Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where culinary innovation meets health consciousness, the air fryer has emerged as a game-changer in the kitchen appliance industry. This compact yet powerful device has captured the attention of both consumers and manufacturers alike, and with the rise of OEM (Original Equipment Manufacturer) services, the possibilities for customization and efficiency are endless. As we delve into the unique ideas and trends shaping the future of air fryer products, it’s clear that the industry is on the brink of a revolutionary transformation.

The air fryer, once a niche appliance, has soared in popularity as consumers embrace health-conscious cooking methods. This surge in demand isn’t just a fleeting trend; it’s a testament to the changing landscape of culinary preferences. As we delve into the world of health and wellness, the OEM air fryer has emerged as a star player, offering a solution that marries flavor with fitness.

Health consciousness is not a new concept, but its influence on consumer choices has grown exponentially. With the rise of social media and health influencers, the desire for nutritious, yet delicious meals has become more accessible than ever. The air fryer, with its promise of crispy, fried foods with a fraction of the fat, has quickly become a staple in kitchens around the globe.

The convenience of the air fryer is undeniable. Its compact design means it can fit into any kitchen space, from a cozy apartment to a sprawling household. The cooking process is also a breeze, typically requiring just a few minutes to prepare and cook your favorite dishes. This ease of use, coupled with its health benefits, has propelled the air fryer into the mainstream.

But it’s not just the consumer who has taken notice. Manufacturers have jumped on the bandwagon, recognizing the potential for innovation in this burgeoning market. Enter the OEM air fryer, a product designed by one company but manufactured and sold under another’s brand. This model allows brands to offer a cutting-edge appliance without the steep investment in research and development.

One of the key advantages of the OEM air fryer is customization. With the mold-making service, brands can create air fryers that not only meet their specific design and performance requirements but also resonate with their target audience. Imagine a sleek, modern air fryer with an ergonomic handle, or one that features smart technology for precise temperature control. The possibilities are endless, and the mold-making service makes these visions a reality.

The health benefits of air frying are clear. Traditional deep-frying involves submerging food in hot oil, which can lead to the absorption of excess fat. Air frying, on the other hand, circulates hot air around the food, creating a crispy exterior with minimal oil. This not only reduces the calorie content of your favorite fried foods but also minimizes the risk of heart disease and other health issues associated with excessive oil consumption.

Another aspect that has driven the popularity of air fryers is the variety of recipes available. From crispy French fries to golden-brown chicken wings, the air fryer can replicate the flavors and textures of fried foods without the guilt. This versatility has made it a favorite among those looking to enjoy their favorite treats while maintaining a balanced diet.

Moreover, the environmental benefits of air frying are noteworthy. By reducing the need for large quantities of cooking oil, air fryers contribute to a lower carbon footprint. This eco-friendly approach aligns with the growing movement towards sustainability, making the OEM air fryer an attractive option for consumers who are both health-conscious and environmentally aware.

As the market for air fryers continues to expand, innovation remains key. Manufacturers are constantly pushing the boundaries, developing new features and capabilities. One such innovation is the ability to integrate the air fryer with other kitchen appliances, such as ovens or refrigerators, to create a seamless and efficient cooking experience.

The mold-making service plays a crucial role in this innovation process. It allows manufacturers to create custom molds that can produce air fryers with unique shapes, sizes, and functionalities. Whether it’s a model with a built-in timer, a digital display, or a non-stick coating, the mold-making service ensures that these features are seamlessly integrated into the final product.

In conclusion, the rise of the health-conscious consumer has led to a surge in demand for appliances that can provide delicious, nutritious meals. The OEM air fryer, with its mold-making service, offers a perfect solution for brands looking to capitalize on this trend. By combining customization, health benefits, and environmental consciousness, the OEM air fryer is not just a cooking appliance; it’s a symbol of the future of kitchen technology.

In the world of kitchen appliances, the demand for healthier cooking solutions has surged, and the air fryer has emerged as a star player. To cater to this growing trend, the mold making service for OEM air fryers has become a crucial component in bringing innovative designs to life. Here’s a closer look at how this service is revolutionizing the industry.

Mold making is an art form, blending precision engineering with creativity. For air fryers, these molds are the foundation upon which the future of kitchen gadgets is built. They are the intricate templates that shape the plastic parts that make up the fryer’s body, ensuring that each unit is not just functional but also aesthetically pleasing.

The process begins with a thorough design phase, where engineers and designers work together to conceptualize an air fryer that not only meets consumer expectations for health and convenience but also stands out in a crowded market. Each design must consider factors like ease of use, energy efficiency, and the ability to produce crispy, delicious results without the excess oil that traditional deep-frying requires.

