Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

With the acceleration of life’s pace and purchasers’ pursuit of handy delicacies, the kitchen equipment enterprise has welcomed new improvement opportunities. particularly within the ecu and American markets, the non-stop operation waffle iron, due to its specific texture and convenient operation, has won substantial popularity. this newsletter will delve into the market tendencies and needs of this product, and examine the technological innovation and product features in the back of it.

The non-stop operation wafer biscuit production line, as an green baking equipment, integrates automation and intelligence, able to attaining non-stop batch production of wafer biscuits. The manufacturing line consists of more than one modules, inclusive of the raw fabric pre-blending machine, molding machine, baking gadget, cooling and conveying system, and packaging device, all designed to fulfill the demands of massive-scale manufacturing.

in the uncooked material pre-blending machine, the production line ensures regular system for each wafer biscuit by particular dimension and combining of elements. The molding device is answerable for urgent the blended batter into standard shapes, making sure the advent and pleasant of the product. The baking machine utilizes multi-stage heating technology to obtain best baking effects for the wafer biscuits in a brief time while retaining their texture and nutrients.

The cooling and conveying machine is responsible for quick cooling the freshly baked wafer biscuits to save you deformation or sticking due to excessive temperature. subsequently, the packaging system automatically completes the sealing and labeling strategies, making sure the product is in choicest circumstance before it leaves the manufacturing facility. during the manufacturing procedure, the automatic manage gadget monitors each stage in actual-time to make certain the stability of the production system and the reliability of product exceptional.

The design of the non-stop operation wafer biscuit production line takes full attention of manufacturing performance and strength conservation and environmental protection. The equipment is modular in design, facilitating protection and improvements. moreover, the production line adopts advanced strength-saving technologies such as warmth healing and occasional-strength intake heating factors, successfully lowering production charges and enhancing the economic blessings of the company.

five. With the increasing demand for baked products among purchasers, the continuous operation wafer biscuit manufacturing line is gaining reputation in the market. especially inside the catering chain and baking manufacturing facility industries, this production line has end up the preferred system for improving manufacturing efficiency and lowering hard work depth.

The technical features of the manufacturing line additionally include an clean-to-perform human-machine interface, fault caution, and remote diagnostic functions, making the line now not simplest able to meeting the wishes of large-scale production but additionally imparting efficient and strong operation guarantees. moreover, the design of the production line takes into account hygiene requirements, making it less complicated to gain a easy and standardized production surroundings.

In precis, the non-stop operation wafer biscuit production line, with its features of automation, continuity, and energy efficiency, has become an vital development route in the kitchen equipment industry. As era continues to advance and the market is further expanded, such production lines are expected to play a greater role in the baking industry.

With the upward thrust of worldwide fitness-conscious lifestyles, consumer hobby in baked goods has been at the upward push, and waffles, because of their versatile flavors and convenient quick-provider nature, have visible a steady increase in market call for. marketplace trend evaluation reveals several key factors which might be huge for the continuous operation of waffle production strains:

fitness-oriented baking trend: The client’s pursuit of healthy meals has prompted the baking enterprise to shift towards low-sugar, low-fats, and entire-grain options. continuous operation waffle machines can correctly produce waffles that meet health standards, pleasurable the marketplace’s call for for healthful meals.

various product necessities: The marketplace demands a variety of waffle flavors and shapes, starting from conventional candy to savory, fruit-flavored, or even personalised customization. continuous operation manufacturing traces can meet exclusive purchaser options via brief mould changes and recipe modifications.

Automation fashion: With growing labor expenses and increased manufacturing performance requirements, computerized manufacturing lines have become crucial for corporations to reduce costs and growth ability. non-stop operation waffle machines enable a totally automated production manner from uncooked material coaching to completed product packaging through computerized manage.

fast-intake tradition: the quick-paced way of life has caused an improved call for for quick and handy food. continuous operation waffle gadget production lines can gain non-stop operation, assembly the demand for fast deliver from rapid-meals chains, convenience shops, and different channels.

worldwide market expansion: As an internationalized baked properly, waffles have tremendous marketplace ability. non-stop operation waffle system production traces, with their excessive production performance and balance, assist corporations make bigger into remote places markets and cater to the intake conduct of various international locations and regions.

