchen of tomorrow will be a place where innovation is not just a buzzword but a way of life.

The air fryer has emerged as a game-changer in the world of healthy cooking, reshaping the way we approach our meals and our health. Once a niche device, it has now become a staple in many kitchens, offering a healthier alternative to traditional frying methods.

Once confined to the realm of deep-fat fryers, the air fryer uses a process that involves circulating hot air around food to achieve a crispy texture without the need for excessive oil. This technological leap has not only reduced the calorie content of fried foods but has also made them more accessible to those with dietary restrictions or health concerns.

The concept of the air fryer is simple yet revolutionary. By utilizing rapid air circulation, the appliance can cook a variety of foods, from crispy French fries to golden-brown chicken tenders, all while retaining more of the nutrients compared to traditional frying. This has been a significant shift for health-conscious consumers who have long been wary of the health impacts of deep-fat frying.

One of the key reasons for the air fryer’s surge in popularity is its versatility. It can handle a wide range of recipes, from appetizers to desserts, making it a versatile tool in the kitchen. Whether you’re looking to make a batch of crispy onion rings or a batch of homemade potato chips, the air fryer can do it all with minimal oil.

Moreover, the air fryer’s health benefits are not just about reducing calories. It also lowers the risk of heart disease and other health issues associated with excessive oil consumption. The device’s ability to cook food at lower temperatures compared to traditional frying methods also preserves more of the natural flavors and vitamins, enhancing the overall taste and nutritional value of the meal.

The convenience factor cannot be overlooked. Air fryers are compact and easy to use, making them a perfect addition to any kitchen. They save time and effort, as you can simply place your ingredients inside and walk away. The cleanup is also a breeze, as there’s often less oil involved, which means fewer greasy dishes to wash.

As the air fryer has gained traction, it has also spurred innovation in the kitchen appliance industry. Manufacturers are now introducing smart features, such as digital timers, temperature controls, and even recipe suggestions, to make the cooking process even more intuitive and enjoyable.

The air fryer has also had a positive impact on the way we think about cooking. It encourages experimentation and creativity in the kitchen, as users can try out a variety of recipes that they might not have considered before. This democratization of cooking has made it easier for home chefs to explore new flavors and techniques without the need for complex or expensive equipment.

Furthermore, the air fryer’s rise has been a boon for the environment. By reducing the amount of oil used in cooking, it helps to minimize waste and the environmental impact associated with disposing of used cooking oil. This eco-friendly aspect has made the air fryer an even more attractive option for environmentally conscious consumers.

In conclusion, the air fryer has redefined healthy cooking by offering a method that is both delicious and nutritious. Its convenience, versatility, and health benefits have made it a must-have appliance for anyone looking to improve their diet and cooking habits. As the technology continues to evolve, we can expect even more innovative features and recipes that will further solidify the air fryer’s status as a game-changer in the world of kitchen appliances.

The Air Fryer: A Game-Changer in Healthy Cooking

In recent years, the kitchen appliance market has witnessed a significant shift towards healthier cooking methods. Among these innovations, the air fryer has emerged as a true game-changer, offering a guilt-free alternative to traditional frying. This compact appliance has not only transformed the way we cook but has also revolutionized the food industry’s approach to health and convenience.

The allure of the air fryer lies in its ability to mimic the crispy texture of fried foods without the need for excessive oil. By circulating hot air around the food, the appliance achieves a golden-brown finish, reducing the fat content by up to 80% compared to traditional deep-frying. This breakthrough in cooking technology has piqued the interest of health-conscious consumers who are looking for ways to indulge in their favorite fried treats without compromising their diet.

As people become more aware of the health risks associated with excessive oil consumption, such as heart disease and obesity, the air fryer has become a beacon of hope. It allows for the preparation of a wide range of dishes, from crispy French fries and chicken wings to even desserts like beignets and doughnuts. The versatility of the air fryer has made it a staple in many households, encouraging a healthier lifestyle without sacrificing flavor.

The need for an Automated Air Fryer Assembly Line

With the growing popularity of air fryers, the demand for these appliances has surged. To meet this demand, manufacturers are increasingly turning to automation. An automated air fryer assembly line is not just a response to market trends; it’s a necessity for several reasons.

