Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving world of kitchen appliances, a new wave of innovation is reshaping how we cook and dine. At the heart of this transformation lies the integration of advanced manufacturing techniques, such as integrated metal stamping, which is not only enhancing the functionality of kitchenware but also pushing the boundaries of design and efficiency. This article delves into the world of sandwich plates and explores how integrated metal stamping is revolutionizing their design and performance.

The kitchen, once a realm of simple cooking and occasional culinary experimentation, has now transformed into a hub of innovation and technology. This shift is not just a trend but a testament to the rapid advancement in the appliance industry. Enter the era of smart kitchens, where the fusion of cutting-edge technology and everyday cooking tools is reshaping how we interact with our culinary spaces.

With the integration of smart devices and appliances, kitchens are becoming more efficient, user-friendly, and even predictive in their capabilities. Imagine a scenario where your refrigerator suggests recipes based on the ingredients you have, or your oven preheats itself before you even think about setting the timer. This is the reality that smart kitchens are bringing to our homes.

The driving force behind this revolution is the increasing demand for convenience, efficiency, and personalization. As our lives become busier, we seek solutions that can save us time and energy while still delivering high-quality results. Smart kitchens are the answer to these needs, promising a seamless blend of technology and culinary artistry.

Gone are the days when a kitchen was just a collection of appliances. Now, it’s a connected ecosystem where each device communicates with the others to create a cohesive and intelligent environment. This interconnectedness is not just limited to appliances; it extends to lighting, storage solutions, and even the kitchen itself, which can now be controlled through a single interface or even with voice commands.

One of the key players in this transformation is the integration of smart features into everyday kitchen tools. Take, for instance, the humble knife. Once a simple tool, it can now be part of a smart kitchen ecosystem that tracks its usage, sharpens it automatically, and even suggests recipes that would best utilize its blade. This level of personalization is what sets smart kitchens apart from traditional ones.

The rise of smart kitchens is also driven by the younger generation, who are more tech-savvy and open to adopting new technologies. They are the ones leading the charge in embracing smart appliances and systems, pushing manufacturers to innovate and create more advanced and user-friendly products.

In terms of market trends, the smart kitchen industry is expected to grow significantly over the next few years. According to a report by Grand View Research, the global smart kitchen market size is projected to reach USD 47.1 billion by 2025, with a CAGR of 8.5% from 2018 to 2025. This growth is fueled by factors such as increasing urbanization, rising disposable incomes, and the growing preference for convenience and health-conscious eating habits.

The design of smart kitchens has also evolved to cater to these changing demands. Modern kitchens are no longer just about aesthetics; they are about functionality and adaptability. Kitchens are being designed with flexible layouts that can accommodate various appliances and technology upgrades. Open-concept kitchens, which are becoming increasingly popular, allow for a seamless flow of technology and space, making the kitchen a central hub in the home.

In addition to the technological advancements, there is also a growing emphasis on sustainability in smart kitchen design. Appliances are becoming more energy-efficient, and materials are being sourced responsibly to reduce the environmental impact. Smart kitchen systems are also being developed to monitor and optimize energy usage, further contributing to a greener lifestyle.

The rise of smart kitchens is not just a trend; it’s a paradigm shift in how we live and interact with our living spaces. It’s about making life easier, healthier, and more enjoyable through technology. As we continue to embrace these innovations, the kitchen is poised to become an even more integral part of our daily lives, not just a place to cook, but a space where technology and culinary expertise come together to create a truly smart home.