Once the design is finalized, the mold making service steps in. This service is not just about creating molds; it’s about crafting the molds with such precision that the final product is seamless and durable. The molds are typically made from high-quality materials like steel or aluminum, which are known for their strength and the ability to withstand the rigorous demands of mass production.

The mold making process itself is a delicate balance of science and craftsmanship. It involves the use of advanced CNC machines, which cut intricate patterns into the mold material. These patterns are the blueprint for the air fryer’s shape and structure, ensuring that every part fits perfectly together.

One of the key advantages of this service is the ability to customize. OEM customers can work closely with mold makers to create a fryer that reflects their brand’s identity and meets specific market needs. Whether it’s a unique handle design, a particular size, or even a specialized feature like a built-in timer, the mold making service can accommodate these requests.

Quality control is paramount in mold making. Each mold is subjected to rigorous testing to ensure that it can withstand the high temperatures and pressures of the injection molding process. This ensures that the final product is free from defects and maintains the highest standards of quality.

The mold making service also plays a vital role in reducing production costs. By creating molds that are efficient and durable, manufacturers can produce air fryers at a lower cost without compromising on quality. This cost-effectiveness is passed on to the consumer, making high-quality air fryers more accessible.

Innovation is at the heart of the mold making service. As new materials and technologies emerge, mold makers are quick to adapt. For example, the use of biodegradable materials in mold making is gaining traction, reflecting a broader industry trend towards sustainability.

The complexity of modern air fryers also means that mold making services must keep up with technological advancements. The introduction of smart features requires molds that can accommodate intricate electronic components, ensuring that the fryer is not only functional but also smart and connected.

The mold making service is not just about creating a mold; it’s about creating a solution. It’s about taking a design from concept to reality, ensuring that every air fryer that rolls off the assembly line is a testament to the power of innovation and the importance of detail.

As the demand for health-conscious cooking continues to rise, the role of the mold making service in the OEM air fryer industry becomes even more significant. It’s not just about making a fryer; it’s about making a difference in how people cook and live. By providing tailor-made molds, the service is not just shaping the air fryer of today but also paving the way for the appliances of the future.

The European and American kitchen appliance industry has undergone a significant transformation, driven by changing consumer preferences and technological advancements. To navigate this dynamic market, understanding the current trends and data is crucial for businesses looking to thrive.

Consumer Preferences Shift Towards SustainabilityThere’s a growing emphasis on sustainability in kitchen appliances, with consumers increasingly seeking eco-friendly options. Energy-efficient models and those made from recycled materials are gaining popularity, reflecting a broader shift towards environmentally conscious choices.

Smart Kitchen Technology Gaining TractionSmart kitchen appliances are becoming more common, with a focus on connectivity and integration with home automation systems. In the European market, particularly, there’s a strong interest in appliances that offer remote control and monitoring via smartphones or tablets. The American market, while similar, also shows a preference for voice-activated devices compatible with popular smart assistants like Amazon Alexa and Google Home.

Health and Wellness Trends Influence Appliance DesignHealth-conscious consumers are driving the design of kitchen appliances. For example, air fryers have seen a surge in popularity due to their ability to cook with less oil, aligning with a broader interest in healthy cooking methods. The market for slow cookers and pressure cookers has also increased as they offer convenient and nutritious meal options.

Market Size and Growth ProjectionsIn Europe, the kitchen appliance market is projected to grow at a steady pace, with Germany, the UK, and France being the largest markets. The United States kitchen appliance market is also expected to see modest growth, driven by a high disposable income and a culture of home improvement and entertaining.

E-commerce’s Impact on the IndustryThe rise of e-commerce has changed how consumers purchase kitchen appliances. Online sales are becoming a significant portion of total sales, with more consumers turning to online reviews and detailed product information to inform their buying decisions. This shift has prompted manufacturers to adapt their marketing strategies and ensure their online presence is robust.

Regional Variations in Consumer BehaviorWhile there are overarching trends, there are notable regional variations in the kitchen appliance industry. For instance, in Germany, there’s a strong preference for high-quality, durable appliances, while in Italy, there’s a focus on style and aesthetics. The American market, on the other hand, has a diverse range of preferences, from traditional to modern, reflecting the country’s cultural and demographic diversity.

Innovation in Materials and ConstructionInnovation isn’t just about technology; it’s also about materials and construction. There’s a trend towards using advanced materials that improve durability, such as reinforced plastic in blender bodies or stainless steel in cooktops. These materials not only enhance performance but also contribute to the overall appeal of the appliance.