Environmental consciousness enhancement: With the developing environmental focus, clients are paying extra attention to environmental measures inside the manufacturing manner. non-stop operation waffle device manufacturing traces undertake power-saving technology and environmentally pleasant substances, helping organizations set up a green manufacturing photo.

Technological innovation drive: The marketplace’s technical requirements for continuous operation waffle system manufacturing strains are continuously increasing, inclusive of functions including intelligence, modularization, and ease of maintenance. Technological innovation not best improves production efficiency but also reduces maintenance prices, improving the marketplace competitiveness of products.

In precis, continuous operation waffle gadget manufacturing traces display clean blessings in marketplace fashion and call for analysis, turning into a brand new riding pressure for the improvement of the baking industry. agencies have to hold up with market trends, continuously innovate and optimize manufacturing strains to fulfill the dual demands of clients and the market.

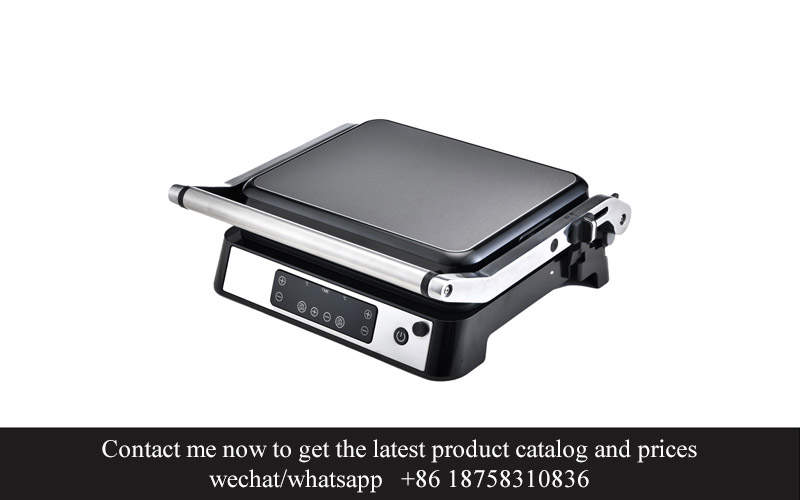

The continuous operation wafer iron production strains inside the eu and American kitchen equipment marketplace are experiencing an extraordinary wave of technological innovation. right here is an in depth analysis of the product features:

The layout of wafer irons has upgraded from traditional intermittent heating to non-stop heating, which means that the machines can produce non-prevent, significantly improving manufacturing efficiency. the new fashions usually have the subsequent first rate features:

green Heating gadget: the brand new wafer irons use fast heating tubes, blended with particular temperature manipulate technology, to attain the set temperature in a brief time, ensuring consistent taste in every wafer iron produced.

clever Operation Interface: present day wafer irons are normally equipped with a touch screen operation interface, permitting customers to set parameters consisting of temperature and time via intuitive menus, making operation simple and lowering human errors.

automatic cleaning feature: to fulfill the call for for continuous manufacturing, the new technology of wafer irons are built with an automatic cleaning program, that can effortlessly clean the inner warmth exchangers and heating plates with easy operations, saving maintenance time and exertions fees.

four. safety safety Measures: To prevent overheating and accidental electric shock, continuous operation wafer irons are prepared with more than one protection protection systems, together with overheat safety, leakage protection, and emergency forestall buttons, making sure the protection of operators.

five. Structural Optimization: the new models have optimized the structural layout, using light-weight substances to lessen the overall weight of the gadget at the same time as enhancing balance. additionally, the detachable component design makes machine renovation and cleaning greater handy.

electricity performance improvement: With the enhancement of environmental consciousness, the brand new technology of wafer irons has considerably improved electricity efficiency, using power-saving heating elements and wise temperature control generation to efficiently reduce energy intake.

assorted features: to fulfill the desires of various clients, a few wafer irons have also introduced multifunctional designs, including the potential to make wafer irons of various shapes, sizes, and thicknesses, even adjustable texture intensity, supplying a diffusion of product selections.

In precis, the technological innovation of non-stop operation wafer iron manufacturing strains no longer handiest improves production performance however also brings extra handy, secure, and environmentally friendly merchandise to purchasers. as the market keeps to increase and patron demands diversify, it’s miles anticipated that wafer irons inside the future can have extra plentiful functions and extra consumer-pleasant designs to meet the new developments in the international kitchen appliance market.