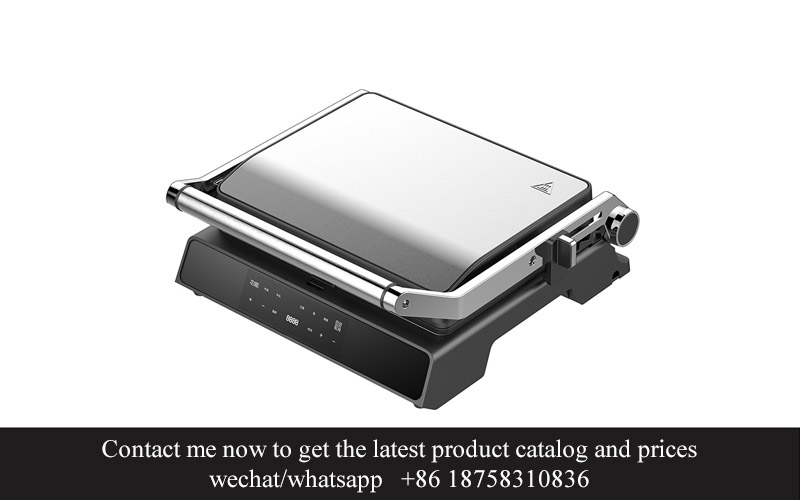

In the heart of modern culinary landscapes, sandwich plates have emerged as a cornerstone of innovation. These aren’t your average kitchenware; they are the unsung heroes of the contemporary kitchen, blending functionality with style. To truly grasp their significance, let’s delve into the intricacies of sandwich plates in today’s cooking world.

Sandwich plates, often misconstrued as simple, flat surfaces, are far more complex. They are the canvas upon which culinary artistry is painted, offering chefs and home cooks alike a variety of surfaces to craft their masterpieces. These plates are designed with an array of features that cater to the diverse needs of modern cooking.

One of the key aspects of sandwich plates is their versatility. They come in various materials, from traditional ceramic to sleek glass, and even eco-friendly bamboo. Each material brings its own set of benefits, from the heat resistance of ceramic to the durability of glass. This variety allows for a seamless integration into different cooking styles and preferences.

The design of sandwich plates has evolved to accommodate the latest cooking techniques. Non-stick surfaces have become standard, making them ideal for delicate dishes that require careful handling. Grilled cheese enthusiasts will appreciate the ability to sear their sandwiches to perfection, thanks to the high-heat tolerance of these plates. Additionally, the inclusion of grooves and ridges on some models adds texture to the sandwiches, enhancing the overall eating experience.

Functionality is another hallmark of modern sandwich plates. Many are designed with integrated features that make cooking easier and more efficient. For instance, some plates come with built-in temperature controls, ensuring that food is cooked to the desired level of doneness. Others have removable inserts that can be used for steaming or baking, offering a multi-functional approach to meal preparation.

In the realm of sustainability, sandwich plates have also made significant strides. Eco-conscious consumers will be pleased to know that there are now options made from recycled materials or those that are biodegradable. These plates not only contribute to a greener kitchen but also encourage a more mindful approach to consumption.

The aesthetic appeal of sandwich plates cannot be overlooked. They are no longer just utilitarian tools; they are statement pieces that reflect the personality of the user. With sleek designs and vibrant colors, these plates have become a part of the kitchen decor, enhancing the overall ambiance of the space.

Moreover, sandwich plates have become a canvas for culinary creativity. Chefs are experimenting with different shapes and sizes, creating unique presentations that not only delight the palate but also the eye. The possibilities are endless, from the classic round or square shapes to the more adventurous hexagonal or triangular designs.

In the world of cooking, trends come and go, but the sandwich plate has managed to remain relevant. This is due in part to its adaptability. Whether it’s a gourmet sandwich at a high-end restaurant or a quick lunch at home, sandwich plates are there to serve. They have evolved to cater to the fast-paced lifestyle of today’s society, where convenience meets quality.

The technology behind sandwich plates has also advanced. Smart features, such as digital temperature readouts and wireless connectivity, are becoming more common. These innovations allow users to monitor their cooking process remotely, ensuring that every sandwich is cooked to the perfect temperature.

In the realm of health and wellness, sandwich plates have also played a role. With the rise of clean eating and the emphasis on whole foods, these plates are designed to be easy to clean and sanitize, reducing the risk of cross-contamination. This is particularly important for those who follow specific dietary guidelines or have food allergies.

In conclusion, sandwich plates have become an integral part of modern cooking. They are not just kitchen tools but also reflections of the culinary evolution that has taken place over the years. From their versatile designs to their smart features, sandwich plates continue to shape the way we cook and enjoy our meals. Whether you’re a professional chef or a home cook, these plates are a testament to the endless possibilities that lie within the heart of the kitchen.

