Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving landscape of kitchen appliances, the quest for convenience and efficiency has led to groundbreaking innovations. As consumers, we find ourselves at the forefront of these advancements, constantly seeking the perfect blend of technology and practicality. Today, we delve into the realm of non-stick cookware, exploring the significance of LFGB compliance and the exciting developments shaping the future of our kitchens.

In recent years, the kitchen has transformed from a mere cooking space to a hub of innovation and technology. This shift is particularly evident in Europe and America, where smart kitchen appliances have surged in popularity. From smart ovens to induction cooktops, these gadgets are not just about convenience; they’re about revolutionizing how we interact with our culinary environments.

Europe, known for its culinary heritage and design sensibilities, has embraced smart kitchen appliances with open arms. The continent’s commitment to quality and sustainability has led to a market that values both efficiency and eco-friendliness. Smart dishwashers, for instance, are not only energy-efficient but also equipped with sensors that optimize water usage. European consumers are also drawn to appliances that integrate seamlessly into their homes, offering a blend of functionality and aesthetics.

In the United States, the trend towards smart kitchen appliances is driven by a different set of factors. The American market is characterized by its diversity and innovation, leading to a wide array of products that cater to different lifestyles. From high-tech countertop ovens that can mimic the perfect roast to refrigerators that can order groceries, the US consumer is spoiled for choice. The American kitchen has become a testament to the power of technology to enhance daily life.

The rise of smart kitchen appliances in both regions is not just a fad; it’s a reflection of broader societal changes. As people become more health-conscious, they seek appliances that can help them prepare nutritious meals with ease. Smart appliances often come with features like built-in recipe guides and nutritional tracking, making them an attractive option for those looking to improve their diet.

In Europe, the emphasis on sustainability is also reflected in the design and functionality of these appliances. For example, the German brand Miele offers smart kitchen appliances that are not only energy-efficient but also designed to last, reducing the need for frequent replacements. This focus on durability and sustainability resonates with consumers who are increasingly aware of their environmental footprint.

Similarly, in the US, companies like Whirlpool and GE are at the forefront of developing smart kitchen solutions that cater to the needs of the modern consumer. Their appliances are not only smart but also connected, allowing users to control them remotely via smartphones or tablets. This level of connectivity is particularly appealing to tech-savvy consumers who are always looking for ways to integrate technology into their daily routines.

