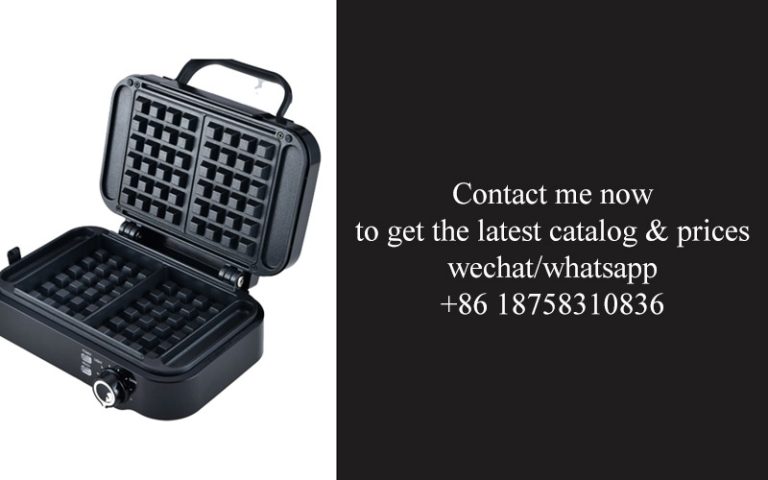

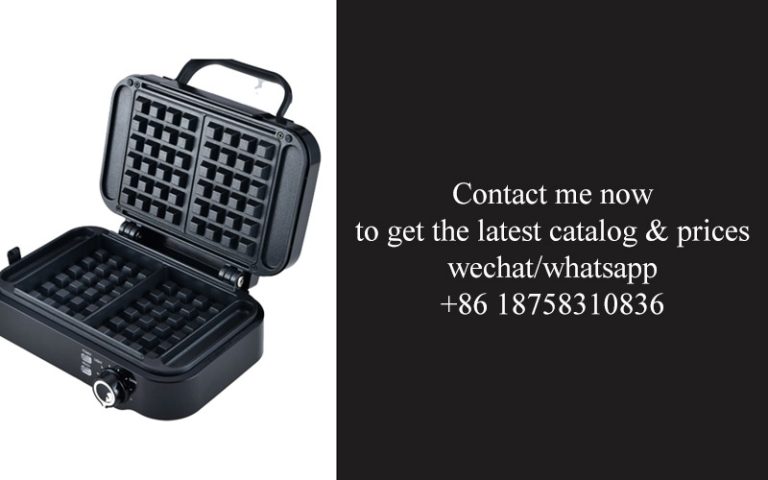

The continuous operation waffle iron plant represents a giant advancement in baking era, imparting functions that beautify efficiency and productiveness. those cutting-edge production lines integrate automation, intelligence, and energy-saving technology, bearing in mind seamless, excessive-quantity manufacturing of waffles. Key functions consist of a modular layout for easy maintenance, a person-pleasant interface, computerized cleaning, and protection measures like overheat safety. those advancements no longer handiest streamline the baking technique however also deliver steady quality and environmental blessings, making the continuous operation waffle iron plant a crucial thing inside the baking industry’s technological evolution.

the combination of global culinary cultures has spurred innovation in kitchen home equipment, specifically inside the OEM marketplace for cast aluminum waffle iron baking pans. these pans, favored for their unique texture and aesthetically desirable designs, are in excessive demand due to their outstanding thermal conductivity and sturdiness. As consumers seek customization and health-aware alternatives, producers are specializing in multi-practical designs, wise automation, and

substances to satisfy evolving market needs. With the upward push of smart homes and the worldwide growth of the baking industry, the market potential for those baking home equipment is sizable, using opposition and non-stop development amongst manufacturers.

The hydraulic press production industry in China is witnessing massive boom, pushed by way of the increasing demand for automation and performance in numerous sectors. With a robust marketplace base and aggressive panorama, chinese language organizations are investing in technological advancements to enhance their products. these innovations encompass automation, light-weight layout, excessive-performance materials, and energy-saving technology, positioning the industry for persisted expansion. the combination of smart solutions and modular designs is similarly propelling performance and customization, even as the global marketplace’s rising demand for excessive-stop production skills is anticipated to gasoline enterprise boom.

The NSF-licensed industrial waffle iron market is experiencing robust boom, pushed through purchaser call for for wholesome, convenient waffles. With a focal point on nutrition and excellent, these waffle irons are gaining reputation, particularly in cities, where they cater to a diverse variety of culinary wishes. Technological advancements, including smart temperature manipulate and non-stick substances, enhance person revel in and market competitiveness. The marketplace is segmented to include specialised health-conscious fashions, further boosting sales. As global call for grows, these waffle irons are poised to make bigger into global markets, with NSF certification serving as a key differentiator and access barrier.