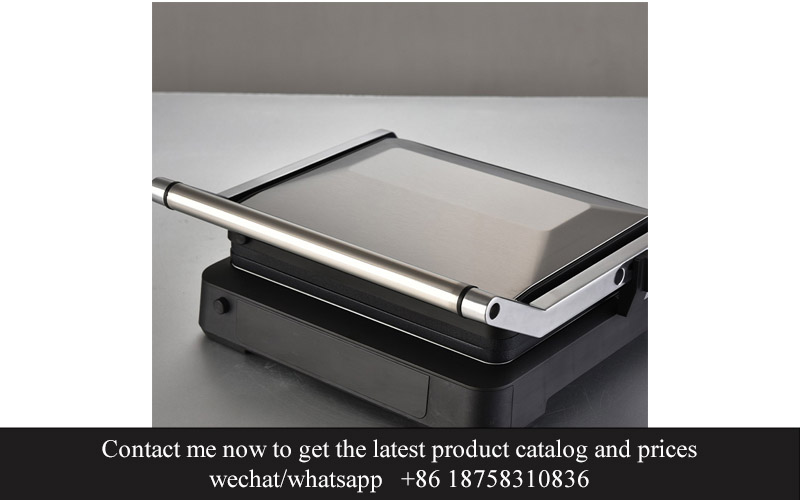

Integrated metal stamping is a precision metal forming process that has revolutionized the manufacturing industry, including the production of kitchen appliances. This technique involves the use of specialized machinery to shape flat sheets of metal into three-dimensional shapes with high accuracy and efficiency. Let’s delve into the intricacies of this process and its significance in modern cooking.

The process begins with the selection of the appropriate metal material, which is typically a high-strength steel or aluminum due to its malleability and durability. These sheets are then fed into a stamping press, where they are clamped tightly between a pair of dies. The dies are intricately designed to create the desired shape, whether it’s a simple profile or a complex component.

Once the metal is clamped, the press applies immense pressure, which causes the metal to deform and conform to the shape of the die. This deformation can take various forms, including bending, stretching, or piercing, depending on the design of the die. The force exerted by the press is so powerful that it can transform the metal into intricate patterns and shapes that would be impossible to achieve through traditional forging or casting methods.

One of the key advantages of integrated metal stamping is its ability to create uniformity and consistency in the final product. The precision of the stamping process ensures that each component is identical, which is crucial for the assembly of complex appliances. In the context of sandwich plates, this uniformity translates to reliable performance and a longer lifespan for the appliance.

In the realm of kitchen appliances, sandwich plates are a critical component, often serving as the base or support structure for various cooking elements. These plates are designed to distribute heat evenly across the cooking surface, whether it’s a stovetop, oven, or other heat-generating appliance. The use of integrated metal stamping in the production of sandwich plates offers several benefits:

Strength and Durability: The metal used in stamping is typically chosen for its strength, which is essential for withstanding the heat and pressure of cooking. Stamped sandwich plates can withstand high temperatures without warping or bending, ensuring that they remain functional over time.

Precision and Consistency: The stamping process allows for the creation of precise patterns and contours, which are crucial for the even distribution of heat. The consistency in the manufacturing process ensures that each sandwich plate performs similarly, providing a consistent cooking experience.

Design Flexibility: Stamping allows for the creation of complex shapes and features that can enhance the functionality and aesthetics of sandwich plates. This flexibility can lead to innovative designs that not only perform better but also look sleeker and more modern.

Cost-Effectiveness: While the initial investment in stamping machinery can be significant, the process is highly efficient and can produce a large number of components in a short amount of time. This efficiency translates to lower production costs, which can be passed on to consumers.

Environmental Impact: Integrated metal stamping is a relatively clean and sustainable manufacturing process. It requires less energy compared to other metal forming methods and produces minimal waste, contributing to a more eco-friendly production cycle.

The process of integrated metal stamping involves several steps, each contributing to the final quality of the sandwich plate:

In conclusion, integrated metal stamping is a cornerstone technology in the production of sandwich plates for modern cooking appliances. Its ability to create precise, durable, and cost-effective components has played a significant role in the evolution of kitchen technology. As the demand for smart and efficient appliances continues to grow, the role of integrated metal stamping in shaping the future of kitchenware will undoubtedly remain pivotal.

In the ever-evolving world of kitchen appliances, sandwich plates have emerged as a cornerstone of modern cooking. These versatile tools are not just for sandwiches anymore; they are integral to a wide range of culinary creations. The design of sandwich plates has seen a surge in innovation, reflecting the demands of today’s kitchens.