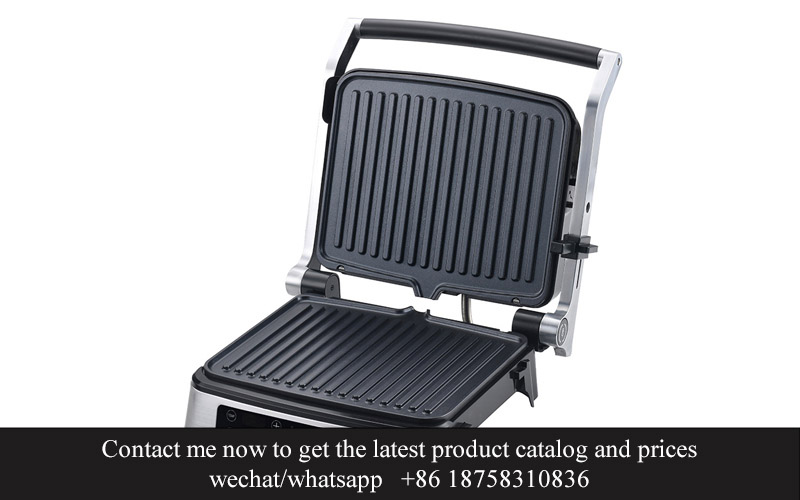

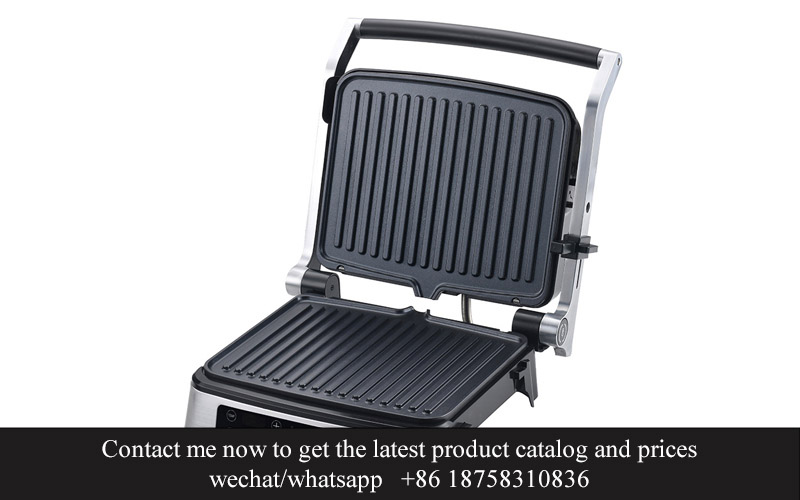

One cannot discuss the rise of smart kitchen appliances without mentioning the advancements in non-stick coating technology. In Europe and America, the demand for non-stick cookware has been growing, and this demand has spurred innovation. The introduction of LFGB-compliant non-stick coatings has been a game-changer, offering consumers a healthier and more durable alternative to traditional non-stick surfaces.

LFGB, which stands for Lebensmittel- und Futtermittelbestimmungen (Food and Feed Regulations), is a set of German regulations that ensure the safety and quality of food contact materials. LFGB-compliant non-stick coatings are free from harmful chemicals like PFOA and PTFE, which have been linked to health concerns. This has given consumers peace of mind, knowing that their appliances are not only smart but also safe.

The European market, with its stringent safety standards, has been quick to adopt LFGB-compliant non-stick coatings. Brands like Tefal and All-Clad have been at the forefront of offering cookware with these coatings, which are not only durable but also easy to clean. The American market, while less stringent in some aspects, has also seen a rise in the popularity of LFGB-compliant non-stick cookware, with consumers seeking out healthier options.

As the kitchen continues to evolve, the integration of smart features and LFGB-compliant non-stick coatings is setting new standards for the industry. The future of kitchen appliances in Europe and America looks promising, with a focus on innovation, safety, and sustainability. Whether it’s a smart oven that can simulate the perfect flame or a refrigerator that can keep track of your dietary needs, the smart kitchen is becoming a reality that promises to make cooking not just easier, but also more enjoyable and health-conscious.

In the ever-evolving landscape of kitchen appliances, the significance of non-stick coatings cannot be overstated. These coatings have become a staple in modern kitchens, not only for their convenience but also for their health and environmental benefits. Central to this transformation is the LFGB compliance, a set of stringent standards that ensure safety and quality.

The Lowenstein-Frankenthal-Gesundheitsamt (LFGB) regulations, adopted in Germany and often emulated internationally, are renowned for their rigorous approach to consumer protection. For kitchen appliance manufacturers, adhering to these standards is not just about meeting a legal requirement; it’s about building trust with customers who value their health and safety above all else.

Non-stick coatings that meet LFGB standards are free from harmful chemicals such as perfluorooctanoic acid (PFOA) and polytetrafluoroethylene (PTFE), which are associated with potential health risks. These chemicals can leach into food, particularly at high temperatures, and have been linked to various health issues. By opting for LFGB-compliant non-stick coatings, consumers can enjoy the ease of cooking without worrying about the potential risks of exposure to these substances.

Moreover, these coatings are designed to be durable and long-lasting. They are formulated to withstand high heat, making them perfect for searing, frying, and baking without the fear of peeling or chipping. This not only extends the life of the cookware but also reduces waste, which is a significant concern for environmentally conscious consumers.

In terms of user experience, LFGB-compliant non-stick coatings provide a smooth cooking surface that is incredibly easy to clean. This is a game-changer for busy individuals and families, who often struggle to find time for thorough cleaning after a long day. The non-stick quality means that food releases quickly, reducing the need for excessive oil or butter, which can be healthier and more economical.

For manufacturers, the benefits of LFGB compliance extend beyond customer satisfaction. These coatings are recognized worldwide, giving products a competitive edge in the global market. Customers who are aware of and demand LFGB-compliant products are likely to seek out brands that prioritize quality and safety.