Energy Regulations and CertificationEnergy efficiency is a key concern for consumers and regulators alike. In Europe, the Energy Label has been a significant driver in promoting energy-efficient appliances. The same is true in the United States, where the Energy Star certification is a benchmark for energy efficiency. Manufacturers must stay informed about these regulations to remain competitive.

The Importance of After-Sales ServiceAs appliances become more complex, after-sales service has become a critical factor in consumer satisfaction. Brands that offer comprehensive warranty coverage and easy access to parts and service are more likely to retain customers and build loyalty.

The kitchen appliance industry in Europe and America is complex, with numerous factors influencing market trends. By understanding these trends and data, companies can better position their products, adapt to consumer needs, and capitalize on the opportunities presented by this evolving market landscape.

In the world of kitchen appliances, the demand for efficiency and customization has reached new heights. OEM air fryers have emerged as a game-changer, offering a perfect blend of both. Let’s delve into the numerous benefits that these tailored appliances bring to the table.

The first advantage is the unparalleled customization options they provide. OEM air fryers are not just mass-produced units; they are crafted to suit the specific needs and preferences of individual customers. This means that businesses can have air fryers that are not only designed to their brand identity but also to their exact specifications, from size and capacity to features and functionalities.

Efficiency is at the heart of OEM air fryers. These appliances are engineered to maximize energy usage while minimizing waste. The advanced technology ensures that food is cooked to perfection with minimal oil, which not only reduces the calorie content but also cuts down on cleanup time. This is particularly appealing to health-conscious consumers who are looking for healthier cooking alternatives.

One of the standout benefits of OEM air fryers is their versatility. They can handle a wide range of recipes, from crispy French fries to juicy chicken wings, all with the same appliance. This versatility is a huge plus for busy households and commercial kitchens alike, as it eliminates the need for multiple cooking devices.

The design of OEM air fryers often incorporates user-friendly features that enhance the cooking experience. From intuitive digital controls to programmable settings, these appliances make it easy for users to achieve consistent results every time. This not only simplifies the cooking process but also ensures that even those who are new to air frying can enjoy the benefits of this technology.

In terms of cost-effectiveness, OEM air fryers offer significant savings. They are designed to be energy-efficient, which means they consume less electricity than traditional frying methods. Over time, this can lead to substantial cost savings, both for consumers and for businesses that rely on these appliances for their operations.

Another benefit is the environmental impact. By using less oil and requiring less energy, OEM air fryers contribute to a greener planet. The reduced oil usage also means less waste, which is a concern for many environmentally conscious consumers.

The market for OEM air fryers is also driven by the growing popularity of healthier lifestyles. With an increasing number of people looking to reduce their intake of unhealthy fats and calories, air fryers have become a staple in many kitchens. OEM models allow businesses to cater to this demand by offering products that are both healthy and convenient.

OEM air fryers also offer the flexibility to integrate various technologies. For example, some models come with features like a built-in timer, temperature control, and even a dehydrating function. This means that they can be used for a variety of cooking tasks, making them a versatile addition to any kitchen.

The quality of materials used in OEM air fryers is another key benefit. High-quality components ensure durability and longevity, which is important for both consumers and businesses. These appliances are built to last, providing years of reliable service.

Lastly, the competitive pricing of OEM air fryers makes them an attractive option for a wide range of customers. They offer premium features at a more accessible price point, making them a compelling choice for those looking to upgrade their kitchen appliances without breaking the bank.

In conclusion, the benefits of OEM air fryers are multifaceted, offering customization, efficiency, versatility, user-friendliness, cost-effectiveness, environmental benefits, and competitive pricing. These appliances are not just a trend; they are a testament to how technology can enhance our daily lives, one meal at a time.

In the ever-evolving landscape of kitchen appliances, air fryers have emerged not just as a trend but as a game-changer in healthy cooking. As we delve into the realm of OEM air fryers, it’s crucial to explore the innovative ideas that are not only shaping the present but also paving the way for the future. From smart features to eco-friendly designs, here are some unique concepts that are redefining the air fryer market.

The integration of smart technology is a cornerstone in the design of future air fryer products. Imagine an air fryer that not only cooks your food but also syncs with your smartphone, allowing you to monitor and control the cooking process remotely. Features like temperature control and automatic shut-off when the cooking is complete are not just conveniences; they are safety measures that bring peace of mind to the user.