The evolution of sandwich plates has been marked by a shift from simple, single-purpose tools to multifunctional, sleek devices that seamlessly integrate into the kitchen’s aesthetic. One notable trend is the incorporation of non-stick surfaces, which have made cooking a breeze and cleaning up a cinch. These surfaces are not only durable but also resistant to scratches, ensuring that the sandwich plates remain in top condition for years.

Another innovation is the introduction of adjustable heat settings. Modern sandwich plates often come with multiple temperature controls, allowing chefs to precisely manage the cooking process. Whether you’re toasting a slice of bread to perfection or cooking a gourmet sandwich, these settings ensure that every aspect of the meal is cooked to your liking.

The design of sandwich plates has also become more ergonomic. Handles that are contoured for comfort and ease of grip have become standard, reducing the strain on the hands and allowing for a more enjoyable cooking experience. Some models even feature non-slip bases, ensuring that the plate stays put on the countertop or table, no matter how vigorous the cooking gets.

One of the most significant innovations in sandwich plate design is the integration of smart technology. These plates can now be connected to smartphones or kitchen appliances through Bluetooth or Wi-Fi, allowing users to control the cooking process remotely. Imagine setting the sandwich plate to start toasting while you’re still in the shower—this level of convenience is now a reality.

The size and shape of sandwich plates have also seen changes. While traditional square or rectangular designs are still popular, there are now models that offer unique shapes, such as round or oval, which can add a touch of elegance to the kitchen and make it easier to cook certain types of dishes. Some plates even come with removable inserts, which can be used for different types of food, from sandwiches to omelets.

Safety features have also been a focal point in the design of modern sandwich plates. Many come with automatic shut-off functions that activate after a certain period of inactivity, preventing any potential fires. Additionally, some models are made from materials that are heat-resistant, ensuring that they can withstand high temperatures without warping or releasing harmful chemicals.

The inclusion of cooking guides and indicators has also become more sophisticated. Some sandwich plates now come with LED lights that show when the plate is at the optimal temperature for cooking, while others have built-in timers that alert you when your sandwich or other food is ready.

The design of sandwich plates has also embraced sustainability. Eco-friendly materials are being used to reduce the environmental impact, and some manufacturers are even offering plates that are fully recyclable. This commitment to sustainability not only benefits the planet but also appeals to consumers who are increasingly conscious of their ecological footprint.

In terms of aesthetics, sandwich plates have become a canvas for creativity. Manufacturers are now offering a wide range of colors and finishes, from classic black and stainless steel to vibrant reds and blues. This allows users to express their personal style and match their kitchen decor.

Lastly, the customization of sandwich plates has taken a leap forward. Some models now come with interchangeable parts, such as different-sized heating elements or non-stick surfaces, allowing users to tailor their sandwich plates to their specific needs and preferences.

In summary, the design of sandwich plates has transformed from a simple tool for making sandwiches into a multifaceted, innovative kitchen appliance that caters to the diverse needs of modern cooks. With each new innovation, sandwich plates continue to push the boundaries of what is possible in the kitchen, making cooking more enjoyable, efficient, and tailored to individual tastes.

In the realm of modern kitchenware, the sandwich plate has emerged as a versatile and innovative solution for both professional chefs and home cooks. These specialized plates are designed to create the perfect sandwich, offering a balance between functionality and aesthetic appeal. The role of integrated metal stamping in the design of sandwich plates is pivotal, as it shapes the very foundation of these culinary tools.

The integration of metal stamping into sandwich plate design brings a level of precision and durability that is hard to match with traditional manufacturing methods. Metal stamping involves the use of a stamping press to form metal sheets into the desired shape and size. This process is not only efficient but also allows for intricate details and uniformity that are crucial for the performance and longevity of the plates.

One of the key advantages of integrated metal stamping is the ability to create complex shapes and patterns that enhance the visual appeal of sandwich plates. The process allows for the creation of unique designs, such as embossed textures that mimic the look of artisanal bread or the sleek, modern lines that appeal to contemporary kitchens. These designs not only make the plates visually striking but also contribute to a more engaging and enjoyable cooking experience.