Additionally, the use of LFGB-compliant non-stick coatings aligns with the growing trend towards sustainability. As consumers become more environmentally aware, they are gravitating towards products that are not only safe for their health but also for the planet. By choosing cookware with non-stick coatings that meet these standards, manufacturers can cater to this demand and contribute to a greener future.

Furthermore, the health benefits of LFGB-compliant non-stick coatings are not limited to the elimination of harmful chemicals. They also promote healthier cooking habits by reducing the amount of fat needed in recipes. This is particularly important for those following diets that focus on lower fat content, such as the Mediterranean diet or low-carb lifestyles.

The culinary industry is also reaping the rewards of these coatings. Chefs and professional cooks appreciate the ease and efficiency that non-stick coatings offer in their kitchens. The consistent performance and resistance to wear and tear mean that these coatings are ideal for the high demands of professional cooking environments.

In the realm of consumer electronics, the integration of smart features in kitchen appliances has been a game-changer. However, the success of these devices often hinges on the cookware they are paired with. LFGB-compliant non-stick coatings ensure that these smart kitchen appliances live up to their potential, providing a seamless cooking experience that combines innovation with safety.

Lastly, the global culinary scene is diverse, and with it comes a wide range of dietary preferences and restrictions. LFGB-compliant non-stick coatings cater to these variations, allowing people with specific dietary needs to enjoy a wide array of recipes without compromising on taste or safety.

In conclusion, the importance of LFGB-compliant non-stick coatings in the kitchen appliance industry cannot be overstated. They offer a multitude of benefits, from health and environmental safety to ease of use and cost-effectiveness. As consumers continue to prioritize quality and safety, and as the market evolves towards more sustainable and health-conscious options, LFGB-compliant non-stick coatings will undoubtedly play a pivotal role in shaping the future of cooking.

In the ever-evolving world of kitchen appliances, non-stick coatings have become a staple, making cooking easier and more enjoyable for millions. However, the market is not standing still, and there are several innovative advancements that are reshaping what’s new in the realm of non-stick technology.

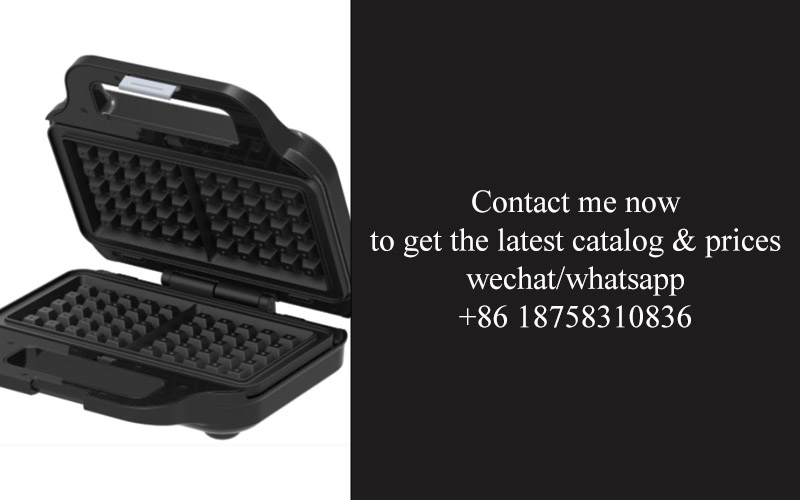

The first notable innovation is the introduction of ceramic non-stick coatings. Unlike traditional PTFE (Teflon) coatings, which can contain potentially harmful chemicals, ceramic coatings are made from natural minerals and are free from PFOA and PTFE. This not only makes them safer for health but also more durable. Users are now able to enjoy the ease of cooking with non-stick surfaces without the worry of toxic fumes when overheating.

Another breakthrough is the development of diamond-infused non-stick coatings. These coatings are engineered to provide an even harder surface than the traditional ceramic coatings, which means they are even more resistant to scratches and wear. The diamond particles are embedded into the coating, creating a superhydrophobic layer that not only prevents food from sticking but also makes cleaning a breeze.