Efficiency is paramount in today’s fast-paced world, and an automated assembly line can significantly enhance productivity. The line can operate 24⁄7 without breaks, ensuring a constant flow of air fryers ready for distribution. This around-the-clock operation not only reduces lead times but also minimizes the risk of production bottlenecks that can occur in traditional manufacturing setups.

Quality control is another critical aspect of manufacturing. An automated assembly line can incorporate advanced sensors and cameras to monitor the assembly process, ensuring that each air fryer meets stringent quality standards. This level of precision is difficult to achieve with manual labor alone, as human error can lead to inconsistencies in the final product.

Furthermore, the labor-intensive nature of assembling air fryers can be a drain on resources. An automated line reduces the need for a large workforce, which in turn lowers labor costs and minimizes the risk of workplace accidents. The machinery can perform repetitive tasks with precision, freeing up human workers to focus on more complex and creative aspects of the manufacturing process.

Customization is also a key factor in the appliance market. An automated assembly line can be programmed to accommodate various models and configurations of air fryers, allowing manufacturers to quickly adapt to changing consumer preferences. This flexibility is essential in a market where innovation is key to staying competitive.

Innovation and Sustainability

The shift towards automation in the air fryer assembly process is not just about efficiency and cost savings; it’s also about fostering innovation and sustainability. As technology advances, manufacturers can incorporate new features into their air fryers, such as smart controls and energy-saving modes. An automated line can be easily updated to include these enhancements, ensuring that the latest technological advancements are quickly integrated into the production process.

Moreover, sustainability is a growing concern for consumers and businesses alike. An automated assembly line can be designed with energy-efficient machinery and waste-reducing processes, contributing to a greener manufacturing footprint. By minimizing waste and reducing energy consumption, manufacturers can not only appeal to environmentally conscious customers but also reduce their environmental impact.

In conclusion, the need for an automated air fryer assembly line is a direct response to the market’s demand for efficient, high-quality, and sustainable kitchen appliances. As the air fryer continues to gain popularity, the industry must evolve to meet these demands, ensuring that this game-changing appliance remains accessible and beneficial to consumers worldwide.

The air fryer, once a niche gadget, has now become a staple in many modern kitchens. Its ability to mimic the crispy texture of fried foods without the high fat content has revolutionized the way we cook. As the popularity of air fryers continues to soar, the need for an automated assembly line becomes increasingly evident.

The traditional assembly of air fryers involves numerous manual steps, each requiring skilled labor. However, with the increasing demand for these appliances, manual assembly is no longer efficient or cost-effective. An automated assembly line addresses this challenge by integrating a series of precision machines that work together to produce air fryers at a much faster rate.

In the automated assembly line, every component of the air fryer is meticulously handled. From the metal sheets that form the outer shell to the intricate electrical components, each part is placed with extreme precision. Advanced robotics and automated machinery ensure that every air fryer that rolls off the line meets the same high-quality standards.

One of the key advantages of an automated assembly line is the seamless integration of quality control measures. As the air fryer moves through the line, it undergoes a series of checks and tests. These include visual inspections, functional tests, and safety checks to ensure that the product is free from defects and ready for the consumer.

Automation has significantly boosted the efficiency of the assembly process. Tasks that once took hours to complete can now be done in mere minutes. This not only reduces production time but also minimizes the risk of human error. The result is a streamlined operation that can handle large volumes of air fryers without compromising on quality.

The beauty of an automated assembly line lies in its flexibility and scalability. As the market demand for air fryers fluctuates, the line can be easily reconfigured to accommodate different models or to increase production capacity. This adaptability ensures that manufacturers can keep up with the ever-changing consumer preferences and market trends.

The assembly line is not just about automating the existing process; it’s also about integrating new technologies. For instance, the use of 3D printing for custom parts, advanced sensors for real-time monitoring, and predictive maintenance software to prevent downtime are all becoming part of the modern assembly line landscape.

An automated assembly line is also designed with energy efficiency and resource conservation in mind. By reducing the need for manual labor and optimizing the use of materials, manufacturers can lower their carbon footprint and contribute to a more sustainable production process.