Eco-conscious consumers are increasingly seeking appliances that align with their environmental values. Air fryers that are made from recycled materials or are designed for easy disassembly and recycling are not just trendy; they’re a testament to the industry’s commitment to sustainability. The idea of a fully biodegradable air fryer, for instance, is not far-fetched, as companies are exploring materials that can reduce the carbon footprint without compromising on performance.

Functionality has always been a key driver in the kitchen appliance market, and air fryers are no exception. One unique idea is the development of air fryers with built-in timers and smart recipes. These appliances could come pre-programmed with a variety of recipes, from crispy French fries to succulent chicken breasts, with the timer adjusting the cooking time and temperature accordingly. This not only simplifies cooking but also ensures that the end result is consistently delicious.

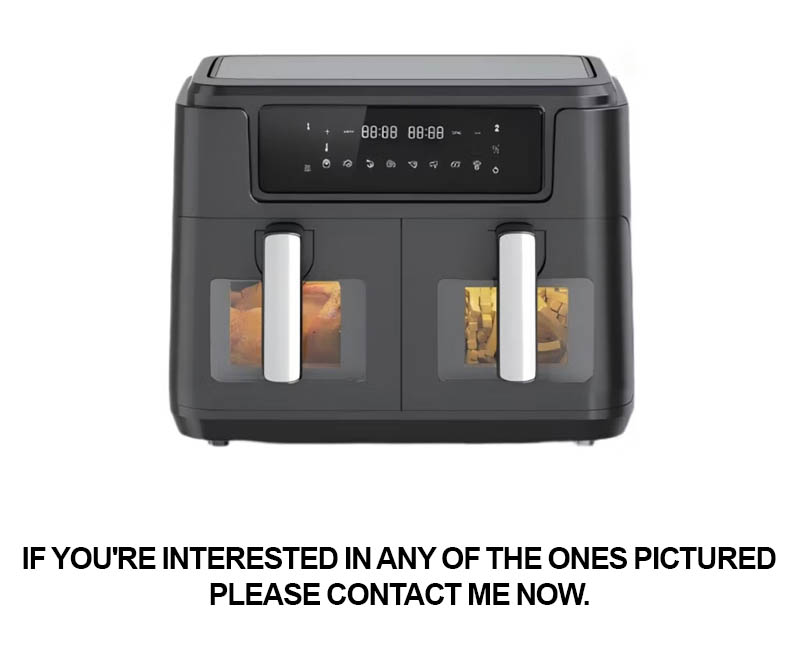

The concept of modular air fryers is also gaining traction. These are air fryers that can be customized with different attachments, allowing users to transform their appliance into a multi-functional cooking station. Imagine having an air fryer that can be swapped with a dehydrator attachment for making healthy snacks or a rotisserie for roasting meats. This modular approach not only saves space but also encourages creativity in the kitchen.

Another innovative idea is the incorporation of a built-in air filtration system. As air fryers circulate hot air around the food, they also recirculate the oil used in the cooking process. An air fryer with a filtration system could trap and remove excess oil particles, making the air cleaner and potentially reducing the risk of oil buildup in the appliance itself.

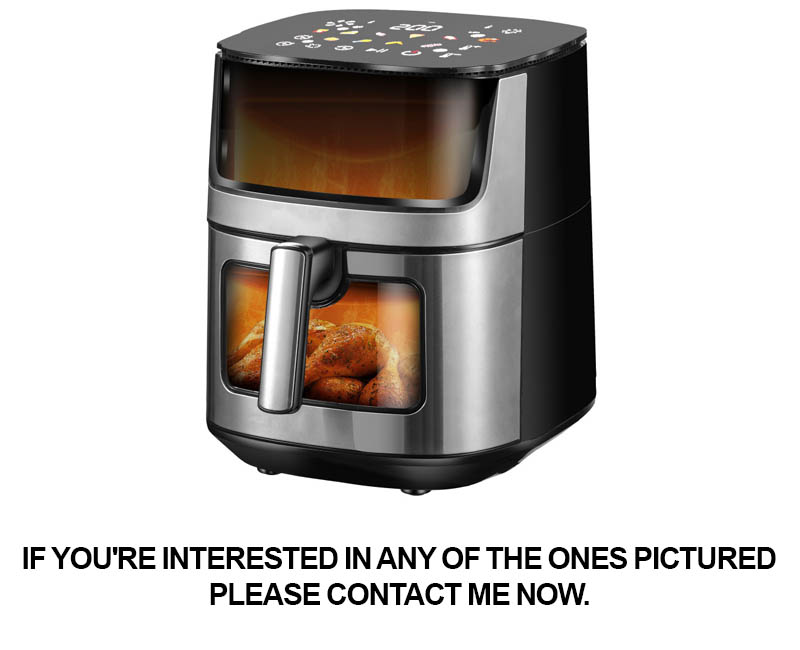

The aesthetic appeal of an air fryer should not be overlooked. Designers are exploring sleek, minimalist designs that not only match modern kitchen aesthetics but also make the appliance a centerpiece of the kitchen. Think of an air fryer with a glass door, allowing you to watch your food cook without opening the appliance, thus maintaining the internal temperature and reducing cooking time.