Smart non-stick coatings are also making waves. These coatings are designed to be self-cleaning, using a unique blend of materials that create a surface that is both non-stick and self-cleaning. When heat is applied, the surface releases steam that helps to lift food particles away, making it easier to wipe off any residue. This technology is not only convenient but also energy-efficient, as it reduces the need for excessive cleaning chemicals and water.

The market has seen a surge in eco-friendly non-stick coatings. These coatings are designed to be more sustainable, with materials that are biodegradable and environmentally friendly. From plant-based resins to recycled metals, these coatings are a testament to the growing demand for eco-conscious products. Consumers who prioritize sustainability are now able to find non-stick cookware that aligns with their values without compromising on performance.

In terms of health and safety, there’s a new wave of coatings that are free from PFAS, a group of chemicals that have been linked to various health issues. These PFAS-free coatings offer the same non-stick benefits as traditional coatings but without the potential health risks. The shift towards PFAS-free alternatives is driven by consumer awareness and regulatory changes, ensuring that the cookware on our shelves is safer for both us and the planet.

One of the latest trends in non-stick technology is the integration of smart features. Cookware with built-in sensors, for example, can adjust the temperature to maintain the perfect cooking environment for various types of food. This not only makes cooking more precise but also extends the life of the non-stick coating by preventing overheating.

The market is also exploring the use of nanotechnology in non-stick coatings. Nanocoatings are incredibly thin and can be applied to a variety of materials, not just cookware. These coatings provide an ultra-smooth surface that is highly resistant to scratches and wear, making them ideal for everything from frying pans to non-stick bakeware.

Lastly, there’s a growing interest in the customization of non-stick coatings. Manufacturers are now offering a range of colors and finishes for non-stick cookware, allowing consumers to choose a style that complements their kitchen decor. This personalized approach to non-stick technology not only enhances the aesthetic appeal of kitchenware but also adds a touch of individuality to the cooking experience.

In conclusion, the non-stick technology market is constantly pushing boundaries with new innovations. From safer, more durable coatings to smart features and eco-friendly materials, the future of non-stick cookware is looking brighter and more versatile than ever before.

In today’s fast-paced world, convenience is king, and when it comes to cooking, non-stick coatings have become an indispensable part of kitchenware. But what sets apart a good non-stick pan from a great one? The answer often lies in LFGB compliance. Here’s why LFGB compliance matters to consumers and how it impacts the benefits they enjoy.

Non-stick coatings are designed to reduce the need for oil or butter when cooking, making it easier to cook healthier meals with less fat. However, not all non-stick coatings are created equal. LFGB-compliant non-stick coatings, certified by the German Food, Drug, and Cosmetic Act (Liegenschaftsfrei von Genussmitteln, Arzneimitteln und Kosmetika), offer a level of assurance that is hard to match.

One significant benefit of LFGB-compliant non-stick coatings is the peace of mind they provide. These coatings are free from harmful substances like PFOA (perfluorooctanoic acid) and PTFE (polytetrafluoroethylene), which have been associated with health risks in the past. By adhering to LFGB standards, manufacturers ensure that their products meet strict safety criteria, reducing the risk of consumers coming into contact with potentially harmful chemicals.

Consumers also appreciate the longevity and durability of LFGB-compliant non-stick coatings. These coatings are not only safe but also more resistant to wear and tear, meaning your pans will last longer and retain their non-stick properties for a greater number of cooking sessions. This not only saves money in the long run but also reduces the frequency of waste from outdated or worn-out cookware.

Another crucial aspect of LFGB-compliant non-stick coatings is their even heat distribution. These coatings are designed to ensure that heat is distributed evenly across the pan’s surface, leading to more consistent cooking results. This means your food will cook more evenly and avoid burning or sticking, which can be a common frustration with cheaper, non-certified non-stick coatings.

Ease of cleaning is another major selling point for LFGB-compliant non-stick cookware. The non-stick surface makes it effortless to wipe away residue, and food doesn’t stick to the pan as it would with traditional coatings. This not only saves time but also means that you can use less water and cleaning products, contributing to a more environmentally friendly kitchen routine.