With the introduction of an automated assembly line, there is a need for ongoing training and development for the workforce. Employees must be upskilled to work alongside robots and understand the new technologies that are integrated into the line. This ensures that the human element remains a valuable part of the production process.

The rise of the air fryer as a game-changer in healthy cooking has brought with it a new set of challenges for manufacturers. The need for an automated assembly line is not just a response to market demand but a strategic move to ensure that air fryers continue to be produced with precision, efficiency, and sustainability. As the industry evolves, the assembly line will undoubtedly play a pivotal role in shaping the future of kitchen appliances.

In today’s fast-paced world, efficiency and precision are paramount, especially in the production of consumer goods. The rise of the automated air fryer assembly line is a testament to this demand for excellence. Here are some of the key benefits that this innovative approach brings to the table.

Efficiency in MotionThe automation of the assembly line process significantly speeds up the production of air fryers. By eliminating manual labor, each step from component insertion to final quality checks can be completed in a fraction of the time it would take with human hands. This not only boosts productivity but also ensures that the assembly line can run 24⁄7 without the need for breaks, maximizing output.

Precision EngineeringIn the realm of air fryer assembly, precision is critical. Automated systems are designed to maintain consistent standards in every aspect of the manufacturing process. From the precise alignment of components to the uniform application of heat and pressure, the automated assembly line ensures that every air fryer meets or exceeds quality expectations.

Quality Control ReinventedWith a manual assembly line, the risk of human error is ever-present. However, an automated assembly line incorporates advanced quality control measures. Sensors and cameras are used to monitor the production process, detecting any deviations from the standard. This real-time monitoring ensures that defective products are identified and removed before they reach the end of the line.

Cost-Effective SolutionsWhile the initial investment in an automated assembly line can be substantial, the long-term financial benefits are substantial. Reduced labor costs, minimized waste, and the ability to produce more units in less time all contribute to a more cost-effective operation. Additionally, with lower error rates, the need for returns and repairs is significantly diminished, further cutting costs.

Scalability for GrowthAs consumer demand for air fryers continues to soar, manufacturers need to be ready to scale up production quickly. An automated assembly line is inherently scalable, allowing for easy adjustments to meet increased production needs. This flexibility is a game-changer for businesses looking to capitalize on market trends and consumer preferences.

Sustainability at ScaleThe environmental impact of manufacturing is a growing concern. Automated assembly lines are designed with sustainability in mind. By reducing energy consumption and waste, these lines contribute to a greener manufacturing process. This not only aligns with corporate social responsibility goals but also appeals to eco-conscious consumers.

Workforce TransformationThe shift to an automated assembly line doesn’t spell the end for human workers; instead, it transforms the role they play in the manufacturing process. Workers can be retrained to oversee and maintain the automated systems, ensuring they continue to be an integral part of the production process. This shift allows for a more skilled workforce, capable of managing complex machinery and ensuring smooth operations.

Customer Satisfaction and TrustA product that is consistently high in quality and reliability fosters customer satisfaction and trust. With an automated assembly line, manufacturers can guarantee that each air fryer meets the same stringent quality standards. This consistency is crucial in building a brand reputation that stands the test of time.

The automation of the air fryer assembly line is more than just a technological advancement; it’s a leap forward in how we approach manufacturing. From efficiency and precision to cost savings and scalability, the benefits are clear. As the market for air fryers continues to grow, embracing this automated revolution is not just a strategic move—it’s a necessity for any company aiming to stay competitive and meet the evolving demands of today’s consumers.

The air fryer’s surge in popularity isn’t just a fad; it’s a testament to the evolving landscape of healthy cooking. Consumers are increasingly seeking healthier alternatives to traditional frying methods, which often involve high levels of oil and unhealthy fats. The air fryer, with its ability to mimic the taste and texture of fried foods while using a fraction of the oil, has become a staple in many kitchens.

This shift towards healthier cooking is driven by several factors. Health consciousness is on the rise, with more people looking for ways to reduce their intake of saturated fats and calories. Convenience is another key driver, as the air fryer offers a quick and easy way to prepare a variety of foods with minimal cleanup. Additionally, the rise of social media has played a significant role, with influencers and chefs showcasing the versatility and deliciousness of air-fried dishes.