Innovation also extends to the user interface. Touchscreen controls with intuitive interfaces are becoming standard, but the next step could be voice-activated controls. Users could simply speak their desired settings, making the cooking experience even more hands-free and accessible.

Safety features are always a priority, and air fryers are no different. The inclusion of smart sensors that detect food readiness and automatically turn off the appliance is a significant step towards preventing fires and accidents. Additionally, air fryers could be designed with non-slip bases and cool-touch handles to prevent burns and make them safer to use.

Lastly, the idea of an air fryer that is adaptable to different power sources is intriguing. Whether you’re at home, on a camping trip, or in a remote location, an air fryer that can be powered by solar panels or a portable battery could be a game-changer for those who are always on the move.

These unique ideas for air fryer products are not just about adding new features; they’re about enhancing the user experience, making cooking healthier, more efficient, and more enjoyable. As the industry continues to innovate, the future of air fryers looks bright and full of possibilities.

In the fast-paced world of kitchen appliance manufacturing, the importance of collaboration with industry experts cannot be overstated. Our mold making service is a cornerstone of this partnership, providing invaluable support that enhances the quality and efficiency of air fryer products. Here’s how we add value at every step:

Our team of mold making experts brings years of experience to the table, ensuring that the molds we create are not only precise but also optimized for the most demanding production environments. The expertise in material science and design allows us to produce molds that withstand high temperatures and pressures, crucial for the air frying process.

The precision of our molds is paramount. Every curve and crevice must be meticulously crafted to ensure the air fryer’s internal components fit perfectly, promoting even cooking and preventing any leaks or malfunctions. This attention to detail is what sets our molds apart, leading to longer-lasting and more reliable products.

Customization is at the heart of our mold making service. We understand that each client has unique needs, whether it’s a specific size, shape, or functionality for their air fryer. Our ability to tailor molds to these specifications means that our clients can bring their innovative ideas to life, staying ahead of the competition in a rapidly evolving market.

Efficiency is a key driver in our mold making process. We utilize advanced manufacturing techniques and cutting-edge equipment to reduce production times without compromising quality. This means our clients can get their products to market faster, capitalizing on the latest trends and consumer demands.

Quality assurance is woven into the fabric of our mold making service. We perform rigorous testing on each mold to ensure it meets the highest industry standards. This includes stress tests, durability checks, and performance evaluations. Our commitment to quality means that the air fryers our clients produce will be of the highest caliber.

Collaboration with industry experts extends beyond the mold making process. We work closely with our clients to understand their production processes and identify areas for improvement. By analyzing their assembly lines and identifying potential bottlenecks, we can suggest modifications to the molds that not only enhance efficiency but also reduce waste.

Our mold making service is not just about creating a physical product; it’s about creating a partnership that fosters innovation. We encourage our clients to share their ideas for new features or design changes, and we turn these ideas into tangible improvements. This collaborative approach means that our clients are not just receiving a mold; they’re getting a strategic advantage in the market.

Innovation is a continuous process, and our mold making service is designed to adapt to these changes. As new materials and technologies emerge, we stay at the forefront, ensuring that our molds are compatible with these advancements. This adaptability means that our clients can confidently invest in long-term relationships with us, knowing that we will be there to support their future endeavors.

The value of our mold making service is also reflected in the cost-effectiveness we offer. By optimizing the design and production of molds, we help our clients reduce costs without sacrificing quality. This cost savings is passed on to the end consumer, making the air fryers more accessible and competitive in the market.

Our focus on sustainability is another aspect that adds value to our mold making service. We are committed to using eco-friendly materials and practices in our manufacturing process. This not only aligns with the growing demand for sustainable products but also helps our clients meet their environmental goals and appeal to environmentally conscious consumers.

In conclusion, our mold making service is more than just a component of the manufacturing process; it’s a strategic partner that helps our clients achieve their goals. By combining industry expertise, precision, customization, efficiency, and a commitment to quality and innovation, we add significant value to the air fryer products our clients bring to market.