For those who are health-conscious, LFGB-compliant non-stick coatings are a must-have. They allow for healthier cooking practices by reducing the amount of fat needed, which in turn can help lower cholesterol levels and contribute to a balanced diet. The ability to cook with less oil can also be particularly beneficial for individuals with dietary restrictions or those looking to monitor their calorie intake.

The benefits of LFGB-compliant non-stick coatings extend beyond health and convenience. They also cater to the aesthetic preferences of consumers. Modern cookware with these coatings often boasts a sleek, modern look that complements a variety of kitchen decor styles. The attractive appearance can be a significant factor in the decision-making process for many consumers who value the aesthetics of their kitchenware.

Moreover, LFGB compliance is not just about safety; it’s also about trust. When consumers see the LFGB logo on a product, they can trust that the manufacturer has gone through a rigorous certification process to ensure the quality and safety of the product. This trust is invaluable in an industry where misinformation and poor manufacturing practices can lead to consumer dissatisfaction.

In the realm of eco-conscious consumers, LFGB-compliant non-stick coatings also shine. These coatings are often more sustainable, as they are designed to last longer and reduce the need for frequent replacement. This not only minimizes waste but also supports the circular economy by extending the lifespan of products.

Lastly, the versatility of LFGB-compliant non-stick cookware is undeniable. Whether you’re searing steaks, sautéing vegetables, or simmering sauces, these pans can handle a wide range of cooking techniques. The non-stick surface means you can use non-stick pans for a variety of recipes without worrying about sticking or the need for excessive cleaning.

In conclusion, LFGB compliance in non-stick coatings is a crucial factor for consumers. It ensures safety, durability, even heat distribution, and ease of cleaning. It caters to health-conscious consumers, offers aesthetic appeal, builds trust, supports sustainability, and provides versatility in the kitchen. As the market continues to evolve, the importance of LFGB-compliant non-stick coatings will only grow, making them a standout choice for any home cook.

In today’s fast-paced world, the kitchen has evolved from a mere cooking space into a hub of innovation and convenience. Consumer choices are now influenced by a myriad of factors, with industry trends playing a pivotal role. These trends are not just shaping the way products are developed but also dictating what consumers prioritize in their purchases.

Health and Wellness: The demand for healthier lifestyles has surged, and this extends to kitchen appliances as well. Consumers are increasingly seeking products that are free from harmful chemicals and promote better health. Non-stick coatings, especially those compliant with the LFGB standard, are gaining popularity due to their ease of cleaning and ability to reduce the need for excessive oil, which in turn can lower the calorie content of meals.

Sustainability: Environmental concerns have led to a shift in consumer preferences towards sustainable products. The demand for appliances made from recyclable materials and those that are energy-efficient is on the rise. As manufacturers incorporate these sustainable practices into their non-stick coatings, consumers are more likely to choose brands that align with their values, even if it means a slightly higher price point.

Smart Technology Integration: The kitchen is no longer just a place for cooking; it’s becoming a smart, interconnected space. Consumers are drawn to non-stick coatings that are not only safe and easy to use but also compatible with smart kitchen systems. Features like temperature control and smart notifications can enhance the cooking experience and simplify the process, making the consumer’s life easier.

Aesthetic Appeal: With the kitchen often being a centerpiece in modern homes, the aesthetic appeal of appliances cannot be overlooked. Non-stick coatings are now available in a variety of colors and finishes, allowing consumers to personalize their kitchenware. This focus on design not only adds to the visual appeal of the kitchen but also reflects the consumer’s personal style and taste.

Functionality and Versatility: Consumers today are looking for kitchen appliances that can perform multiple tasks. Non-stick coatings that can be used on a range of cookware, from pans to bakeware, offer convenience and flexibility. The ability to use the same product for various cooking methods, such as frying, baking, and steaming, is highly valued, as it reduces the number of items needed in a kitchen and simplifies storage.

Safety and Compliance: Safety is paramount in kitchen appliances, and consumers are becoming more aware of the importance of compliance with international standards. LFGB compliance, which stands for the German Food, Tobacco, and Feedstuff Act, ensures that non-stick coatings are safe for food contact. This certification gives consumers peace of mind, knowing that the products they choose meet rigorous safety standards.