The structural integrity of sandwich plates is significantly enhanced through metal stamping. The metal sheets used in the process are typically stainless steel, anodized aluminum, or other robust materials that can withstand the rigors of daily use in a kitchen. The stamping process ensures that the plates are strong and resistant to warping, bending, or breaking, making them a reliable choice for both at-home and commercial kitchens.

Another crucial aspect where integrated metal stamping shines is in the creation of seamless joints. Sandwich plates often require multiple components to come together without any visible seams or gaps. Metal stamping allows for the precise alignment and joining of these components, resulting in a plate that is not only functional but also aesthetically pleasing. This seamless integration also means that the plate can be cleaned more effectively, reducing the risk of food particles becoming trapped in crevices.

The precision of metal stamping also plays a vital role in the thermal efficiency of sandwich plates. The even distribution of metal across the plate ensures that heat is conducted uniformly, allowing for the perfect grilling or toasting of sandwich ingredients. This is especially important for sandwich plates designed with a non-stick surface, which relies on the stamping process to create a smooth, heat-resistant finish.

In terms of customization, integrated metal stamping opens up a world of possibilities for designers and manufacturers. They can create sandwich plates tailored to specific tastes or kitchen aesthetics, from minimalist designs to those with intricate details that reflect a brand’s identity. This flexibility allows for a wide range of products to cater to different market segments and consumer preferences.

Moreover, the environmental impact of metal stamping is a point of consideration. The process is known for its efficiency, using less material and energy compared to other manufacturing methods. This not only reduces waste but also contributes to a more sustainable approach to kitchenware production.

In the context of sandwich plates, the role of integrated metal stamping is multifaceted. It not only contributes to the visual appeal and structural integrity of the plates but also ensures their functionality, durability, and environmental responsibility. As the demand for high-quality, innovative kitchenware continues to grow, the importance of metal stamping in the design and production of sandwich plates will undoubtedly remain a cornerstone of the industry.

In the world of kitchen appliances, sandwich plates have emerged as a crucial component, enhancing both the functionality and aesthetic appeal of modern cookware. Integrated metal stamping plays a pivotal role in the creation of these innovative sandwich plates, offering a myriad of benefits that elevate the cooking experience. Here’s a closer look at the advantages of this technology:

The precision and consistency of integrated metal stamping result in sandwich plates that are uniform in thickness and design. This uniformity ensures that heat is distributed evenly across the cooking surface, preventing hotspots that can burn or undercook food. The even heating allows for more precise control over cooking temperatures, whether you’re searing a steak or simmering a delicate sauce.

Metal stamping allows for the creation of intricate patterns and designs on sandwich plates. These patterns not only add a touch of style to your kitchen but also serve practical purposes. For instance, a textured surface can help to prevent food from sticking, making cleanup easier. The aesthetic value of these designs also complements modern kitchen aesthetics, making the cookware not just a tool but a statement piece.

The strength and durability of metal stamping are unmatched in the manufacturing of sandwich plates. The metal used in stamping is typically high-quality steel or aluminum, which is resistant to corrosion and heat. This durability means that sandwich plates can withstand years of use without losing their shape or performance. The robustness of these plates is especially beneficial for commercial kitchens where heavy use is the norm.

The process of integrated metal stamping is highly efficient, which translates to cost savings for manufacturers and, by extension, consumers. By producing sandwich plates in large quantities, the economies of scale reduce the per-unit cost. This efficiency also allows for quick turnaround times, ensuring that new designs and models can be brought to market rapidly to meet consumer demands.

One of the standout benefits of metal stamping is the ability to customize sandwich plates to specific requirements. Whether it’s a unique size, shape, or material composition, the stamping process can accommodate a wide range of customizations. This flexibility is particularly valuable in the foodservice industry, where specialized cookware is often needed to meet specific menu items or cooking techniques.

The environmental impact of manufacturing processes is a growing concern, and integrated metal stamping is a green choice. The metal used in stamping is recyclable, and the process itself generates minimal waste compared to other manufacturing methods. By choosing stamping, manufacturers contribute to a more sustainable future, which is increasingly important to eco-conscious consumers.