The air fryer’s design is another factor contributing to its success. It uses a circulating fan to distribute hot air around the food, creating a crispy outer layer without the need for excessive oil. This not only reduces the calorie content of the food but also makes it more appealing to health-conscious consumers. The appliance is versatile, capable of cooking a wide range of foods, from vegetables and meats to desserts and snacks.

The market for air fryers has grown exponentially, with manufacturers responding to consumer demand by introducing new features and models. Smart technology, for instance, has become a standard in many newer models, allowing users to control their appliances remotely via smartphones. This integration of technology into kitchen appliances reflects a broader trend in the industry.

As the market expands, so does the need for efficient production. Enter the automated air fryer assembly line, a marvel of modern manufacturing that is transforming how these appliances are produced. This line is not just about speed; it’s about precision, quality, and sustainability.

Innovation in the assembly line process is key to meeting the demands of a rapidly growing market. One such innovation is the integration of robotics, which can handle tasks that were once the realm of human labor. Robots are precise and consistent, reducing the likelihood of defects in the final product. They can also work tirelessly, 24⁄7, without breaks, increasing production capacity and efficiency.

Another innovation is the use of advanced sensors and software to monitor and adjust the assembly process in real-time. This ensures that each air fryer meets the highest quality standards, regardless of the volume being produced. The software can also predict maintenance needs, reducing downtime and keeping the line running smoothly.

Energy efficiency is a crucial consideration in the assembly line process. With the growing emphasis on sustainability, manufacturers are investing in energy-saving technologies. LED lighting, for example, is being used to illuminate the assembly area, providing ample light while using less energy than traditional bulbs.

The benefits of an automated air fryer assembly line are numerous. For one, it allows for the mass production of air fryers at a much faster rate than manual assembly. This scalability is essential as the market continues to expand, ensuring that manufacturers can keep up with demand.

Moreover, the quality of the final product is significantly improved. The precision of robotic assembly reduces the number of defects, ensuring that each air fryer that leaves the line is of the highest quality. This not only enhances customer satisfaction but also reduces the cost of returns and replacements.

Another significant benefit is the reduction in labor costs. While the initial investment in robotics and automation can be substantial, over time, it can lead to significant savings. By automating the assembly process, manufacturers can reduce their reliance on a large workforce, which can be costly and prone to errors.

In the realm of market insights, the trend towards healthier cooking methods is a clear indicator of where the industry is heading. As more consumers adopt air fryers, the market for related products, such as air fryer accessories and recipe books, is also expected to grow. This presents opportunities for manufacturers to expand their product lines and cater to the evolving needs of consumers.

The rise of e-commerce has also changed the game for the air fryer industry. With more consumers shopping online, there’s a greater need for efficient logistics and supply chain management. This is where an automated assembly line can play a crucial role, ensuring that products are produced quickly and shipped promptly to customers around the world.

Lastly, the global outlook for the air fryer market is promising. As health and wellness continue to be top priorities for consumers, the demand for air fryers is expected to remain strong. Emerging markets, particularly in Asia and Latin America, are showing significant growth, offering new opportunities for manufacturers to expand their reach.

In conclusion, the automated air fryer assembly line is not just a technological advancement; it’s a strategic move that aligns with the industry’s trends and consumer preferences. By embracing innovation and efficiency, the air fryer industry is poised for continued growth and success.

In the world of kitchen appliances, a few brands have managed to carve out a niche with their innovative approach to air fryer production. Let’s delve into a couple of case studies that showcase successful implementations of automated assembly lines.

Case Study 1: Brand A’s Leap Forward

Brand A, known for its commitment to eco-friendly appliances, embarked on a transformative journey by integrating an automated air fryer assembly line. Their previous manual process was time-consuming and prone to errors, leading to inconsistent product quality.

The new assembly line featured robotic arms that meticulously placed components, ensuring precision and reducing the likelihood of human error. This not only increased production speed but also minimized waste. The result was a significant boost in output without compromising on quality, making Brand A a leader in sustainable kitchen appliance manufacturing.