Brand Trust and Reputation: As consumers become more educated about the products they buy, they are also more likely to rely on brands with strong reputations. Companies that invest in research and development to create innovative non-stick coatings are more likely to gain consumer trust. This trust translates into loyal customer bases and a competitive edge in the market.

Marketing and Social Influence: The way brands market their products can significantly impact consumer choices. Influencers and chefs often showcase their favorite kitchen gadgets and tools, and their endorsements can sway consumer preferences. When these influencers emphasize the benefits of non-stick coatings that are LFGB compliant, it resonates with consumers who seek high-quality and safe products.

Economic Factors: Even as consumers prioritize health, sustainability, and technology, economic factors remain a consideration. Non-stick coatings that offer a balance between quality, performance, and affordability are more likely to be chosen over premium, high-tech options. This indicates that while industry trends are influential, cost remains a critical factor in consumer decisions.

Longevity and Durability: Consumers are not just interested in the immediate benefits of non-stick coatings but also in their longevity. A coating that withstands regular use and does not degrade quickly is more likely to be a preferred choice. This focus on durability is a testament to how consumers are looking for long-term value in their kitchen appliances.

The impact of industry trends on consumer choices is undeniable. As manufacturers continue to innovate and adapt to these trends, consumers will find themselves with more options than ever before. The key is for consumers to stay informed about the latest developments and to make choices that align with their personal needs and values.

In the realm of cookware, there are numerous success stories where LFGB-compliant non-stick coatings have made a significant impact. Let’s delve into a few case studies that showcase how these coatings have been successfully implemented and the benefits they bring.

In a bustling kitchenware store in Germany, the latest line of cookware featuring LFGB-compliant non-stick coatings caught the eye of many customers. These pans, with their sleek designs and impressive performance, quickly became a hit. Users praised the ease of cooking and the fact that cleaning was a breeze, thanks to the non-stick surface that required minimal oil.

A popular kitchenware brand in the United States decided to introduce LFGB-compliant non-stick coatings in their new range of cookware. The move was met with enthusiasm from consumers, who were already familiar with the brand’s commitment to quality. The cookware’s durability and the assurance of health standards, as guaranteed by the LFGB certification, became key selling points.

In a Scandinavian household, a family embraced LFGB-compliant non-stick coatings after experiencing issues with other cookware. The cookware’s eco-friendliness, due to the absence of harmful chemicals, was a significant draw. The family found that the non-stick surfaces held up over time, and the lack of stains or wear meant their cookware looked like new even after extended use.

A professional chef in Italy had been using LFGB-compliant non-stick coatings in his commercial kitchen for years. He praised the coatings for their excellent heat distribution, which allowed for consistent cooking temperatures. The non-stick properties also meant that the chef could work quickly without the risk of food sticking, saving time and effort in the busy kitchen environment.

In a health-conscious community in France, LFGB-compliant non-stick coatings were embraced for their safety and reliability. The coatings were free from PFOA, PTFE, and other harmful substances, which was a major concern for many consumers. The community appreciated the peace of mind that came with knowing their cookware was not only easy to use but also safe for their health.

A family in the Netherlands transitioned to LFGB-compliant non-stick coatings after being disappointed with previous cookware that wore down quickly. The cookware’s ability to withstand high temperatures without losing its non-stick qualities was a game-changer. The family also noticed that the coatings were more resistant to scratches, which prolonged the life of their cookware.

In the United Kingdom, a line of LFGB-compliant non-stick cookware was launched with a focus on sustainability. The brand aimed to reduce waste by creating cookware that could be recycled. The coatings, being eco-friendly, resonated with environmentally conscious consumers who appreciated the brand’s commitment to the planet.

In an Asian market, LFGB-compliant non-stick coatings were a hit with busy working professionals. The cookware’s convenience, ease of maintenance, and the assurance of health standards were appealing. Consumers loved the ability to cook a variety of dishes without the need for excessive oil, which was not only healthier but also saved them time and money.

These case studies highlight the diverse ways in which LFGB-compliant non-stick coatings have been successfully implemented in various markets. From individual households to professional kitchens, the benefits of these coatings are clear: they provide a safe, easy-to-use, and durable cooking experience that meets the highest health and safety standards.