The precision of metal stamping ensures that sandwich plates are free of burrs or sharp edges, which can be a safety hazard in the kitchen. The smooth, finished edges of these plates not only reduce the risk of accidents but also contribute to a cleaner, more hygienic cooking environment. This attention to safety is a crucial factor in the design and production of kitchen appliances.

In terms of performance, the thermal conductivity of metal stamping materials is superior to many other materials used in cookware. This means that sandwich plates can heat up and cool down more quickly, leading to shorter cooking times and more energy-efficient cooking. The rapid response to temperature changes also makes these plates ideal for a variety of cooking methods, from searing to slow cooking.

The non-reactive nature of metal stamping materials ensures that sandwich plates won’t impart flavors or odors into the food being cooked. This is particularly important for delicate dishes that require the purity of the food’s natural flavors. The longevity of these plates also means that they can be used for a wide range of cooking tasks without the worry of altering the taste of the food.

The ease of maintenance is another significant benefit of integrated metal stamping. These plates are often dishwasher-safe, which simplifies the cleaning process and saves time for busy cooks. The resistance to corrosion and the non-stick surfaces of these plates also mean that they require less frequent cleaning and maintenance, making them a practical choice for any kitchen.

In conclusion, the benefits of integrated metal stamping for sandwich plates are multifaceted. From enhanced performance and safety to environmental sustainability and cost-effectiveness, this technology is reshaping the landscape of kitchen appliances. As consumers continue to seek out innovative and high-quality cookware, the advantages of metal stamping are becoming increasingly apparent in the design and production of sandwich plates.

In the realm of modern kitchen technology, several case studies highlight the successful implementations of integrated metal stamping in sandwich plates, showcasing not only the innovation but also the practicality of this technique. From commercial kitchens to home appliances, these examples underscore the versatility and benefits of using integrated metal stamping.

Innovative Cooking SystemsA notable case is the introduction of a high-end commercial kitchen line that utilizes integrated metal stamping in the design of their sandwich plates. These plates are not just functional but also contribute to the overall aesthetic of the kitchen. The stamping process allowed for intricate patterns and designs that are both visually appealing and durable, enhancing the brand’s image and customer experience.

Customization for High-End AppliancesAnother instance involves a luxury kitchen appliance brand that has embraced integrated metal stamping to offer customized sandwich plates. By using this technique, they are able to create plates with unique, personalized designs that cater to specific customer preferences. The result is a high-quality product that stands out in a competitive market, appealing to consumers who value individuality and craftsmanship.

Efficiency in Industrial ProductionA leading food service equipment manufacturer has leveraged integrated metal stamping to streamline the production of sandwich plates. The ability to produce complex shapes and sizes efficiently has reduced lead times and increased output. This case study demonstrates how the stamping process contributes to a more sustainable and cost-effective production cycle, which is crucial for large-scale industrial applications.

Improving Hygiene StandardsIn the healthcare sector, sandwich plates play a crucial role in maintaining cleanliness and preventing contamination. A hospital cafeteria has successfully implemented integrated metal stamping to create non-porous, easy-to-clean sandwich plates. The case study reveals that this innovation has significantly improved hygiene standards, leading to fewer health incidents and increased customer satisfaction.

Enhancing User Experience at HomeA popular home appliance brand has taken the leap into the kitchen technology market with integrated metal stamping sandwich plates. These plates offer a sleek design and are easy to handle, making them a favorite among consumers looking for both style and functionality. The case study highlights how the stamping process has allowed for the creation of a product that appeals to the modern, health-conscious consumer.

Adapting to Unique Market DemandsA small, niche market for gluten-free and allergy-friendly products has seen a rise in demand for specialized sandwich plates. By using integrated metal stamping, a local manufacturer has been able to produce these plates with specific features like deeper crevices for better grip and non-reactive materials that don’t alter the taste of the food. This case study is a testament to how the stamping process can be tailored to meet the exact needs of a particular market segment.

Sustainability and Eco-Friendly SolutionsAn eco-conscious company has adopted integrated metal stamping to create sandwich plates made from recycled materials. This case study not only showcases the technical capabilities of the stamping process but also the brand’s commitment to sustainability. The plates are not only durable and aesthetically pleasing but also contribute to a greener planet, resonating with environmentally conscious consumers.