In the fast-paced world of consumer electronics, the journey from an initial concept to a market-ready product is a symphony of innovation, precision, and collaboration. This process is particularly intriguing in the realm of air fryers, where cutting-edge technology meets culinary efficiency. Let’s delve into the intricacies of transforming a simple idea into a sleek, functional, and sought-after kitchen appliance.

The inception of a new air fryer concept often begins with a deep dive into market research. Design teams analyze consumer trends, identifying gaps in the current market offerings. This could range from exploring the desire for healthier cooking methods to understanding the growing preference for kitchen appliances that are compact, easy to use, and aesthetically pleasing.

Once a concept is chosen, the brainstorming session kicks off, with engineers, designers, and marketing experts pooling their ideas. This collaborative effort often results in a series of sketches and prototypes that begin to take shape. The team meticulously considers factors like ease of use, safety features, energy efficiency, and, of course, the desired cooking performance.

The next step involves the creation of a working prototype. This isn’t just a rough model; it’s a fully functional unit that embodies the core features of the final product. This prototype is tested extensively to ensure that all components work harmoniously and that the design can withstand the rigors of everyday use.

Material selection is critical in the air fryer’s development. Materials must be not only durable and heat-resistant but also safe for food contact and environmentally friendly. Advanced materials like stainless steel for the exterior, non-stick coatings for the basket, and high-quality plastics for internal components are chosen for their longevity and health benefits.

With the prototype in hand, the testing phase begins in earnest. Engineers subject the air fryer to a battery of tests to gauge its performance, safety, and reliability. These tests include cooking various types of food to ensure even heating, drop tests to simulate accidental drops, and endurance tests to ensure the appliance can handle continuous use.

Feedback from initial testing is invaluable, as it guides the next round of improvements. The design may be refined, and new components may be integrated. This iterative process continues until the air fryer meets all the required standards and exceeds consumer expectations.

Simultaneously, the marketing and branding team are at work, developing the product’s identity and messaging. They create a narrative around the air fryer, highlighting its unique selling points and how it fits into the busy lives of modern consumers. This branding is essential in setting the product apart from the competition.

As the product nears completion, it moves into the production phase. This involves setting up a manufacturing line that can produce the air fryer in high volumes while maintaining the same quality standards as the prototype. Quality assurance protocols are put in place to ensure that every unit that leaves the factory meets the high standards set by the design team.

Packaging design is also a crucial aspect of the final product. The packaging not only needs to protect the air fryer during transit but also needs to communicate the product’s features and benefits clearly. It should be attractive enough to catch the consumer’s eye on the shelf but also functional, ensuring that the product can be easily opened and used.

Finally, the product is ready for market launch. This is where the marketing and sales teams step in to create a buzz around the new air fryer. They develop a marketing strategy that includes online and offline promotions, influencer partnerships, and potentially even a launch event. The goal is to generate excitement and create a demand for the product.

The journey from concept to market-ready air fryer is a testament to the power of innovation and the importance of attention to detail. It’s a process that requires creativity, precision, and a deep understanding of both the technology and the consumer’s needs. In the end, the result is a product that not only meets but exceeds expectations, making a significant impact in the kitchen appliance industry.

In the world of OEM air fryer solutions, there are numerous success stories that highlight the transformative impact of our services. From startups to established brands, these case studies showcase how our expertise in air fryer design, manufacturing, and customization has led to market-ready products that resonate with consumers. Let’s delve into a few of these compelling stories.

Story 1: The Eco-Friendly StartupA small startup with a mission to create sustainable kitchen appliances approached us with a vision for an eco-friendly air fryer. The team had a concept that incorporated recycled materials and innovative energy-saving features. Our mold making service was tasked with creating a mold that would produce an air fryer with a sleek, modern design while being environmentally conscious. The end result was a product that not only met the startup’s sustainability goals but also exceeded consumer expectations, leading to a strong market reception and a growing customer base.

Story 2: The Tech Giant’s Market ExpansionA global tech giant was looking to expand into the kitchen appliance market with a line of smart kitchen gadgets. The company’s research indicated a growing interest in air fryers, but they needed a product that could stand out in a crowded market. Our mold making service worked closely with the design team to develop a mold for an air fryer that not only looked innovative but also integrated advanced technology. The final product featured a touch screen interface, voice control, and a unique, modular design that allowed for easy customization. This innovative air fryer became a flagship product for the tech giant, driving sales and establishing the brand as a leader in smart kitchen solutions.