In the ever-evolving world of cookware, non-stick technology has become a staple in modern kitchens. As consumer preferences shift and new materials emerge, the future of non-stick cookware is shaping up to be both innovative and sustainable. Here’s a glimpse into what we can expect:

The integration of eco-friendly materials is on the rise. With growing concerns about the environment, manufacturers are turning to alternative coatings that are free from harmful chemicals like PFOA and PTFE. These new eco-friendly coatings are designed to offer the same non-stick performance while being safer for both the cook and the planet.

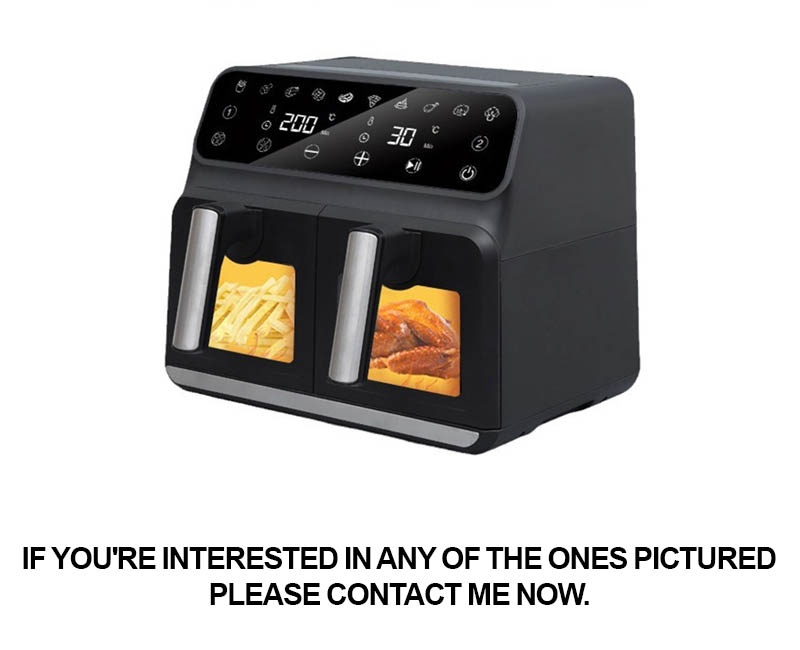

Smart cookware is becoming increasingly popular. The fusion of technology and cooking has led to the development of non-stick cookware that can connect to smartphones and smart home systems. Users can monitor cooking times, temperatures, and even receive recipe suggestions based on the type of food being prepared. This integration not only enhances the cooking experience but also promotes healthier eating habits.

Personalization is key. Customization options are becoming more accessible, allowing consumers to choose the color, size, and even the handle design of their non-stick cookware. This shift reflects a market that is becoming more consumer-centric, focusing on individual preferences and lifestyle needs.

The focus on durability is intensifying. Non-stick cookware that withstands the test of time is becoming a priority. New coatings are being developed to be more resistant to scratches, wear, and tear, ensuring that cookware remains effective and looks new for longer. This durability not only extends the lifespan of the product but also reduces waste.

Health and safety are paramount. As awareness of health risks associated with certain non-stick coatings grows, manufacturers are stepping up their game to ensure that their products meet the highest safety standards. This includes certifications like LFGB (German Food, Drug, and Cosmetics Act), which guarantees that the cookware is safe for food contact and free from harmful substances.

The rise of air fryers and other healthy cooking methods is influencing non-stick design. As consumers become more health-conscious, there’s a demand for cookware that can accommodate a variety of cooking techniques, including air frying, which uses little to no oil. Non-stick surfaces are perfect for these methods, making them a preferred choice for those looking to maintain a healthy diet.

Sustainability is a driving force. The future of non-stick cookware will likely see a greater emphasis on sustainability, from the sourcing of raw materials to the manufacturing process. Recyclable and biodegradable materials are being explored, and companies are looking for ways to reduce their carbon footprint throughout the product lifecycle.

Interactive features are becoming more sophisticated. Cookware with built-in sensors that can detect food temperature and cooking time is no longer a far-fetched idea. These features can provide real-time feedback, helping cooks achieve perfect results every time.