Global Expansion and Market PenetrationA multinational foodservice company has expanded its global reach by integrating metal stamping into its sandwich plate production. This case study reveals how the stamping process has allowed them to adapt to local market preferences and regulations across different countries, ensuring that their products are both compliant and appealing to a diverse consumer base.

The Intersection of Art and FunctionalityFinally, an artisanal kitchenware brand has combined the art of metal stamping with the functionality of sandwich plates. The case study explores how this blend has created a product that is not just a tool for cooking but also a piece of art that enhances the dining experience. The attention to detail and craftsmanship in the stamping process has set this brand apart in the market, attracting collectors and culinary enthusiasts alike.

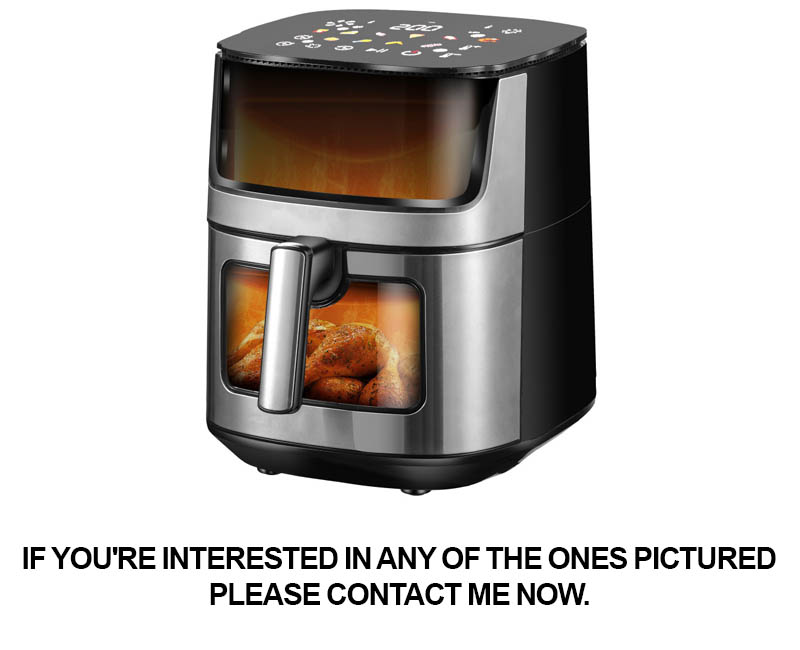

In the ever-evolving landscape of kitchen technology, the future of sandwich plates is poised to be shaped by a confluence of innovative design, advanced materials, and user-centric functionality. Here are some of the trends and predictions that are set to redefine the market:

The integration of smart technology is not just a buzzword but a reality that is rapidly becoming a staple in kitchen appliances. Imagine a sandwich plate that not only cooks your meal but also adjusts its settings based on the ingredients you’ve chosen, ensuring optimal flavor and texture. This level of personalization is not far off, with manufacturers already exploring AI-driven systems that can learn and adapt to individual preferences.

Sustainability is another driving force in the design of sandwich plates. As consumers become more environmentally conscious, there’s a growing demand for appliances that are not only efficient but also eco-friendly. This means materials that are recyclable, energy-saving features, and designs that minimize waste throughout the product’s lifecycle. The future sandwich plate might even incorporate biodegradable components, aligning with a broader shift towards greener living.

Modularity is a trend that’s catching on across various industries, and it’s no different in the world of kitchen appliances. Modular sandwich plates could offer a range of attachments and accessories, allowing users to customize their cooking experience. Think of a base unit that can accommodate different cooking surfaces, from grilling plates to steamers, all controlled through a single interface. This not only increases versatility but also extends the longevity of the appliance.

The rise of connected kitchen devices means that the sandwich plate of the future could be part of a larger network of appliances. Imagine being able to monitor and control your sandwich plate remotely, integrating it with your smart home system. Alerts for low ingredients, cooking progress updates, and even recipe recommendations could all become part of the standard feature set. This interconnectedness would not only enhance convenience but also provide valuable data that could be used to improve future models.

Health and wellness are at the forefront of consumer concerns, and the sandwich plate industry is responding by focusing on healthier cooking methods. Induction cooking, for example, is gaining popularity for its precision and efficiency, which can lead to lower calorie content in meals. The future sandwich plate might incorporate additional features like temperature control and cooking time adjustments to ensure that each sandwich is cooked to perfection without overcooking or burning.