Case Study 2: Efficiency Through Customization

Company B, a well-established player in the market, recognized the need for an automated assembly line to keep up with the growing demand for customized air fryers. Their customers sought not just high-quality appliances but also unique features tailored to their preferences.

The automated line at Company B allowed for seamless customization. Special software programs enabled the integration of various options, from different types of heating elements to unique color schemes. The line’s flexibility meant that each unit could be uniquely configured, meeting customer expectations while maintaining efficiency.

Case Study 3: Quality Control at Scale

Another brand, C, faced the challenge of scaling up their production without sacrificing the stringent quality standards they had set. The introduction of an automated air fryer assembly line was the key to achieving this balance.

The assembly line at Brand C included advanced quality control systems. High-resolution cameras scanned each fryer during the assembly process, checking for defects in the components and ensuring that the final product met the brand’s high standards. This automated inspection process was crucial in maintaining consistency and reducing the number of faulty units that reached the market.

Case Study 4: The Human Touch in Automation

Brand D took a different approach by combining automation with a strong emphasis on employee training and engagement. Their assembly line was state-of-the-art, featuring a mix of robotics and human labor.

The robots took care of repetitive tasks, such as welding and soldering, while human technicians oversaw the more intricate and delicate aspects of the assembly. This hybrid model allowed for a faster production rate without compromising on the attention to detail that high-quality air fryers require.

Case Study 5: The Global Impact

An international appliance manufacturer, E, faced the challenge of meeting the diverse demands of global markets. Their automated air fryer assembly line was designed to be adaptable, allowing for quick modifications to cater to different regulatory standards and consumer preferences across the world.

The line was a marvel of adaptability, capable of producing air fryers that met European safety regulations, American certifications, and even specific regional preferences. This global success was a testament to the power of an automated assembly line that could evolve with the market.

In each of these case studies, the successful implementation of an automated air fryer assembly line has led to significant improvements in efficiency, quality, and customer satisfaction. As the kitchen appliance industry continues to evolve, these examples serve as inspiration for other brands looking to stay ahead in the competitive landscape.

In the ever-evolving landscape of kitchen appliances, the future prospects are as diverse as they are promising. Challenges, too, are present, but they are not insurmountable. The rise of smart homes and the increasing demand for healthier lifestyles are reshaping the industry. Here are some key considerations for what lies ahead.

The integration of IoT (Internet of Things) is expected to become more prevalent, allowing appliances to communicate and interact with each other seamlessly. This interconnectedness could lead to more personalized and efficient cooking experiences. As technology advances, so does the potential for predictive maintenance, reducing downtime and ensuring appliances are always at peak performance.

Sustainability is another area poised for significant growth. As consumers become more environmentally conscious, manufacturers are under pressure to produce appliances that are not only efficient but also eco-friendly. This shift could mean the use of recycled materials, energy-efficient designs, and longer-lasting components.

Energy efficiency remains a top priority. With the global push towards renewable energy and lower carbon footprints, appliances that consume less power will be increasingly valued. Innovations like energy-saving modes and adaptive controls will likely become standard features in the next generation of kitchen appliances.

Safety is always a paramount concern. As technology becomes more complex, ensuring that appliances are reliable and secure against hacking or misuse will be crucial. This may involve developing new safety protocols and encryption methods to protect user data and appliance functions.

Regulatory compliance is a constant challenge. Different markets have varying standards and certifications that manufacturers must adhere to. Keeping up with these requirements can be daunting, but it is essential for market access and consumer trust.

On the challenge front, one significant issue is the cost of innovation. Developing new technologies and integrating them into appliances can be expensive, which may lead to higher price points for consumers. Balancing the need for innovation with affordability will be a delicate balance for manufacturers.

The rise of e-commerce has changed how consumers interact with kitchen appliances. Online shopping means that customers can compare products, read reviews, and make informed decisions from the comfort of their homes. This shift has also necessitated a focus on packaging and logistics, ensuring that delicate appliances arrive in perfect condition.

Another challenge is the rapid pace of technological change. The time it takes to develop a new appliance can be short, and what’s cutting-edge today might be outdated tomorrow. Companies must stay agile and adaptable to keep up with these rapid shifts.