Story 3: The Health-Conscious BrandA well-known health-focused brand wanted to introduce a new air fryer to their product line that would cater to customers looking for healthier cooking options. The challenge was to create a product that not only cooked food efficiently but also looked appealing and was easy to use. Our mold making service crafted a mold for an air fryer with a compact, space-saving design and a user-friendly interface. The result was a sleek, modern air fryer that received glowing reviews from customers, who appreciated its health benefits and convenience. The brand’s market share in the health-conscious segment grew significantly as a result.

Story 4: The Budget-Friendly LineA mid-tier appliance manufacturer sought to create a line of budget-friendly air fryers that would appeal to a wide range of consumers. The goal was to produce a high-quality product at an affordable price point. Our mold making service was instrumental in creating a mold that allowed for mass production without compromising on quality. The final product was a durable, efficient air fryer that offered a range of cooking functions at a fraction of the cost of premium models. This success story helped the manufacturer establish a strong presence in the budget kitchen appliance market.

Story 5: The Customizable Air FryerA custom kitchen appliance company wanted to offer a personalized air fryer experience to their clients. They approached us with the idea of creating a mold that would allow for customizable air fryers, with clients able to choose from various colors, sizes, and features. Our mold making service developed a flexible mold system that could accommodate these customizations. The result was a line of air fryers that became a hit with consumers looking for a unique kitchen appliance that reflected their personal style.

Story 6: The Cross-Platform IntegrationA company specializing in cross-platform kitchen appliances wanted to integrate their air fryer with smart home technology. Our mold making service was involved in creating a mold that would allow for seamless integration with various smart devices. The final product was an air fryer that could be controlled via a smartphone app, offering users the convenience of cooking from anywhere. This innovative approach to kitchen appliances helped the company carve out a niche in the smart kitchen market.

These case studies demonstrate the value our mold making service brings to the OEM air fryer industry. By collaborating with industry experts, we help turn concepts into market-ready products that not only meet consumer demands but also push the boundaries of what’s possible in kitchen appliance design and technology.

In today’s fast-paced world, the demand for efficient and innovative kitchen appliances has surged. Among these, air fryers have emerged as a game-changer, offering a healthier alternative to traditional frying methods. When it comes to meeting this demand, the choice of mold making service can be the difference between a standard product and a market leader. Here’s why selecting our mold making service for your air fryer needs is a strategic move.

Our mold making service is not just about creating a mold; it’s about crafting the foundation for a product that stands out in the competitive landscape. We understand that every detail matters, from the intricate design to the durability of the mold itself. Let’s delve into the reasons why our service is the right choice for your air fryer projects.

Precision and QualityThe precision of a mold is crucial in ensuring that the air fryers we produce are of the highest quality. Our state-of-the-art facilities are equipped with cutting-edge technology that allows us to create molds with tolerances as tight as 0.01mm. This level of precision ensures that the air fryers we help produce fit perfectly, function smoothly, and maintain their structural integrity over time.

Customization at Its BestEvery brand has its unique identity, and our mold making service is designed to reflect that. We offer a wide range of customization options, from the shape and size of the air fryer to the specific features that set your product apart. Whether you’re looking for a compact model for single-use or a large-capacity unit for commercial kitchens, our team works closely with you to ensure that the mold design aligns with your brand’s vision.

Rapid Prototyping and DevelopmentTime is of the essence in the appliance industry. Our mold making service includes rapid prototyping capabilities, allowing us to quickly turn your design into a tangible product. This means you can bring your air fryer to market faster, staying ahead of the competition. Our efficient process minimizes lead times without compromising on quality, ensuring that your product meets the highest standards.

Cost-Effective SolutionsWhile quality is paramount, cost-effectiveness is equally important. We pride ourselves on offering cost-effective mold making solutions without sacrificing the durability or performance of the final product. Our in-house expertise and streamlined production processes help us reduce costs without compromising on the quality of the molds we produce.

Innovation and SustainabilityThe world is moving towards more sustainable practices, and our mold making service is no exception. We use eco-friendly materials and processes that are not only kind to the environment but also contribute to the longevity of the molds. This commitment to sustainability is reflected in the quality of the air fryers we help produce, ensuring they are not only efficient but also environmentally responsible.

Expertise in MaterialsChoosing the right material for your air fryer mold is critical. We have extensive experience with various materials, including stainless steel, aluminum, and plastic, each offering different benefits. Our team of experts can advise you on the best material for your specific application, ensuring that your air fryer is not only functional but also aesthetically pleasing.

Global Reach and SupportOur mold making service is not limited to a single region. We have a global presence, allowing us to support clients from all corners of the world. Whether you’re a small startup or a large multinational corporation, we offer the same level of dedication and support. Our international network ensures that your air fryer project receives the attention it deserves, no matter where you are located.