Customization is becoming more accessible, with the ability to print and 3D design components for kitchen appliances. This means that in the future, you could have a sandwich plate that’s as unique as your kitchen. Users might be able to select from a variety of designs, materials, and even cooking elements to create a sandwich plate that fits their personal style and cooking needs.

Energy efficiency is a key consideration in the design of kitchen appliances, and sandwich plates are no exception. As energy costs continue to rise, manufacturers are looking for ways to reduce the power consumption of their products. This could involve the use of more efficient motors, advanced insulation, and intelligent power management systems that adjust to cooking loads.

The future also holds promise for increased safety features in sandwich plates. With the integration of sensors and smart controls, these appliances could be designed to prevent accidents, such as overcooking or burns. Additionally, voice-activated controls and intuitive interfaces could make these appliances accessible to a wider range of users, including those with physical limitations.

Lastly, the rise of subscription-based services could extend to kitchen appliances, with manufacturers offering ongoing maintenance, updates, and even the ability to swap out parts or accessories as needed. This model could provide a seamless experience for users, ensuring that their sandwich plates are always up-to-date with the latest technology and features.

In conclusion, the future of sandwich plates is bright with possibilities, driven by a combination of technological advancements, consumer demands, and environmental considerations. As these trends and predictions come to fruition, the sandwich plate could become an integral part of the modern kitchen, offering convenience, efficiency, and personalization like never before.

In the ever-evolving landscape of kitchen appliances, the future holds a myriad of possibilities that promise to revolutionize the way we cook and live. From smart interfaces to sustainable materials, the following trends and predictions paint a picture of a kitchen that is not only efficient but also harmonious with the environment.

The integration of AI and IoT (Internet of Things) technologies is set to become a cornerstone in the future of kitchen appliances. Imagine a scenario where your refrigerator not only keeps your food fresh but also suggests recipes based on the ingredients you have on hand. Smart ovens, equipped with voice-activated controls and the ability to connect to your smartphone, could become the norm, allowing for hands-free cooking and even remote monitoring.

Energy efficiency will remain a critical focus, with appliances becoming more adept at conserving power while delivering optimal performance. Innovations in thermal management, such as better insulation and energy recovery systems, will help reduce energy consumption and lower utility bills. This shift will not only benefit homeowners but also contribute to a smaller carbon footprint.

Sustainability will play a pivotal role in the development of new kitchen appliances. As the world becomes more conscious of environmental impact, manufacturers will be under pressure to produce products that are not only functional but also eco-friendly. We might see a rise in appliances made from recycled materials, and a greater emphasis on the recyclability of products at the end of their life cycle.

Personalization is another trend that’s likely to gain traction. Kitchen appliances could become more customizable, allowing users to tailor their appliances to their specific needs and preferences. This could range from adjustable settings on cooking appliances to modular designs that can be expanded or reconfigured as family needs change.

Health and wellness will also influence the future of kitchen appliances. There’s a growing demand for appliances that not only prepare food efficiently but also ensure its nutritional quality. For instance, ovens with steam cooking capabilities or blenders that offer nutrient extraction features could become standard. Additionally, appliances that can provide real-time data on food safety and quality will become increasingly important.

In terms of design, kitchen appliances are expected to become more integrated and less obtrusive. The lines between kitchenware and appliances will blur as multifunctional devices that serve both aesthetic and practical purposes become more common. Sleek, minimalist designs will likely become the norm, with a focus on space-saving and seamless integration into kitchen decor.

The rise of 3D printing could also have a significant impact on the kitchen appliance industry. Customization and rapid prototyping will become more accessible, allowing for the creation of appliances that are tailored to individual preferences and needs. This could lead to a more diverse range of products that cater to niche markets.

As we look ahead, the future of kitchen appliances seems to be one of continuous innovation and adaptation. Manufacturers will need to stay abreast of these trends to meet the evolving demands of consumers. The kitchen of tomorrow will be a place where technology and convenience meet sustainability and personalization, all while enhancing the culinary experience. Whether it’s through the development of new materials, the integration of cutting-edge technology, or the creation of appliances that cater to our health and well-being, the future holds a promise of a kitchen that is not just efficient but also an extension of our lifestyle.