The ISO 22000 meals safety preferred is important for kitchen equipment factories, ensuring a complete protection management gadget from raw cloth procurement to very last product cargo. This widespread demands non-stop development and emphasizes chance evaluation, improving logo popularity and compliance. through imposing ISO 22000, businesses can optimize supply chains, lessen dangers, and meet stringent safety demands, thereby bolstering their aggressive side in the market.

The double-sided flip waffle maker for meals vans represents a modern innovation in kitchen appliances, designed to beautify cooking performance and flexibility in mobile kitchens. Its precise double-sided turn layout permits for simultaneous waffle manufacturing, catering to the quick-paced needs of meals truck operations. This appliance not handiest meets the portability and space constraints of food trucks however also boasts clever temperature manipulate and energy-saving features, aligning with the industry’s shift closer to sustainability and performance. As a key component in food truck kitchen appliances, the double-sided turn waffle maker has the potential to redefine the market with its multifunctional and person-friendly technique.

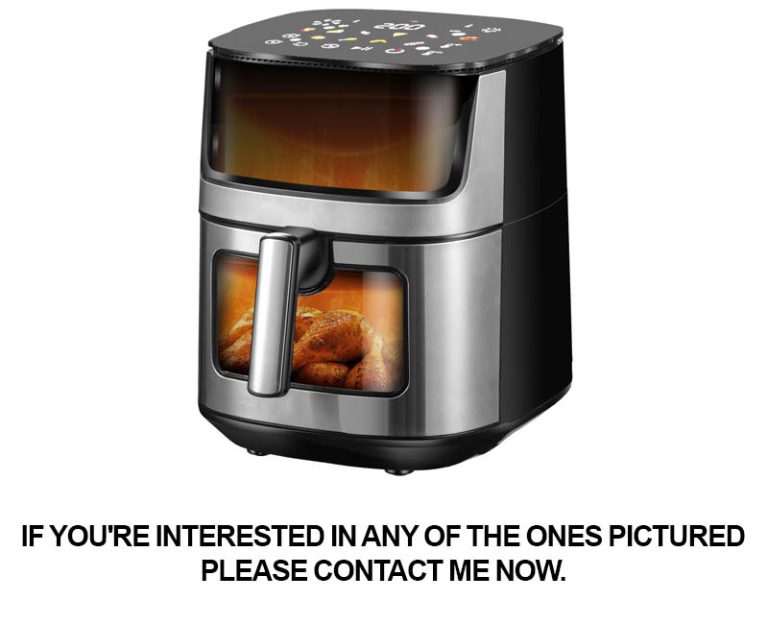

The kitchen appliance enterprise is witnessing a transformative shift with the upward push of ceramic-coated waffle irons and BPA-unfastened substances. those improvements offer more desirable cooking stories, improving the safety and aesthetic appeal of home equipment. Ceramic coatings on waffle irons provide non-stick surfaces, smooth cleaning, and healthier options to standard materials, at the same time as BPA-loose substances cope with fitness concerns by way of casting off dangerous components. This fashion is not best revolutionizing the functionality of kitchen gear however also aligning with customer demands for healthier, greater sustainable cooking alternatives.

The kitchen equipment enterprise is evolving with a focus on innovation and customization. The 20-day speedy ODM sample provider, exemplified by using the Waffle Baker’s new product release, showcases this fashion. This carrier hurries up the design-to-market system, bearing in mind brief reaction to marketplace demands and patron comments. The Waffle Baker’s new waffle maker blends modern layout with fitness-aware capabilities, emphasizing each fashion and capability. This approach, together with the capacity of Kitchen appliance ODM offerings, is driving enterprise increase and meeting the sophisticated wishes of modern-day consumers.

The kitchen appliance marketplace is experiencing a surge in call for for NSF/ANSI four certified waffle makers, emphasizing protection and innovation. these clever waffle irons offer convenient cooking with superior functions like touch display operation and cellphone app integration, making sure unique texture and appearance. Their versatility caters to diverse alternatives, health-conscious diets, and busy existence. With strict material and hygiene standards, these waffle makers aren’t most effective a symbol of protection however additionally a trendsetter for environmentally friendly and user-centric appliances.

The UL 197 business fashionable has emerged as a pivotal benchmark for kitchen equipment safety, considerably influencing marketplace tendencies and innovation. This rigorous fashionable ensures that kitchen home equipment meet stringent safety requirements, from electric safety to fabric resilience, and usefulness. As a end result, producers are investing in superior protection technology, leading to the improvement of smarter, more secure, and extra

kitchen home equipment. This shift is not best enhancing client self belief but additionally fostering a aggressive panorama that drives continuous development and adherence to the UL 197 wellknown.