Continuous Improvement and InnovationThe appliance industry is constantly evolving, and we stay at the forefront of these changes. Our mold making service is committed to continuous improvement and innovation. We invest in research and development to stay ahead of the curve, ensuring that the air fryers we help produce are equipped with the latest features and technologies.

In conclusion, when it comes to your air fryer needs, our mold making service offers a comprehensive solution that combines precision, customization, rapid prototyping, cost-effectiveness, sustainability, material expertise, global reach, and a commitment to innovation. By choosing us, you’re not just getting a mold; you’re getting a partner who is dedicated to helping your product succeed in the market.

In today’s rapidly evolving kitchen appliance industry, OEM air fryers have become a beacon of innovation and efficiency. They represent more than just a cooking device; they are a testament to how technology can enhance health, convenience, and sustainability. As we reflect on the journey from concept to market-ready air fryer, it’s clear that these appliances are not just shaping the present but also defining the future of culinary experiences.

The demand for healthier cooking options has surged, driven by consumers who are increasingly conscious of their dietary choices. This shift has given rise to the air fryer as a favorite among those looking to enjoy their favorite fried foods without the guilt. The secret lies in the technology, which allows for air frying—using hot air to cook food—a method that significantly reduces the amount of oil needed, thus lowering calories and enhancing nutritional value.

The process of creating an OEM air fryer is a meticulous blend of art and science. It begins with an idea, often sparked by a gap in the market or a desire to push the boundaries of existing technology. From this initial spark, the design phase begins. Engineers and designers collaborate closely, sketching out concepts that not only appeal to the eye but also promise performance and functionality that exceed consumer expectations.

One key aspect of this design phase is the mold making service. This service is crucial for turning a conceptual design into a tangible product. High-quality molds are the foundation for precise and durable manufacturing. They must be robust enough to withstand the intense pressure and temperatures of production, yet flexible enough to produce intricate and precise parts. Our mold making service ensures that each mold is a masterpiece in its own right, capable of producing air fryers that are not just functional but also a delight to the senses.

Once the molds are ready, the manufacturing process can begin in earnest. The precision and detail required in the mold-making stage translate into an assembly line that is both efficient and exacting. Each component is carefully selected and integrated, ensuring that the final product is a seamless blend of form and function. The result is an air fryer that not only performs well but also stands out in the market due to its sleek design and innovative features.

The importance of collaboration with industry experts cannot be overstated. Our team includes seasoned professionals who bring years of experience and a deep understanding of the industry’s nuances. They understand the intricacies of the mold-making process and the importance of materials selection. This expertise is invaluable in ensuring that the air fryers we produce are not just competitive but also set new standards for the industry.

Case studies of our OEM air fryer solutions often highlight the success stories of businesses that have leveraged our expertise to launch their own products. For instance, a small startup approached us with a vision for an air fryer that was not only compact and energy-efficient but also had a unique, ergonomic design. Working closely with the startup, we developed molds that captured their vision and helped them bring their product to life. The result was a hit in the market, leading to a strong brand presence and increased sales.

Another case study involved a well-established appliance brand that was looking to refresh its air fryer line. They sought our help to create a model that would appeal to environmentally conscious consumers. We collaborated with them to design an air fryer made from sustainable materials, with a focus on reducing the carbon footprint throughout the product lifecycle. The final product received glowing reviews and contributed to the brand’s reputation for innovation and environmental responsibility.

When it comes to choosing our mold making service for your air fryer needs, there are several compelling reasons. Our reputation for excellence in mold design and manufacturing is well-earned, and our commitment to quality and customer satisfaction is unwavering. We invest in state-of-the-art equipment and employ highly skilled technicians who are dedicated to precision and detail.

Our molds are not just tools; they are the building blocks of a successful product. They must be accurate, reliable, and capable of handling the demands of mass production. With us, you can be confident that your molds will be of the highest quality, ensuring that your air fryers are as durable and efficient as they are attractive.

Moreover, our collaborative approach means we listen to your vision and translate it into reality. Whether you’re a startup or an established brand, our team is ready to work with you every step of the way. We understand that the air fryer market is highly competitive, and we’re here to help you differentiate your product with innovative design and superior functionality.

In conclusion, as we continue to shape the future of kitchen appliances with OEM air fryers, it’s clear that the journey from concept to market-ready product is a complex and rewarding one. Every detail, from the initial design sketches to the final assembly, plays a crucial role in determining the success of a product. By choosing our mold making service, you’re not just getting a mold; you’re gaining a partner who is invested in your success and dedicated to pushing the boundaries of what air fryers can offer.