The market is becoming more inclusive. As the demand for non-stick cookware grows, so does the need for products that cater to diverse cooking styles and dietary restrictions. This includes cookware that is suitable for gluten-free, vegan, and other specialized diets.

The future of non-stick cookware is bright and diverse. It’s a market that is responding to consumer needs, technological advancements, and environmental concerns. Whether it’s through eco-friendly materials, smart features, or a focus on health and safety, the future holds exciting possibilities for those who love to cook.

In the evolving landscape of kitchen appliances, the integration of smart technology and health-conscious designs has become increasingly pivotal. As consumers seek out products that not only enhance their cooking experience but also prioritize their well-being, the demand for LFGB-compliant non-stick coatings has surged. These coatings, adhering to the stringent German Food, Drug, and Cosmetic Act (LFGB), offer a blend of convenience, safety, and eco-friendliness. Let’s delve into the specifics of how these coatings are reshaping the future of non-stick cookware.

Non-stick coatings have long been a staple in kitchenware, providing a seamless cooking surface that reduces the need for excessive oil or butter. However, as environmental concerns and health awareness have grown, so has the demand for more sustainable and safer alternatives. LFGB-compliant non-stick coatings stand out for their adherence to strict quality standards, ensuring that the cookware they grace is not just effective but also safe for regular use.

One significant innovation in non-stick technology is the development of ceramic coatings. These coatings are made from natural, non-toxic materials, offering a healthier alternative to traditional PTFE (Teflon) coatings. Ceramic coatings are durable, heat-resistant, and do not release harmful fumes at high temperatures, making them a favorite among health-conscious consumers. Their ease of cleaning and longevity have also contributed to their popularity.

Another area of innovation lies in the application process of these coatings. Advanced spray techniques have allowed manufacturers to apply non-stick coatings more evenly and thinly, resulting in a superior non-stick surface that is also more durable. This technological advancement ensures that the coating withstands the rigors of daily use without peeling or flaking, a common issue with older non-stick coatings.

The rise of smart kitchen appliances has also influenced the development of non-stick coatings. Many modern cookware sets now come with features like temperature control and smart sensors that prevent overcooking and burning. These innovations are often complemented by LFGB-compliant non-stick coatings, which provide a safe cooking surface that can handle the increased temperatures and cooking times required by these smart features.

Consumer benefits are at the heart of these advancements. LFGB-compliant non-stick coatings offer several key advantages:

Health and Safety: The non-toxic nature of these coatings ensures that no harmful chemicals leach into food, making them a safer option for cooking and serving meals.

Ease of Cleaning: The non-stick surface reduces the need for scrubbing, which not only saves time and effort but also preserves the integrity of the cookware.

Eco-Friendly: As more consumers become environmentally conscious, the use of sustainable materials in non-stick coatings aligns with their values, promoting a greener kitchen.

Durability: The improved quality of non-stick coatings means that cookware can last longer, reducing the need for frequent replacements and the associated environmental impact.

Case studies have highlighted the success of LFGB-compliant non-stick coatings in the market. For instance, a popular brand has seen a significant increase in sales after introducing a line of cookware with these coatings. The brand’s commitment to quality and health has resonated with consumers, who appreciate the peace of mind that comes with using products that meet such rigorous standards.

Looking ahead, the future of non-stick cookware appears promising. As technology continues to advance, we can expect to see even more innovative coatings that offer enhanced performance, durability, and safety. Nanotechnology is already being explored to create coatings that are even more heat-resistant and non-stick. Additionally, there is a growing trend towards biodegradable and compostable materials, which could further reduce the environmental footprint of non-stick cookware.

In conclusion, the integration of LFGB-compliant non-stick coatings into kitchen appliances represents a significant step forward in the industry. These coatings not only provide consumers with a healthier, more sustainable cooking experience but also align with the broader trends of smart technology and environmental responsibility. As we navigate the smart kitchen of the future, it’s clear that these coatings will play a pivotal role in shaping the landscape of cookware, offering a path to a safer, more efficient, and eco-friendly culinary domain.