The future of kitchen appliances is also tied to the global economy. Economic downturns can lead to reduced consumer spending, while economic booms can fuel innovation and expansion. Companies need to be prepared for both scenarios and have contingency plans in place.

In conclusion, the future prospects for the kitchen appliance industry are bright, with opportunities for innovation, sustainability, and efficiency. However, navigating the challenges of cost, compliance, and market dynamics will require strategic planning and a commitment to continuous improvement. Only those companies that can embrace change, invest in technology, and prioritize the needs of their customers will thrive in this dynamic landscape.

In the ever-evolving landscape of kitchen appliances, the air fryer has emerged as a true game-changer. It’s not just a gadget; it’s a culinary revolution that’s reshaping how we think about healthy cooking. Let’s delve into why this nifty little appliance is causing such a stir.

The air fryer uses hot air to circulate around food, creating a crispy outer layer while retaining the moisture and nutrients inside. This method slashes the amount of oil needed compared to traditional frying, making it a favorite among health-conscious consumers. From crispy fries to golden-brown chicken, the possibilities are endless, and the results are nothing short of amazing.

As the air fryer’s popularity soars, so does the demand for a more efficient and streamlined production process. Enter the automated air fryer assembly line, a beacon of innovation that promises to transform the industry. Here’s why such a line is not just necessary but essential for the growth and sustainability of the air fryer market.

The assembly line process has been a cornerstone of manufacturing efficiency for decades. By automating this process, manufacturers can achieve a level of precision and consistency that manual assembly simply cannot match. Each component is meticulously placed and tested, ensuring that every air fryer that rolls off the line meets the highest standards of quality.

Quality control is paramount in the kitchen appliance industry. An automated assembly line allows for real-time monitoring and immediate feedback, catching any defects before they become a problem. This not only ensures that customers receive a reliable product but also reduces the risk of recalls and the costs associated with them.

Energy consumption and resource management are critical concerns in today’s world. An automated assembly line can significantly reduce energy use through optimized processes and the use of energy-efficient equipment. Additionally, the reduction in manual labor means less water and fewer materials are used, contributing to a more sustainable production process.

The benefits of an automated air fryer assembly line are clear, but they don’t stop there. Consistency is key in the appliance market, and an automated line delivers it in spades. Each unit is produced with the same level of quality, ensuring that customers receive a consistent experience with every use.

Moreover, the efficiency of an automated line allows for quicker production times. This means manufacturers can respond to market demands faster, reducing lead times and increasing inventory turnover. In a competitive market, this can be the difference between a company that thrives and one that struggles.

Cost savings are another significant advantage. While the initial investment in an automated assembly line can be substantial, the long-term benefits far outweigh the costs. Reduced labor expenses, lower energy consumption, and fewer errors all contribute to a more cost-effective production process.

The air fryer market is not just growing; it’s expanding rapidly. Consumer demand for healthier cooking options is on the rise, and the air fryer is perfectly positioned to capitalize on this trend. As the market continues to grow, the need for an automated assembly line becomes even more pronounced.

Industry trends are pointing towards a future where technology plays a pivotal role in kitchen appliances. Smart features, connectivity, and energy efficiency are becoming standard expectations. An automated assembly line is not just a tool for production; it’s a step towards creating the next generation of kitchen appliances.

The global outlook for automated assembly lines is promising. As more companies recognize the benefits, the technology is expected to become more accessible and widespread. This will lead to increased competition and innovation, ultimately benefiting consumers with better products and more choices.

Case studies from successful implementations of automated assembly lines in other industries provide a glimpse into what the future holds for the air fryer market. Companies like XYZ Appliance have seen dramatic improvements in production quality, speed, and cost savings, setting a precedent for others to follow.

As we look to the future, the prospects for the air fryer industry with automation are bright. Challenges, however, are inevitable. Keeping up with technological advancements, ensuring compliance with safety standards, and managing the transition from manual to automated processes will be key.

In conclusion, the automated air fryer assembly line is not just a trend; it’s a revolution. It’s changing how we produce, consume, and think about kitchen appliances. As the industry continues to evolve, the air fryer stands as a shining example of how innovation can lead to a healthier, more efficient, and more sustainable future.